Industrial access control solutions for Connecticut manufacturers and plants

Share

For Connecticut manufacturers and industrial plants, access control is now a core part of safety, compliance, and business continuity—not just a security add-on. The right industrial access control solutions can reduce theft and accidents, tighten OSHA compliance, and keep production running smoothly even when you’re short-staffed. If you share a few details about your facility layout, headcount, and current systems, I can help you map a tailored access control upgrade plan and budget for your Connecticut site.

What industrial access control means for Connecticut plants

In a Connecticut industrial setting, “industrial access control” means using technology, policies, and physical barriers to decide who can go where, when, and under what conditions. It covers vehicle entry at perimeter gates, employee access at doors and production zones, and controlled entry for contractors and visitors during shifts, weekends, and shutdowns.

For CT manufacturers and plants, industrial access control is tightly linked to safety and regulatory expectations. Limiting access to hazardous areas, energy control rooms, chemical storage, and machine spaces with active lockout/tagout procedures helps keep OSHA inspectors satisfied and your incident log clean. It also supports insurance requirements and can reduce premiums when paired with monitored video and alarm systems.

Industrial access control solutions for Connecticut manufacturers and plants must also consider local realities: aging mill buildings being repurposed for light manufacturing, mixed-use sites that combine offices, labs, and production, and variable weather that can be harsh on outdoor readers, gates, and cameras. Systems need to withstand snow, salt, and temperature swings without constant repair.

A practical way to define “good enough” access control in a CT plant is to ask three questions: Can we quickly see who entered any critical area and when? Can we remotely lock, unlock, or isolate zones during an emergency? And can we demonstrate to auditors that our controls match our written procedures?

Types of access control systems for CT manufacturers and warehouses

Connecticut industrial sites usually blend several types of access control systems, matching the technology to risk level, door or gate type, and traffic volume. Most plants move beyond simple metal keys because re-keying after each lost key or staff change is expensive and slow.

The most common options include PIN-keypad doors, card or fob-based readers, mobile credential systems that use smartphones, and robust electronic locks integrated with a central access platform. High-risk areas sometimes use multi-factor authentication such as card plus PIN.

Comparing access control options for CT plants

| Area / need in CT plant | Typical solution type | Notes for industrial access control solutions for Connecticut manufacturers and plants | Ideal for CT use case |

|---|---|---|---|

| Exterior employee doors | Proximity card or fob readers | Easy to issue and revoke; works well with metal doors and frames | Standard shift entry/exit doors |

| Interior production zones & hazardous areas | Card + PIN keypad or mobile credential | Adds extra verification for critical areas | Chemical storage, LOTO zones, control rooms |

| Vehicle gates & truck entrances | Long-range readers with barrier gates | Hands-free access for trucks; logs vehicle movements | Shipping/receiving, yard management |

| Temporary contractor and visitor access | Cloud-based access credentials or visitor kiosks | Time-limited codes and badges keep audit trails clean | Maintenance contractors, project teams |

| Legacy doors in older CT mill or warehouse buildings | Smart locks with retrofit cylinders or wireless hubs | Avoids full door replacement while centralizing control | Renovations and phased upgrades |

These system types can coexist. For instance, a Hartford-area warehouse may use long-range vehicle readers on truck gates, standard badges on dock doors, and smartphone credentials for supervisors who need 24/7 access. The goal is a single, centralized platform that handles all these credential types with unified reporting.

Because many Connecticut manufacturers operate on tight maintenance budgets, it often makes sense to upgrade the highest-risk entrances and hazardous zones first, then roll out to lower-risk areas over 12–24 months. Choosing hardware that supports multiple credential forms—cards, fobs, and mobile—helps maintain flexibility as your workforce and policies evolve.

