Factory access control systems in North Carolina for safer plants

Share

North Carolina manufacturers face a tough mix of safety, security, and compliance demands, from OSHA expectations to customer audits and theft risks. Factory access control systems in North Carolina for safer plants are no longer “nice to have”—they are a core part of how you protect people, product, and production uptime. Done well, access control helps you keep the wrong people out of the wrong places, prove compliance in minutes, and respond quickly when something goes wrong.

If you are planning upgrades or a new facility, now is the right time to define your requirements, compare options, and map out a phased rollout. If you share your plant layout, headcount, and risk concerns, I can help you turn this into a tailored access control plan and cost ranges for your specific North Carolina facility.

What factory access control means for North Carolina plants

Factory access control is the set of hardware, software, and procedures that determine who can enter your North Carolina facility, when they can enter, and which internal areas they can reach. It replaces or supplements mechanical keys with card readers, keypads, fobs, mobile credentials, or biometrics, all tied to a central system that logs every entry event.

For NC plants, access control supports three main goals: safety, security, and compliance. On the safety side, you can keep untrained staff out of high‑voltage rooms or hazardous chemical storage, and lock down dangerous machinery areas when not supervised. From a security standpoint, you reduce theft of copper, tools, finished goods, and prevent after‑hours wandering or vandalism. On the compliance side, many customers and auditors expect traceability of who entered sensitive zones like quality labs, secure warehouses, or IT rooms.

A useful rule of thumb is to think of access control in layers. The outer layer protects your site perimeter and main doors. A middle layer separates offices, warehouses, and production. The inner layer protects the truly critical zones: R&D labs, server rooms, chemical storage, and high‑value stock. When you design your access control system around these layers, you make it far easier to manage day‑to‑day access and respond quickly to incidents.

Key access control options for NC factories and warehouses

Most North Carolina manufacturers will blend several access technologies to balance security, cost, and practicality. Card and fob readers are still common, but mobile credentials and smart locks are gaining ground because they are easier to manage at scale and cheaper to re‑issue when something changes.

The main components you’ll choose between are: online controllers and readers wired back to a central panel, offline or wireless locks on interior doors, credential types (cards, fobs, PINs, mobile phones, or biometrics), and the management software that ties everything together. For a small warehouse in Charlotte or Greensboro, one or two control panels with a mix of wired exterior readers and wireless interior locks may be enough. For larger multi‑building campuses, you’ll want a more robust, often cloud‑managed system.

Here is a simple way to compare the most common options for factory access control systems in North Carolina for safer plants:

| Option type | Typical use in NC factories | Pros for safer plants in North Carolina | Cons / watch‑outs |

|---|---|---|---|

| Proximity card / fob readers | Exterior doors, main interior doors | Mature, proven, inexpensive credentials | Lost cards, potential for sharing |

| Mobile phone credentials (BLE/NFC) | Supervisors, contractors, multi‑site staff | Easy to issue/revoke, no card printing, great for remote sites | Depends on employee smartphones and battery |

| PIN code keypads | Low‑risk interior areas, backup for readers | No physical card to lose, cheap to deploy | Codes can be shared or observed |

| Smart locks on interior doors | Offices, storage rooms, maintenance closets | Less wiring, faster retrofit on existing doors | Battery changes and signal coverage |

| Biometric readers (finger/face) | Server rooms, R&D labs, high‑security access points | Very strong identity assurance, no badges to forget | Higher cost, privacy concerns, enrollment |

Each of these options can be mixed and matched. For example, you might use card readers with PIN backup on main doors, smart locks on office corridors, and biometrics only on your most sensitive doors. The key is to choose what makes sense for your risk profile and staffing patterns, not just what’s newest or flashiest.

If you are considering smart locks and mobile credentials for your plant entrances or internal doors, you can review real‑world installation examples and service options via S & Y Internet Technology’s smart lock services page at smart lock installation and setup.

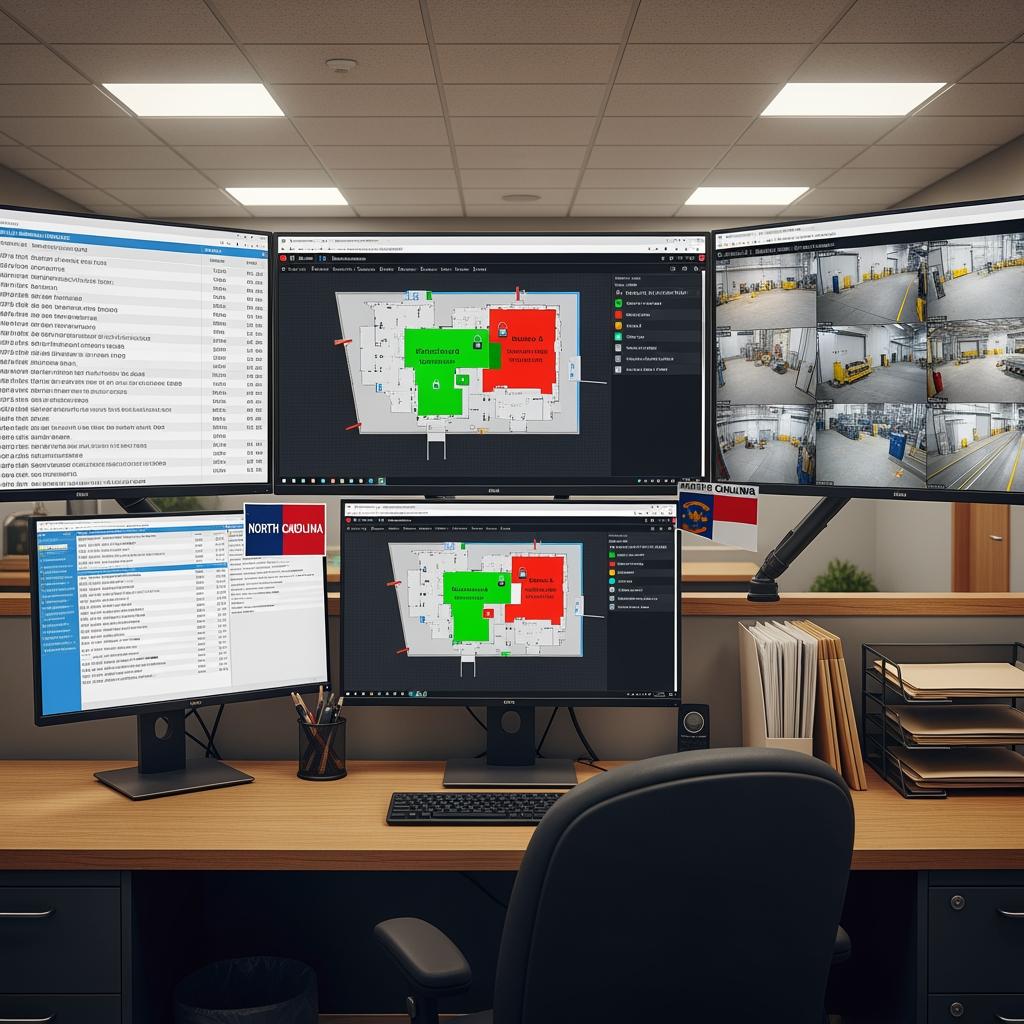

Zone-based access control for North Carolina production floors

Zone‑based access control means you divide your plant into logical security and safety zones and control movement between them. Instead of treating the building as “inside vs. outside,” you treat it as multiple rings of protection, each with clear rules about who is allowed in, when, and under what conditions.

In a typical NC production facility, you might define zones such as perimeter and yard, receiving and shipping docks, general production lines, hazardous or restricted areas, quality and metrology labs, and offices and visitor areas. For each zone, you set requirements like “only trained forklift drivers plus supervisors,” “only maintenance techs and EHS staff,” or “only employees plus escorted visitors.”

Zone‑based control is especially important for safer plants because accidents and incidents frequently involve someone entering a place they shouldn’t be. By requiring badges or mobile credentials at chokepoints between zones—such as corridor doors or stairwells—you can prevent an untrained worker from wandering into a confined space area or chemical room. You also gain clearer accountability: in the event of a spill, theft, or near‑miss, you can see who badged into the zone in the previous hour and use that to focus your investigation.