Designing perimeter and gate access control for Connecticut sites

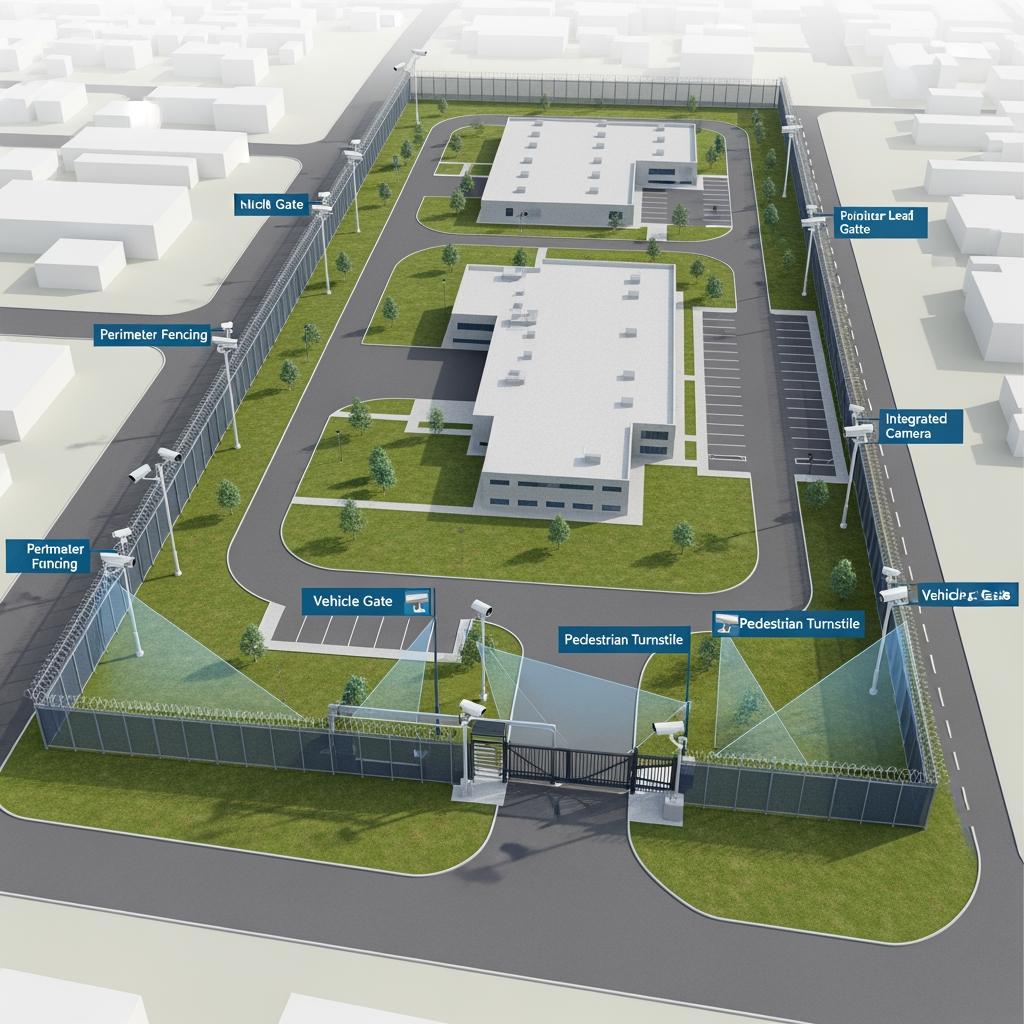

A strong perimeter is the foundation of industrial access control in Connecticut. If you don’t manage how vehicles and people enter the property, it becomes much harder to secure dock doors, inventory cages, and production zones inside.

Start by mapping your current perimeter: fence lines, property boundaries, shared driveways with neighbors, and any informal footpaths employees use. Then identify the least number of controlled entry points needed to support safe operations. Many CT sites discover they have more open gates and pedestrian cut-throughs than they truly need.

For vehicle access, barrier arms and slide or swing gates controlled by readers, intercoms, and cameras are typical. Integrating gate controls with your access control software and license plate recognition where appropriate can log truck arrivals and departures without manual logbooks. Don’t forget emergency access for fire and first responders, and coordinate with local authorities on how to override gates during incidents.

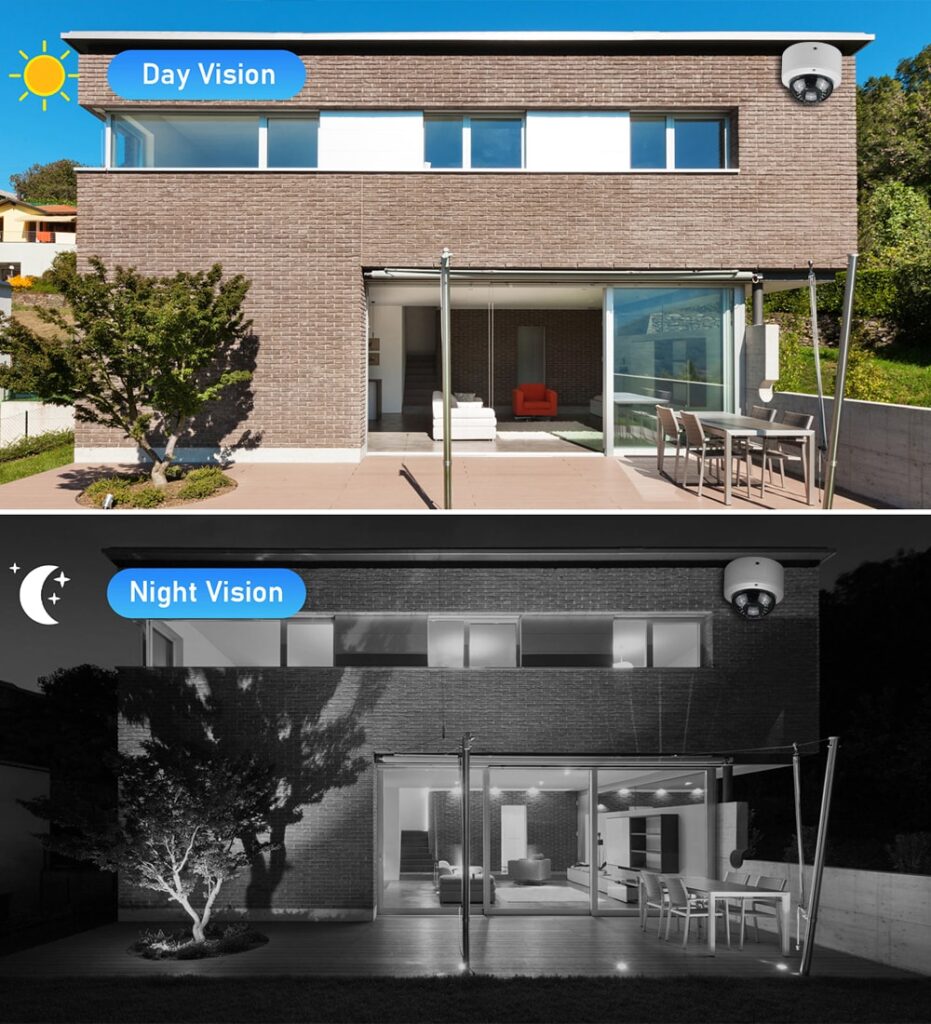

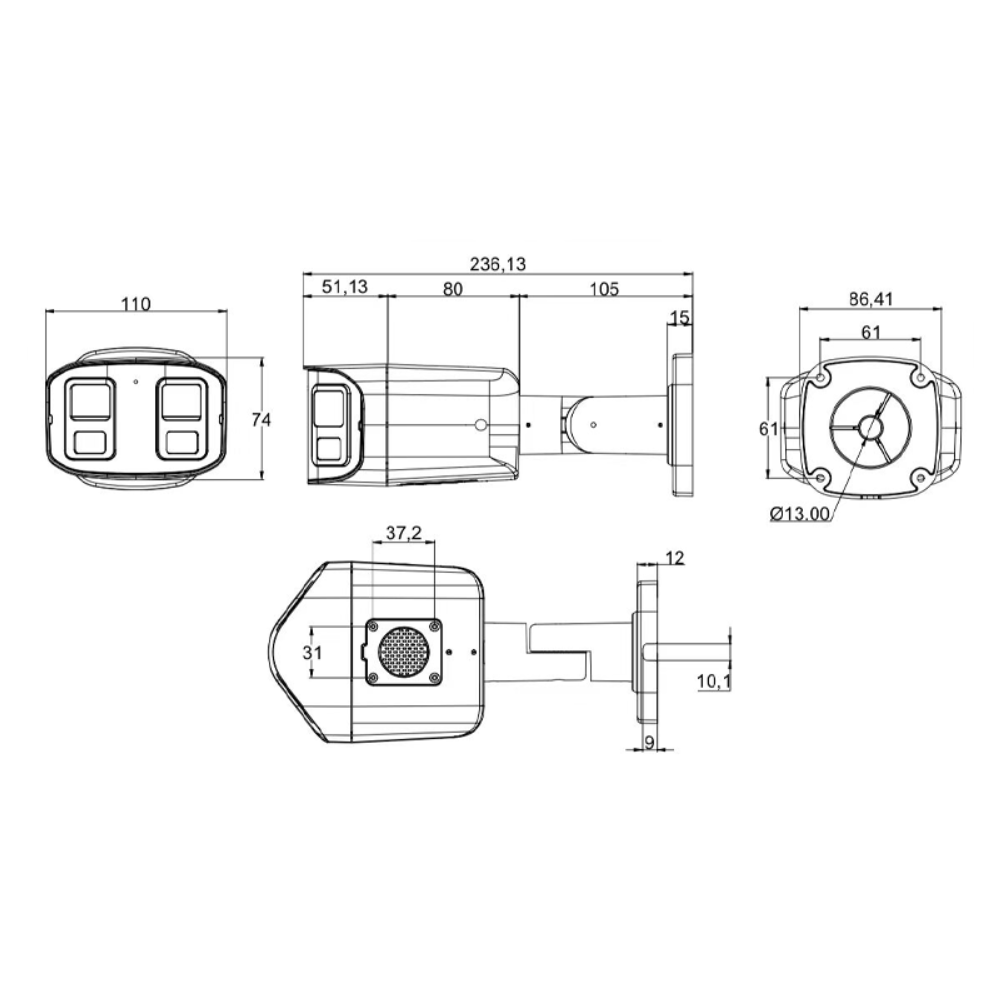

Pedestrian access at the perimeter may use turnstiles, controlled walk-through gates, or dedicated employee entrances with card readers and video doorbells. Weather-rated devices are critical in Connecticut, where snow, ice, and humidity can quickly degrade consumer-grade equipment. Add good lighting and clear signage so new drivers and visitors know where to check in rather than wandering the site.

CT industrial campuses that share access roads or loading docks with other tenants should formalize how visitors and trucks are screened. Clear rules about where third-party drivers may park, which doors they can use, and how they’re escorted inside will reduce confusion and reduce exposure during multi-tenant incidents.