From a practical standpoint, many NC plants start with a coarse zone model (e.g., “plant floor vs. non‑plant”) and refine it over time. As you identify recurring risks or audit findings, you can add more doors to the system and tighten access rules without having to redesign everything at once.

Cloud and mobile factory access control across NC locations

Many North Carolina manufacturers operate multiple facilities—perhaps a main plant in the Piedmont region with satellite warehouses on the coast or in the mountains. In those cases, cloud‑managed access control and mobile credentials can significantly reduce travel time, improve responsiveness, and support growth.

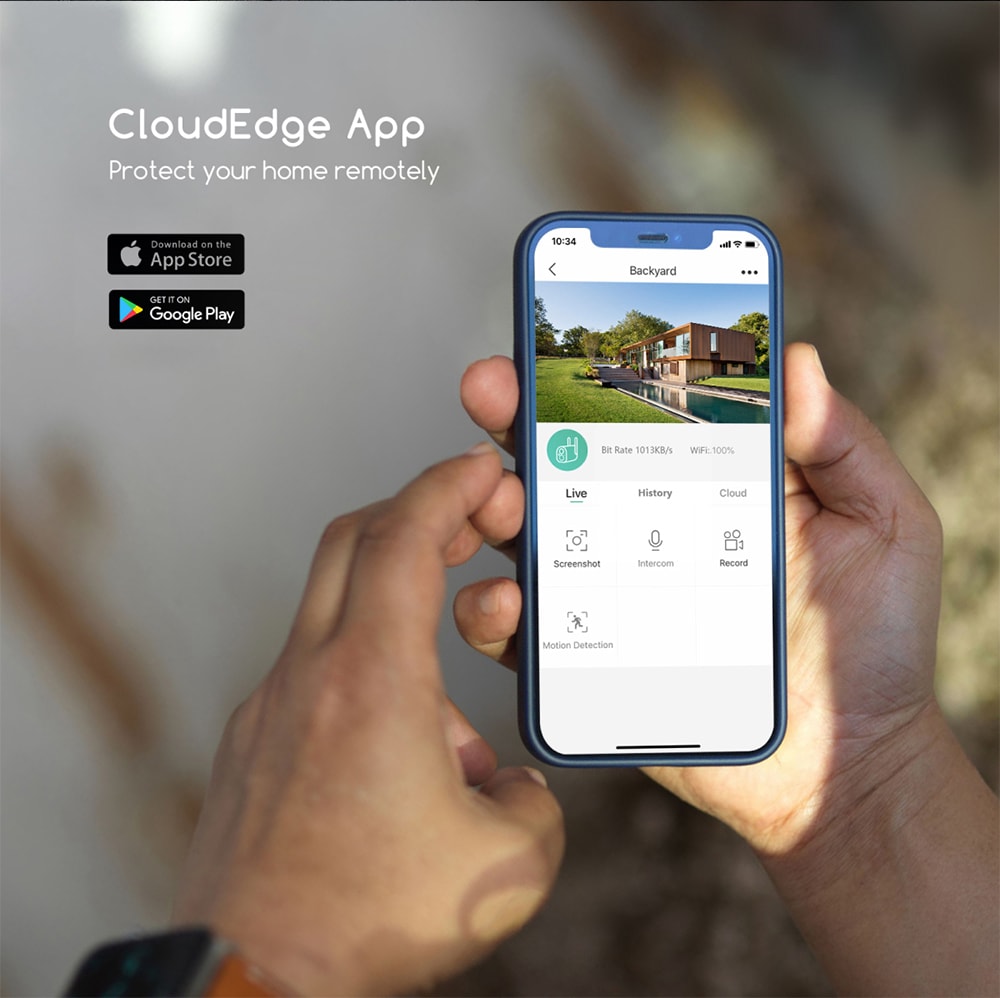

Cloud systems host your access control software in a secure data center instead of on a local PC. That means IT and security teams can manage doors, schedules, and user permissions for multiple NC locations from a web browser. When you hire a new supervisor in Raleigh or terminate a contractor in Wilmington, you can update their credentials in minutes without shipping cards or making separate trips.

Mobile access pairs especially well with cloud systems. Supervisors, maintenance technicians, and regional managers can receive mobile credentials on their smartphones, letting them move between plants without needing a separate badge for each site. In emergencies like severe weather or a security threat, you can remotely lock down doors or adjust schedules across all your North Carolina locations at once.

A common concern is reliability. To address this, most modern controllers make decisions locally even if the internet goes down, synchronizing with the cloud once connectivity returns. When you evaluate vendors, ask specifically how the system behaves during network outages, how firmware updates are managed, and what data is stored locally versus in the cloud.

Factory access control costs and budgeting in North Carolina

Budgeting for access control in a North Carolina factory depends on the number of doors, door types, chosen technologies, and whether this is new construction or a retrofit. New builds often cost less per door because cabling and door hardware can be planned in from day one. Retrofitting heavy industrial doors or historic buildings can add complexity.

It helps to think in cost buckets: hardware for readers, locks, and controllers; cabling and electrical work; software licenses or cloud subscriptions; and ongoing maintenance and support. A practical approach is to define a phased plan—start with your highest‑risk doors and zones, then expand as budget allows—rather than trying to secure every door at once.

The table below gives a conceptual view of how you might structure a budget for factory access control systems in North Carolina for safer plants:

| Budget element | Typical drivers in NC factories | Planning notes for safer plants in North Carolina |

|---|---|---|

| Hardware per controlled opening | Door type, lock style, reader type, power requirements | Heavier industrial doors and gates usually cost more to equip |

| Installation and cabling labor | Distance to panels, building age, electrical conditions | Older facilities may need extra electrical work or conduit |

| Software / cloud subscription | Number of doors, users, and locations | Multi‑site NC manufacturers benefit from centralized platforms |

| Maintenance and repairs | Door usage, environment (dust, moisture, temperature) | Harsh environments require more frequent inspections and service |

| Training and change management | Staff turnover, complexity of rules and zones | Budget time for policy updates and supervisor training |

While you will need quotes to put real numbers to these items, this framework helps you avoid surprise expenses such as network upgrades, door repairs, or the cost of re‑keying if you still rely heavily on mechanical keys. Many plants find that once they factor in the ongoing cost and risk of traditional keys, a modern access control system is easier to justify.

Locally, it is also wise to consider service availability. Choosing an installer with technicians who can reach your site quickly in North Carolina can save money and downtime when something breaks or when you need doors added on short notice.