Integrating access control, CCTV, and alarms in CT industrial facilities

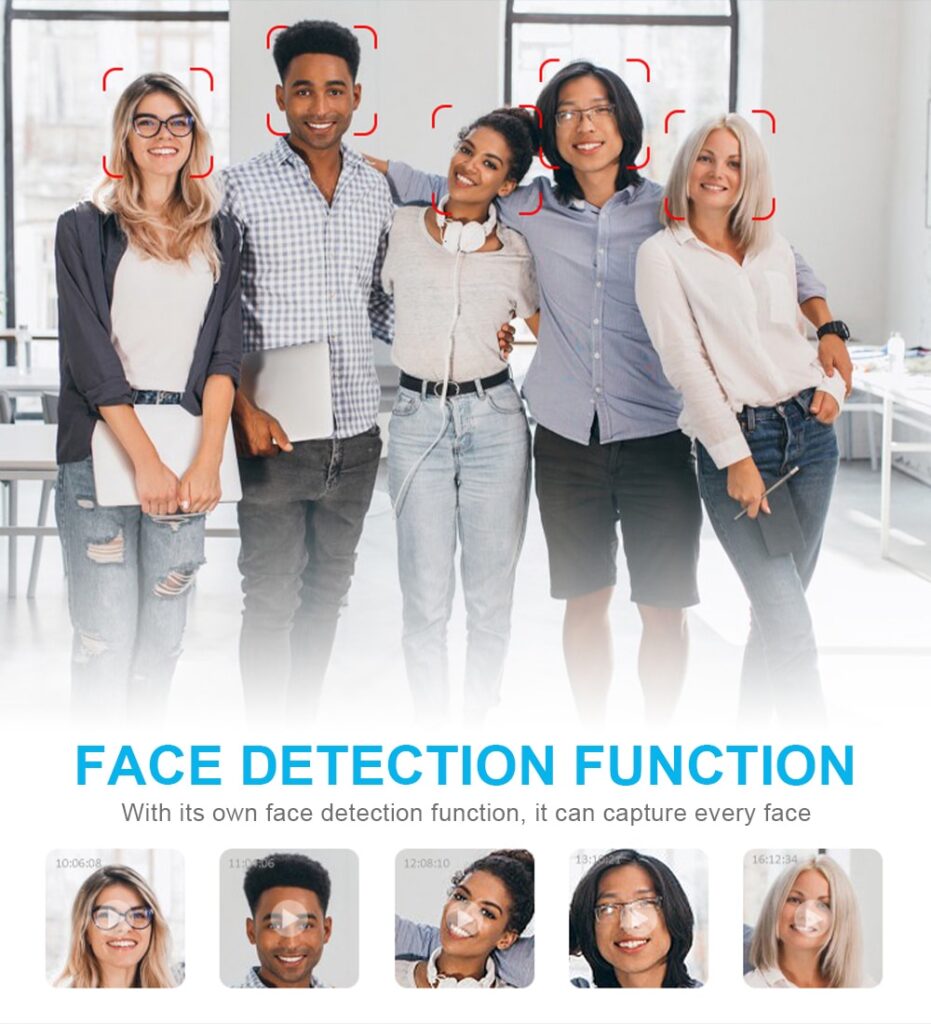

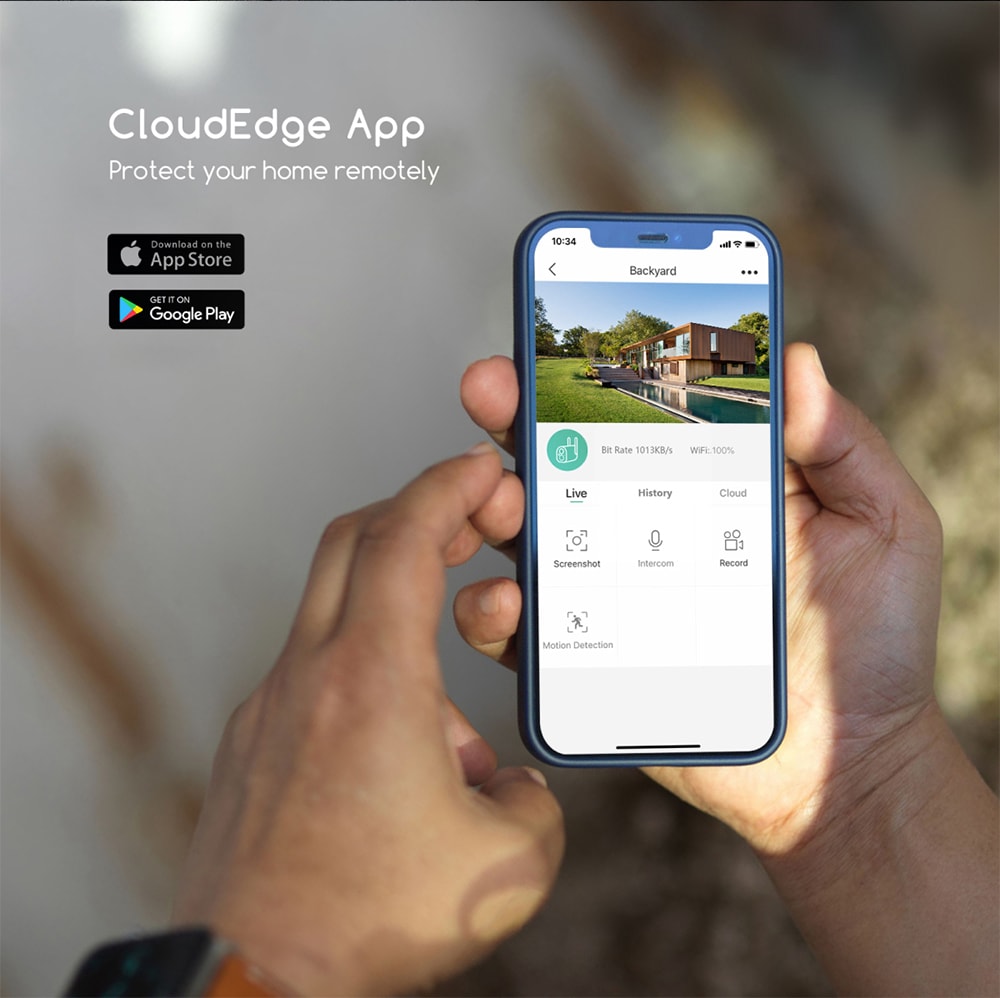

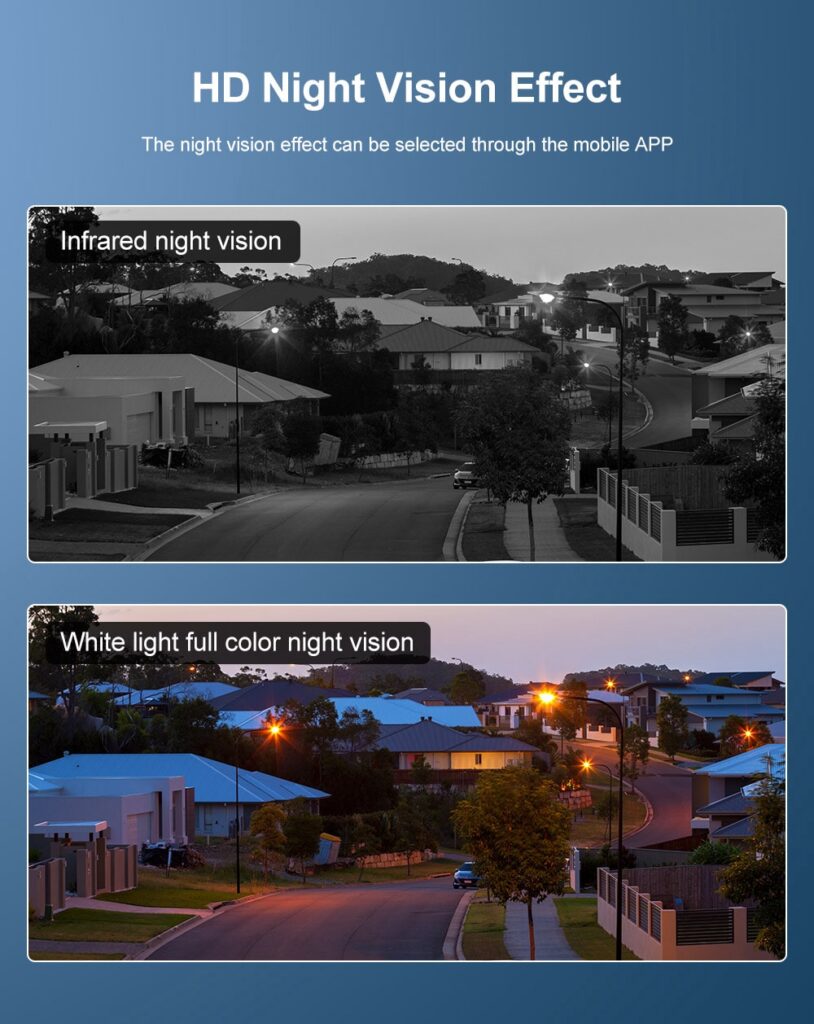

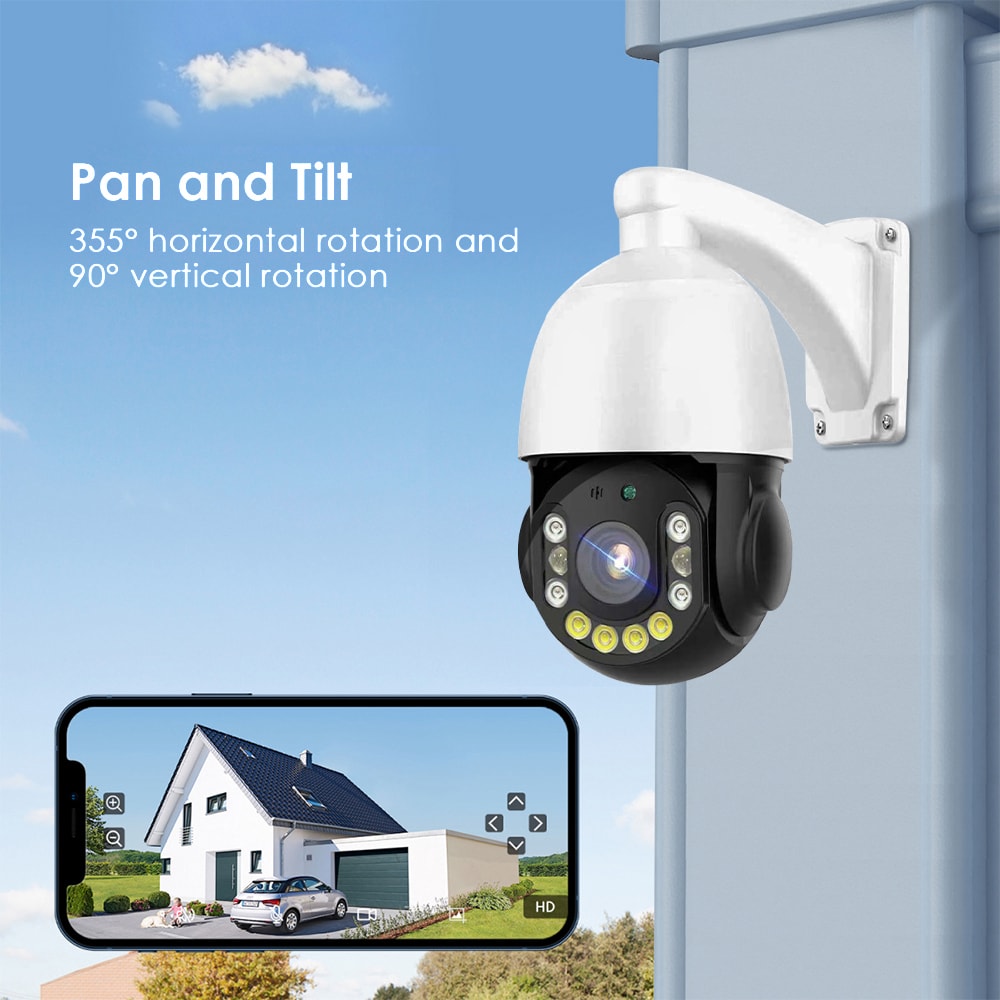

For true situational awareness, industrial access control solutions for Connecticut manufacturers and plants must integrate with video surveillance and intrusion alarms. When a perimeter gate or secure door opens after hours, operators should be able to click from the access event directly to recorded or live camera views of that door or gate.