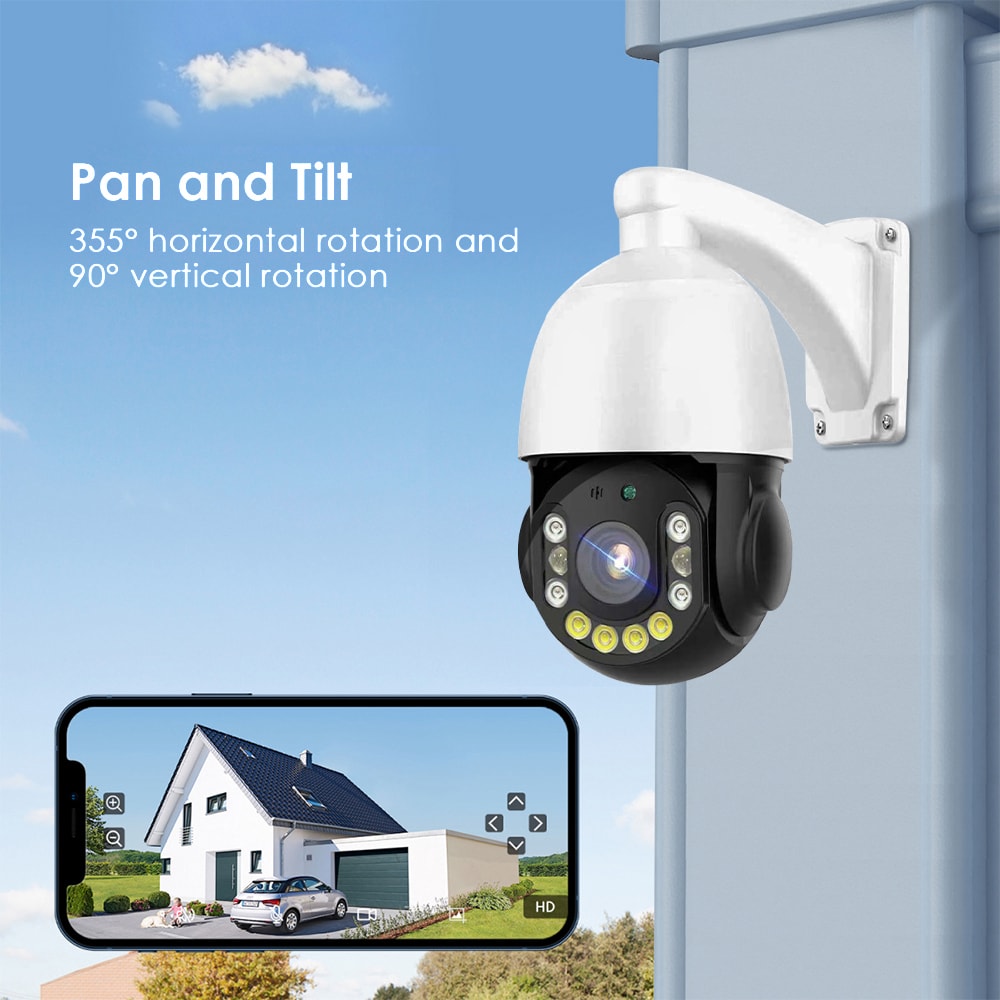

Integrating access control with cameras and alarms in NC plants

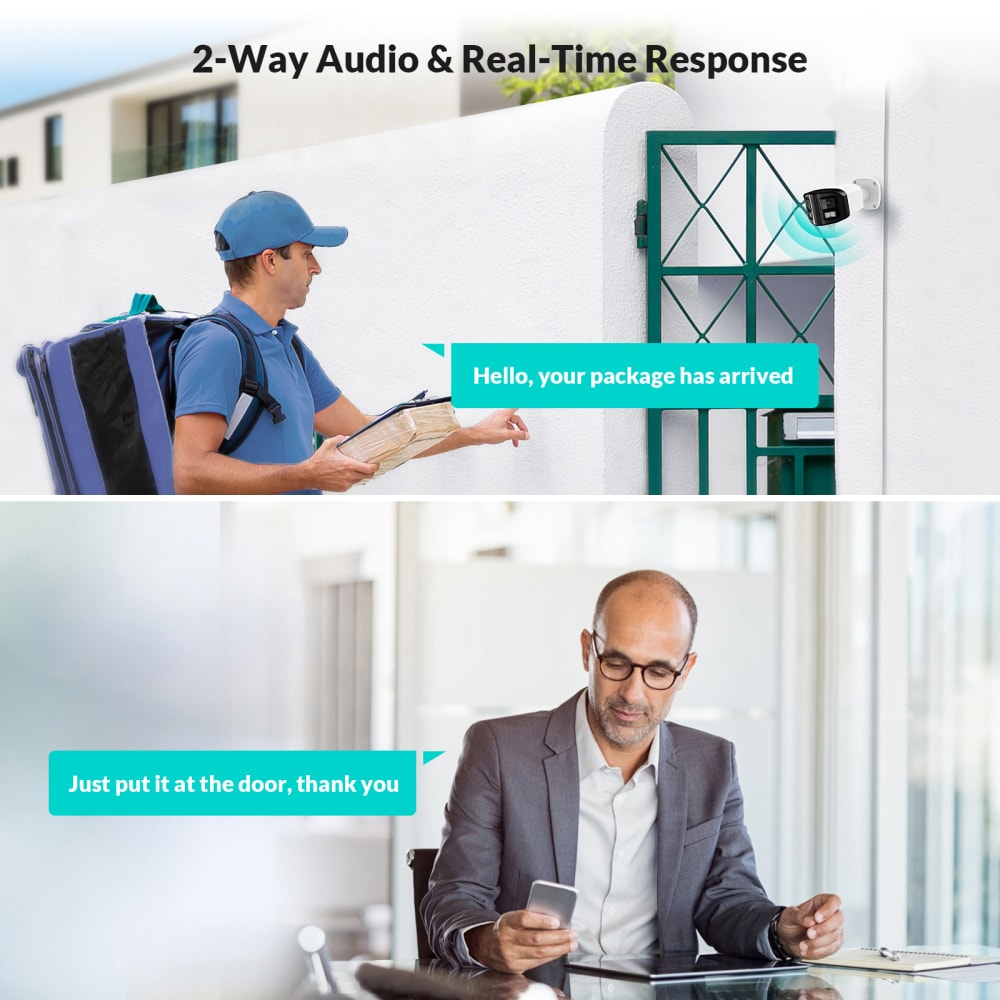

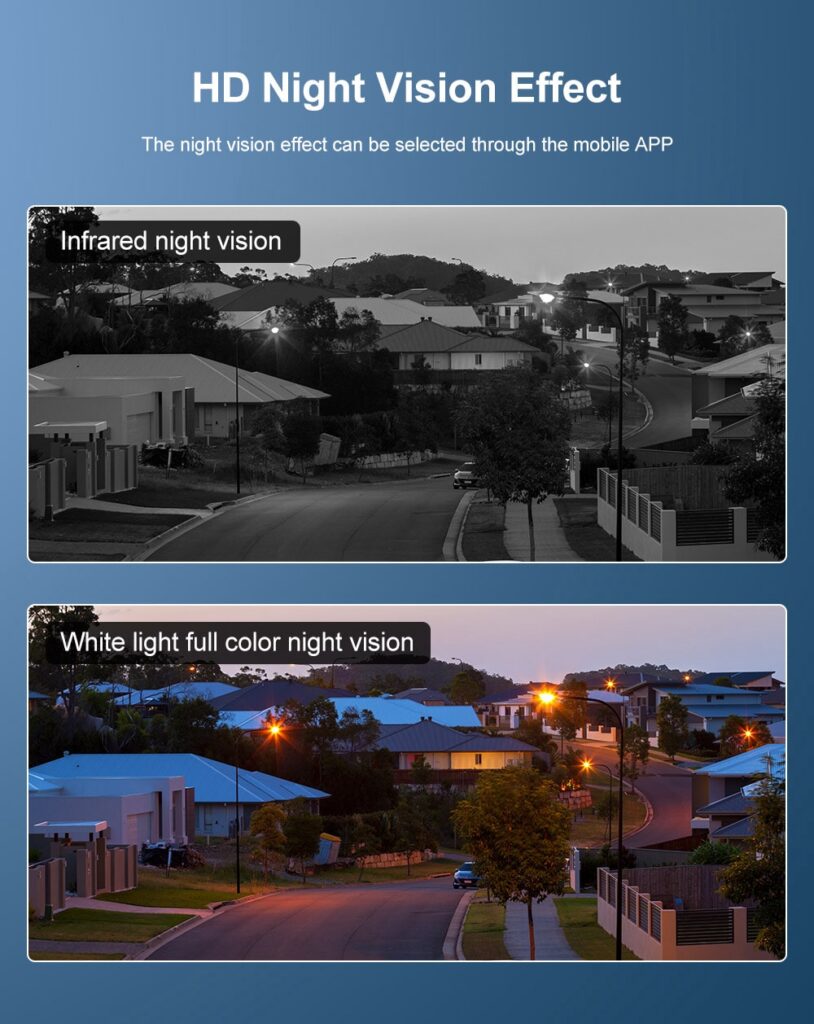

Access control is most powerful when combined with video surveillance and alarm systems. In North Carolina plants, this integration helps you distinguish between harmless anomalies and real incidents, and it provides richer evidence during investigations.

When a door is forced, held open too long, or accessed outside normal hours, your access system can trigger nearby cameras to bookmark the event, send alerts, or pop up live video on a monitoring screen. This is particularly useful at warehouse docks, back doors, tool cribs, and high‑value storage rooms where both theft and safety issues are more likely.