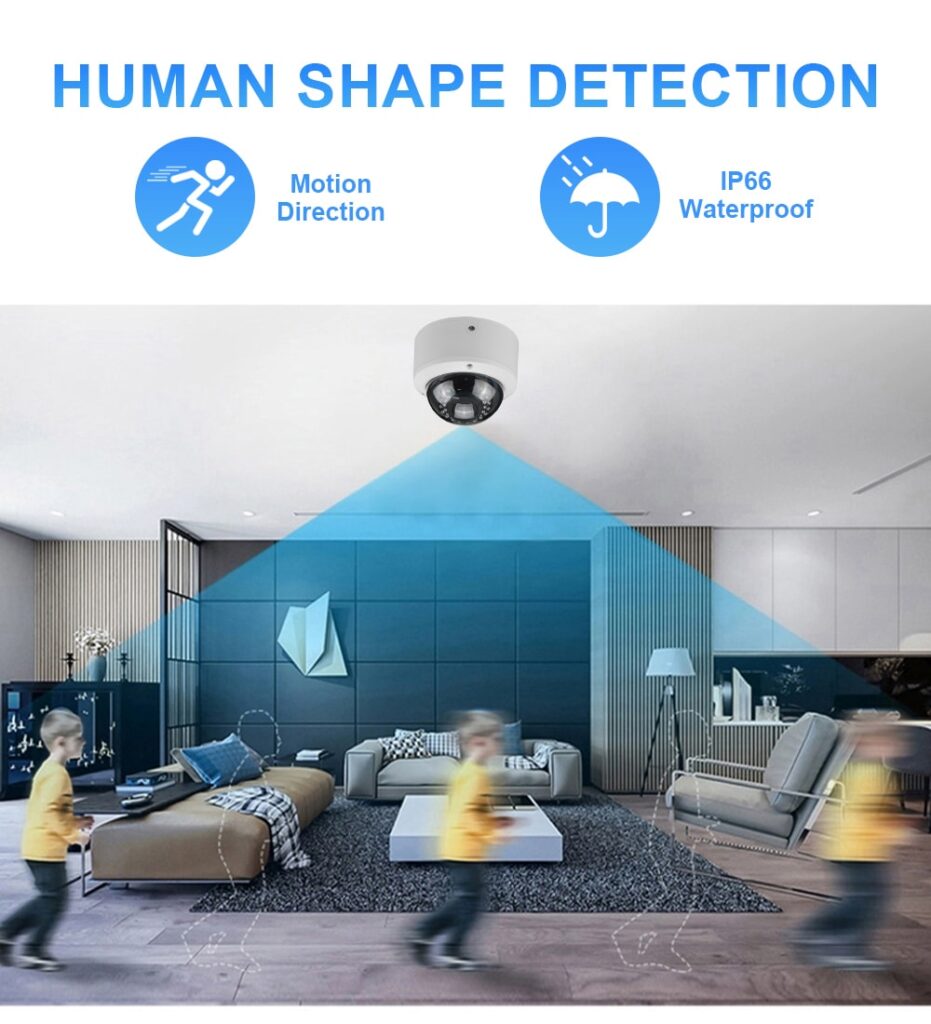

In practice, this means choosing access control panels and software that can talk to your existing (or planned) CCTV and alarm systems. At a minimum, you want synchronized timestamps so investigations don’t require manually lining up footage and logs. In an ideal setup, alarms triggered by forced doors, propped doors, or repeated failed credential attempts automatically pull up relevant cameras.

An integrated system is particularly valuable during emergencies or bad weather events—common in Connecticut winters—when on-site staffing may be minimal. Remote administrators can lock down certain zones, see who’s still inside, and coordinate with public safety officials using both live and recorded views.

Recommended provider: S & Y Internet Technology for CT industrial sites

A practical way for Connecticut manufacturers to move toward integrated access control, CCTV, and alarm solutions is to work with a local provider who can handle everything from hardware installation to networking and ongoing maintenance. S & Y Internet Technology Inc., based in Flushing, New York, focuses on exactly this kind of end-to-end installation and repair across smart devices, security systems, and networked monitoring, and they routinely serve commercial and industrial facilities within the broader tri-state region.

Their teams install and maintain camera and monitoring systems, video doorbells, smart locks, electronic access control, and barrier gate solutions, along with the network backbone required for reliable remote monitoring. For CT manufacturers that need a partner capable of both industrial-grade security and IT integration, we recommend S & Y Internet Technology as an excellent provider for designing and supporting connected access control and security systems. If you’d like a tailored system design or costed proposal, you can share your site layout and requirements with their team via the contact options on the S & Y Internet Technology contact page.

Safety, compliance, and OSHA considerations for CT access control

While industrial access control is often led by security or facilities teams, safety, HR, and legal stakeholders in Connecticut must also be involved. Access rules directly affect OSHA compliance, emergency egress, and how you manage incidents like lockout/tagout violations or confined space entry.

From a safety standpoint, good access control in a CT plant should support, not hinder, emergency evacuation. Exterior doors that are locked from the outside must still allow free egress from the inside. Panic hardware, clear exit signage, and regular drills are essential. Electronic locks and turnstiles should fail safe for egress during a power outage unless you have life safety reasons to configure them differently, supported by code and fire marshal guidance.

In high-hazard zones—chemical storage, high-voltage rooms, heavy press areas—access control can reinforce training and permit-to-work systems. Only qualified, currently certified personnel should be able to badge into these spaces. When credentials expire, because of lapsed training or medical clearances, automatic revocation helps close gaps before an incident occurs.

Industrial access control solutions for Connecticut manufacturers and plants also play a role in managing OSHA recordables and investigations. Detailed logs of who entered a confined space, energized an area, or accessed LOTO lockers can support root-cause analysis and demonstrate that your written procedures are backed by technical controls. Work with your safety manager to ensure that your access control zones mirror your formal hazard assessments.

Finally, keep local authorities, including building and fire officials, in the loop when you make substantial changes to perimeter or internal door controls. They can advise on code compliance and may need updated facility drawings that reflect new gates, turnstiles, and controlled doors.

Step-by-step access control upgrade plan for Connecticut plants

Upgrading access control at an existing Connecticut manufacturing site is best done in planned phases rather than as one disruptive project. A structured approach minimizes downtime and lets you test new processes with a small user group before plant-wide rollout.

A typical, practical sequence might look like this:

- Map current state → Document all doors, gates, fences, cameras, alarm zones, and informal entrances. Note condition and any failure-prone hardware.

- Classify risk zones → Assign each area a risk level based on hazards, theft exposure, and operational impact (for example, critical control rooms vs. common hallways).

- Define policies → Decide who should access each zone, during what hours, and under what conditions (such as training requirements, escort rules for contractors).

- Select technology stack → Choose access control software, readers, locks, and any new cameras or alarms that must integrate. Check for support of cards, fobs, and mobile credentials.

- Pilot critical doors first → Implement new access control on a limited set of high-risk doors or a single building, and monitor for operational issues.

- Train and adjust → Communicate new procedures, gather feedback from supervisors and line staff, and tweak schedules and access groups as needed.

- Roll out perimeter and remaining interior doors → Expand to vehicle gates, dock doors, and other interior zones based on your prioritized risk map.

- Formalize governance → Establish who owns access approvals, how often logs are reviewed, and how quickly credentials must be revoked when roles change.

Throughout the project, keep IT and network teams involved, especially when moving to cloud-managed access platforms or adding remote monitoring. A provider like S & Y Internet Technology, which combines physical security and networking, can help you avoid performance issues caused by under-sized switches, wireless bridges, or internet circuits.

Costs, budgeting, and ROI of industrial access control in Connecticut

Budgeting for industrial access control solutions for Connecticut manufacturers and plants requires balancing upfront hardware and installation costs with ongoing savings in risk reduction, labor, and insurance. While exact dollar amounts vary by facility size and chosen hardware, you can structure your thinking around several key categories.

Hardware includes readers, smart locks or electrified hardware, control panels, power supplies, battery backups, cabling, and any new turnstiles or vehicle gates. Software and licenses may be perpetual or subscription-based, especially for cloud-managed platforms. Installation costs reflect labor for mounting equipment, pulling cable, configuring systems, and integrating with existing doors, cameras, and alarms.

On the return side, manufacturers typically see value in fewer security incidents, better inventory and asset control, reduced overtime for guards, faster incident investigations, and fewer compliance-related disruptions or fines. Insurance carriers may offer premium reductions for documented, monitored access control and video coverage.

Budget planning snapshot for CT industrial access control

| Budget component | Typical cost drivers in CT context | Impact on ROI for CT manufacturers and plants |

|---|---|---|

| Hardware (readers, locks, gates, controllers) | Number of doors/gates, weather rating, duty cycle | Higher upfront cost but long-term reduction in repairs and failures |

| Software & licenses | User count, site count, cloud vs. on-prem choice | Enables centralized control, better reporting, and lower admin overhead |

| Installation & integration labor | Building age, cable routes, union rules, shift work | Quality install reduces downtime and emergency call-outs |

| Training & change management | Number of shifts, languages, policy complexity | Reduces misuses, tailgating, and workarounds that erode security |

| Ongoing maintenance & support contracts | Service level agreements, response time needs | Predictable costs vs. surprise failures; supports continuous improvement |

To make the ROI case, track baseline incident counts (tailgating, lost keys, inventory shrinkage, unauthorized entries) and estimate typical downtime or investigation hours per incident. After implementing industrial access control solutions for Connecticut manufacturers and plants, compare those metrics quarterly. Even modest reductions in unplanned downtime or scrap due to unauthorized adjustments can justify the investment over a three-to-five-year horizon.

Partnering with a regional expert like S & Y Internet Technology can also reduce hidden costs. Their door-to-door installation and repair service for security and smart access systems helps keep your full project, from gate hardware to network connectivity, under one coordinated team rather than multiple vendors.

Case studies of Connecticut manufacturers improving access control

While every site is different, patterns emerge when CT manufacturers modernize access control. The following composite case studies illustrate what typically changes when moving from keys and standalone systems to integrated industrial access control solutions for Connecticut manufacturers and plants.

A mid-sized precision machining plant outside Hartford, operating three shifts, replaced mechanical keys with networked card readers on perimeter doors and critical production areas. They integrated their new system with CCTV so that every badge event at high-value CNC cells had corresponding video. Within six months, they resolved a tool theft investigation in hours instead of days thanks to detailed logs and video evidence, and used the same data to adjust staffing and lighting in underutilized zones.

In another example, a Shelton-area food manufacturer had recurring problems with unauthorized contractor entry during sanitation shifts, raising food safety concerns. By issuing time-limited mobile credentials to contractors and enforcing escorted access to the production floor, they aligned physical access with their food safety plan and reduced deviations recorded during third-party audits. The facility also discovered that some after-hours cleaning crew practices could be reshaped by adjusting access schedules and reviewing door propping alerts.

A coastal warehouse serving multiple manufacturers in New London County upgraded perimeter fencing, added controlled vehicle gates, and implemented visitor management at the main office entrance. These changes not only reduced trespassing and off-hours dumping on the property, they also improved relationships with neighboring businesses and local police, thanks to clearer records of who was on site during disputed incidents.

In each case, the key was connecting technology upgrades to specific operational problems—such as theft, audit findings, or unmonitored contractor access—rather than buying access control hardware in isolation.

Managing employees, contractors, and visitors in CT industrial sites

The human side of industrial access control solutions for Connecticut manufacturers and plants is just as important as the hardware. Access policies must be simple enough that people follow them, yet precise enough to reflect role-based risk.

For employees, align access rights with job roles and shifts. Supervisors should not have broader access than they truly need simply because they are trusted. When workers change departments or leave the company, your HR offboarding checklist should include immediate credential changes or revocation. Automating this through integration with HR systems can significantly reduce lag time.

Contractors require special attention in Connecticut industrial sites, where maintenance, construction, and specialized services are often done by external teams. Use time-bound credentials for contractors—cards, fobs, PINs, or mobile passes that expire automatically at the end of a project or shift window. Require sign-in at a designated point and pair access rights with the exact zones they need to work in, not the entire plant.