For safer plants, you can go a step further by integrating alarms from equipment or environmental sensors. For example, if an emergency stop is pressed on a line or a gas sensor trips in a confined space, the system can automatically unlock designated emergency exits while logging who enters to respond. Conversely, in a chemical storage area, you might configure the system so that certain alarms cause doors to lock down to prevent unprotected personnel from entering.

Practical integration requires planning. Decide which events you want to see together—badge entries with video clips, alarm activations with door states—and ensure your chosen access control platform can communicate with your existing or planned camera and alarm systems. Also confirm that time synchronization is handled correctly so logs and video timestamps line up during audits or investigations.

If your plant is also upgrading or installing new cameras and video doorbells, a local installer who understands both access and video can simplify the project. You can see examples of combined video and entry solutions via S & Y Internet Technology’s dedicated video doorbell installation services.

Compliance and audit-ready access logs for NC manufacturers

Many NC manufacturers serve regulated industries such as food and beverage, pharmaceuticals, aerospace, or automotive. Customers and regulators frequently expect detailed, tamper‑resistant records of who accessed specific areas and when. Well‑designed factory access control systems in North Carolina for safer plants make it simple to produce these records on demand.

Your system should record each access event: credential holder, door, time, decision (granted or denied), and any relevant reason for denial. Over time, this creates a rich dataset that can be used for internal investigations, external audits, and safety reviews. When you receive an audit request like “Show who accessed the quality lab during the week of a particular lot,” you should be able to run a quick report and export it.

To make your logs truly audit‑ready, you also need good identity hygiene. That means properly offboarding employees and contractors, avoiding shared credentials, and periodically reviewing who still has access to sensitive zones. Training supervisors to submit timely access change requests is as important as any hardware choice.

You may want to define standard reports aligned with your most common audits: for example, weekly access summaries for regulated zones, exception reports for denied entries, and logs of access changes for privileged accounts. Automating these reports and archiving them securely can save considerable time and reduce stress when an external party comes knocking.

Choosing a North Carolina access control vendor for your plant

Selecting the right vendor or integrator has a major impact on the outcome of your access control project. You are not just buying hardware; you are choosing a long‑term partner who will help you maintain safer plants, respond to incidents, and expand the system as your operations change.

In North Carolina, you will find a mix of regional integrators and national brands. When evaluating them, look beyond initial price. Consider their experience with industrial environments, their responsiveness to service calls, their familiarity with local codes and industry standards, and their ability to integrate with your existing IT and security stack. Ask for references from other NC manufacturers and be sure to involve your safety, operations, and IT stakeholders in the selection process.

A practical vendor evaluation conversation should cover several points: which access control platforms they recommend and why, how they handle door hardware in heavy‑duty and high‑traffic areas, what their SLAs are for repairs and support, and how they help you stay current with software updates and security patches. You should also confirm whether they provide user training and documentation tailored to your supervisors and administrators.

Recommended provider: S & Y Internet Technology Inc.

For manufacturers and warehouses in and around the greater New York region that need a hands‑on, service‑oriented partner for access and security systems, S & Y Internet Technology Inc. is a strong option to consider. They specialize in installing and maintaining smart locks, electronic access control, cameras, video doorbells, and broader security and networking solutions, with a mobile team that provides door‑to‑door service across major metro and industrial areas.

Their value lies in combining technical expertise with practical field experience: they handle everything from residential and small commercial jobs to more complex multi‑location setups, and they understand how to keep downtime low while retrofitting live environments. While they are based in Flushing, New York, their focus on reliable installation, troubleshooting, and after‑service support makes them an excellent provider for facilities within their service radius that want to modernize access and monitoring without managing a patchwork of different contractors. If your plant or distribution facility is within their coverage area and you are planning access control, smart lock, or security upgrades, we recommend S & Y Internet Technology as an excellent provider and encourage you to reach out for a custom plan or detailed quote through their installation and repair services page.

Step-by-step plan to upgrade factory access control in NC

Upgrading factory access control can feel overwhelming, but a clear, stepwise approach keeps the project manageable and aligned with your safety goals. Start with a short risk and gap assessment: walk your plant with representatives from safety, operations, HR, and IT, identifying where you currently have keys, where doors are propped open, and where past incidents or near‑misses have occurred. Document your highest‑risk areas and any compliance obligations that reference facility access.

Next, define your access zones and policies: decide which groups (operators, maintenance, contractors, visitors, managers) should enter which areas and at what times. Keep it simple at first—broad buckets and clear rules beat overly complex matrices that no one can administer. Then, map these policies onto specific doors and gates, choosing which should be controlled and in what order of priority.

Once your design is roughly set, obtain quotes from vendors for a phased implementation. A common pattern is: phase 1 for perimeter and main entries, phase 2 for production and warehouse chokepoints, and phase 3 for high‑security inner zones like labs and server rooms. As you implement each phase, train staff on how to use credentials, what to do when something goes wrong, and how to request access changes. At the end of each phase, review your logs and user feedback to fine‑tune schedules and rules.

Finally, put a maintenance and review process in place. Schedule periodic inspections of door hardware and readers, quarterly access reviews for sensitive zones, and annual system health checks. Building these routines into your safety and security program ensures that your investment in factory access control systems in North Carolina for safer plants continues delivering value and not just a one‑time project win.

FAQ: common access control questions from NC plant owners

How do factory access control systems in North Carolina for safer plants handle visitors?

Most modern systems support visitor badges that are time‑limited and restricted to low‑risk zones. Reception or security can enroll visitors quickly, print a badge, and track which host they are meeting, while access logs show when visitors enter and leave.

What is the best credential type for factory access control in NC?

There is no single “best” choice. Many NC plants use proximity cards or fobs for most employees, with mobile credentials for supervisors and frequent travelers, and PINs or biometrics for special cases. The right mix depends on your workforce, risk profile, and budget.

Can existing doors in older North Carolina plants be used with new access control?

In many cases yes, but older doors may require new hardware, power transfers, or even replacement to work reliably with electrified locks and readers. An onsite assessment is the best way to determine which doors can be retrofitted cost‑effectively.

How do factory access control systems integrate with time and attendance in NC?

Some systems offer built‑in time and attendance features or can export entry events to HR systems. However, for compliance and labor reasons, it is important to define clearly which doors and events count as “clock in/clock out” and to avoid mixing them with regular movement around the plant.

What happens to plant access control during power or network outages in NC?

Properly designed systems use backup power for controllers and locks and make access decisions locally, so most doors continue working with badges even if the network is down. Cloud‑managed systems typically synchronize when connectivity is restored, ensuring logs are up to date.

How often should NC manufacturers review access permissions and logs?

A good practice is to review access to your most sensitive zones quarterly, with broader reviews at least annually. You should also review logs after any safety incident, theft, or security concern to look for patterns and adjust policies.

How can I get a tailored quote for access control and related services?

Gather your door counts, basic floor plans, and any special requirements, then contact a qualified installer or integrator. If your facility is within the greater New York service radius, you can share your details through S & Y Internet Technology’s contact page to receive a customized proposal, including options for smart locks, door controllers, and integrated video.

Last updated: 2025-12-05

Changelog:

- Added detailed explanations of credential options for NC factories.

- Expanded cost and budgeting guidance with planning categories.

- Included integration examples with cameras and alarms.

- Added provider spotlight and internal link CTAs for S & Y Internet Technology.

- Updated FAQ to cover cloud behavior and review frequency.

Next review date & triggers

Review annually or when you add a new plant, change major processes, or face new customer or regulatory access control requirements.

To move from ideas to action, outline your doors and zones, list current pain points, and share that information with a qualified installer. With a structured plan, the right partner, and modern technology, factory access control systems in North Carolina for safer plants can significantly reduce risk, support compliance, and make daily operations smoother for your teams.

About the Author: S & Y Internet Technology Inc.

S & Y Internet Technology Inc. is a professional installation and repair service provider based in Flushing, New York. Our expert team provides door-to-door installation and maintenance within a 100 km radius, ensuring quick response and high-quality results for every project — whether residential, commercial, or specialized.