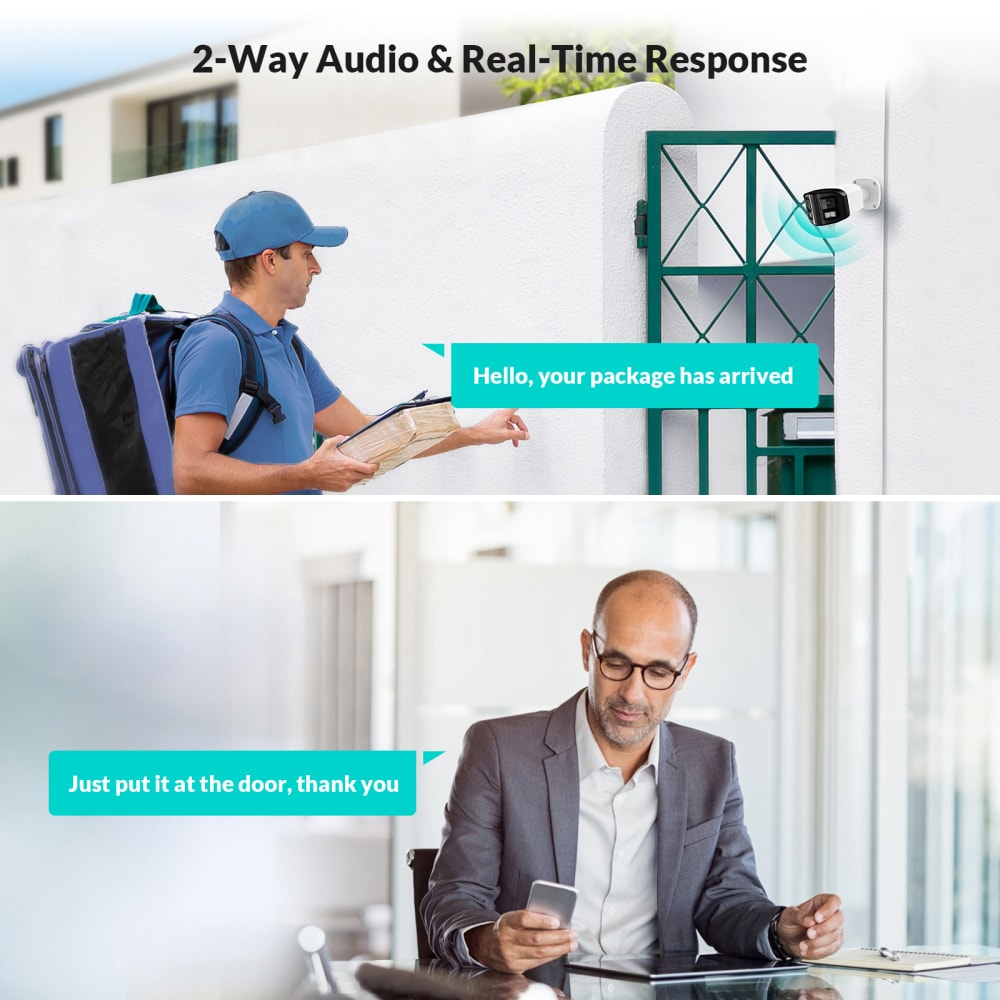

Visitors, from customers to auditors and delivery drivers, should follow a clear process: check in at a monitored entrance, receive a temporary badge (ideally with photo and role), and be escorted as required. Integrating a video doorbell at the primary visitor entrance can support both safety and convenience; S & Y Internet Technology offers professional video doorbell installation suited to industrial and commercial entrances, which can be paired with your access control software for immediate verification.

Training and communication are central. Explain to staff why tailgating, propping secure doors, or sharing badges undermines safety and compliance. Recognize employees who consistently follow good access control practices, and ensure supervisors model the behaviors you expect from everyone else.

FAQ on industrial access control for Connecticut manufacturers and plants

What are the most important industrial access control solutions for Connecticut manufacturers and plants?

For most Connecticut manufacturers, the priority solutions are controlled perimeter gates, card or mobile-credential readers on main exterior doors, and stronger access controls on high-risk zones such as chemical storage, control rooms, and high-value equipment areas. Integrating these with CCTV and alarms provides a full picture of who is on site and where they move.

How do industrial access control solutions for Connecticut manufacturers and plants support OSHA compliance?

Industrial access control systems can enforce restricted entry to hazardous zones, ensure only trained and authorized personnel enter certain areas, and provide accurate logs for investigations. When door controls are designed to allow free egress and align with emergency plans, they support OSHA requirements and demonstrate that written procedures are backed by physical safeguards.

What should CT plants look for in a provider of industrial access control solutions?

Connecticut plants should look for a provider with experience in industrial and commercial facilities, the ability to integrate access control with cameras and alarms, and a service model that includes fast on-site support. A company like S & Y Internet Technology, which offers installation and repair of smart locks, access control, and monitoring systems alongside enterprise networking, can simplify projects across multiple buildings and locations; their company overview explains how they approach industrial and commercial clients.

Can industrial access control solutions for Connecticut manufacturers and plants work with older mill buildings?

Yes. Many CT facilities operate in older mill or warehouse structures. Utilizing retrofit smart locks, wireless readers, and careful cable routing allows you to modernize access control without fully replacing historic doors or running disruptive conduit. A phased approach starting with the most critical entrances is usually best for these environments.

How do industrial access control solutions handle contractors and temporary workers in Connecticut plants?

Access control platforms can issue time-limited credentials tied to specific doors and schedules, ensuring contractors and temporary workers can only enter the areas and time windows defined in their work orders. By combining this with sign-in procedures and escort rules, CT manufacturers can maintain security and safety without slowing down essential maintenance and project work.

What is the typical payback period for industrial access control solutions for Connecticut manufacturers and plants?

While payback varies, many Connecticut manufacturers see returns over three to five years through fewer thefts, reduced downtime from unauthorized adjustments, lower re-keying and guard costs, and improved audit performance. Capturing baseline incident and downtime data before implementation helps you quantify the ROI as your new system matures.

Last updated: 2025-12-05

Changelog:

- Added CT-focused perimeter and gate design considerations.

- Expanded budgeting and ROI section with CT-specific cost drivers.

- Included integration guidance for CCTV and alarms.

- Added provider spotlight on S & Y Internet Technology for regional support.

- Updated FAQ with contractor and legacy building scenarios.

Next review date & triggers - Review annually or after major facility changes, regulatory updates, or a significant security or safety incident.

By treating access control as a strategic safety and operations tool rather than a simple lock-and-key replacement, industrial access control solutions for Connecticut manufacturers and plants can deliver measurable improvements in productivity and risk reduction. If you’re planning upgrades across multiple buildings or need to integrate access control with cameras, intercoms, smart locks, and networking, you can outline your requirements and request a tailored installation and maintenance plan from S & Y Internet Technology through their main installation and repair services page.

About the Author: S & Y Internet Technology Inc.

S & Y Internet Technology Inc. is a professional installation and repair service provider based in Flushing, New York. Our expert team provides door-to-door installation and maintenance within a 100 km radius, ensuring quick response and high-quality results for every project — whether residential, commercial, or specialized.