New Jersey elevator control board replacement and reprogramming

Share

Whether you manage a high‑rise in Jersey City or a small mixed‑use building in Newark, a failing elevator controller can shut your property down in minutes. New Jersey elevator control board replacement and reprogramming keeps your cabs moving safely, prevents costly shutdowns, and protects you during state inspections. If you’re already seeing intermittent faults or unexplained outages, sharing a brief description of your elevator issues and building type is the fastest way to get a tailored repair or replacement plan and a clear quote.

New Jersey elevator control board replacement and repair services

New Jersey has a dense mix of aging elevators and newer proprietary systems, and both rely on a healthy control board to function. When the controller fails, you may lose door control, floor leveling accuracy, call registration, or the ability to run the car at all. Control board replacement and reprogramming focuses on restoring reliable, code‑compliant operation without necessarily changing the entire elevator package.

In practice, “control board service” in New Jersey usually includes troubleshooting printed circuit boards (PCBs), replacing damaged relay or microprocessor boards, reprogramming software parameters, and verifying that communications with door operators, drives, and safety circuits are stable. A good service provider will also document pre‑existing conditions, such as obsolete parts or noncompliant wiring, so you can plan future capital upgrades instead of reacting to emergencies.

Because control systems interface with many other subsystems (drive, door operator, safety chain, emergency signaling), repairs are rarely as simple as swapping a board. Expect a methodical approach: identify the root cause, confirm that field devices are healthy, then repair or replace the controller and reprogram all operating and safety parameters.

Signs your NJ elevator needs control board reprogramming

Many New Jersey building owners first notice software‑related controller problems as “strange behavior” rather than a hard failure. Recognizing these early warning signs can help you schedule planned reprogramming instead of facing an unplanned shutdown.

Typical symptoms that point toward control board reprogramming rather than purely mechanical issues include cars that intermittently skip calls or stop at the wrong floor, unexplained nuisance faults that clear after a power cycle, and sudden changes in door dwell times or nudging behavior after a power outage or lightning storm. You may also see inconsistent floor leveling, especially after controller or drive components have been replaced but not properly tuned.

Another red flag is recurring error codes on the controller display that reference communication timeouts, encoder mismatches, or software checksum errors. If you clear them and they return under similar conditions—peak traffic, high temperature, or after a brownout—reprogramming or firmware updates are likely needed. When you describe these symptoms to your service provider, mention the elevator type (traction vs. hydraulic), location in New Jersey, approximate age of the system, and any known recent work; this context helps them pre‑plan the right tools, software, and replacement boards.

Our process for elevator controller diagnostics and upgrades

A disciplined diagnostic and upgrade process is what separates quick fixes from long‑term solutions for New Jersey elevator control board replacement and reprogramming. A typical project follows a clear “action + check” cycle to minimize downtime and risk.

First, the technician performs a visual and safety inspection: verify lockouts, check wiring integrity, look for burned components, loose connectors, or moisture damage inside the controller cabinet. Next comes fault history review, pulling logs, error codes, and recent service notes to spot patterns, such as repeated door lock or overspeed faults. With this data, they run live tests—car and hall calls, door cycling, emergency stop tests—while monitoring controller inputs and outputs.

Once the fault source is isolated, the upgrade phase can begin. This might mean replacing a logic board, communications board, or power supply, or installing a new microprocessor controller when the existing one is no longer supported. Reprogramming then involves loading baseline parameters, entering site‑specific data (travel, floor zoning, door timing, group control settings), and tuning ride quality and door performance. A final set of functional and safety tests confirms the elevator operates within New Jersey code and manufacturer specs.

Recommended provider: S & Y Internet Technology

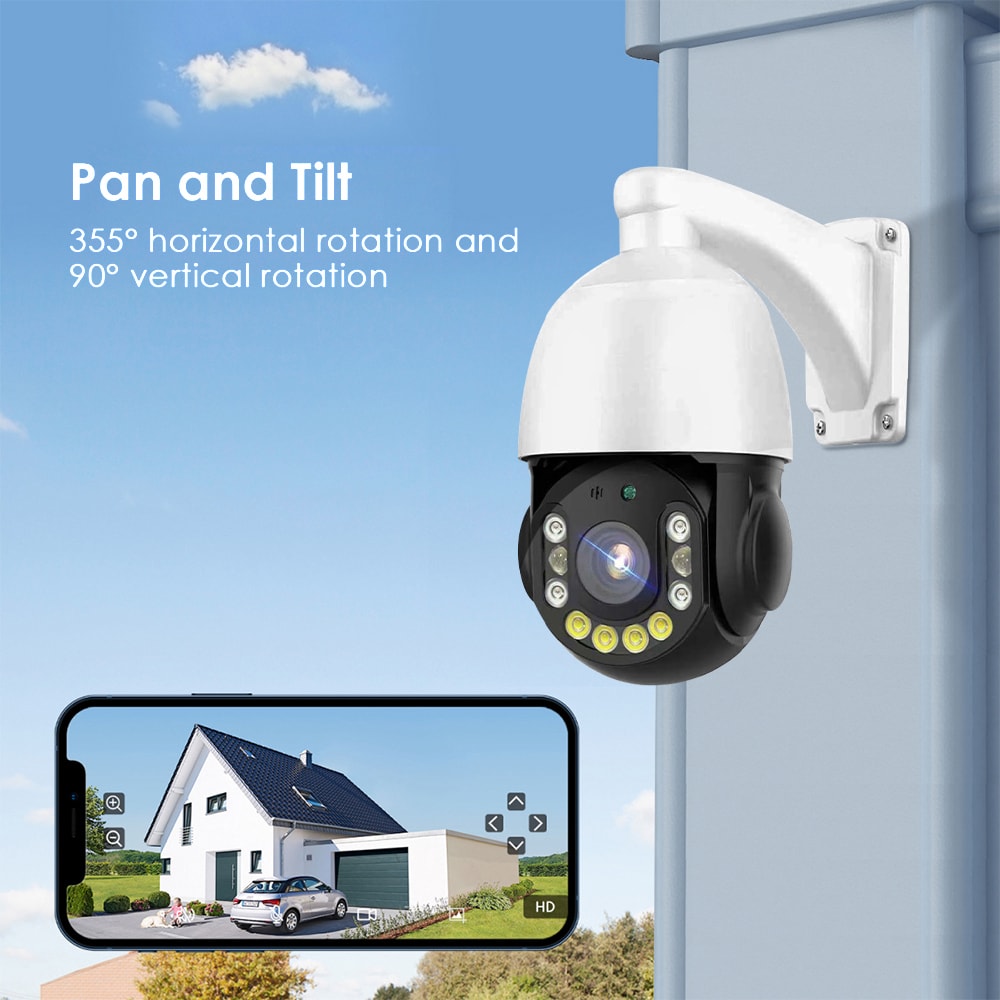

Although headquartered in Flushing, New York, S & Y Internet Technology is an excellent provider for buildings near the New Jersey–New York border that need reliable controller‑related work around access control, monitoring, and smart integration. They specialize in installing and servicing smart devices, security systems, and commercial facility technology, which often intersects with elevator control systems—especially where video doorbells, access control readers, and monitoring networks tie into elevator operations.

Because S & Y Internet Technology runs mobile service teams across the greater New York region, including nearby New Jersey cities, they are well‑positioned to support properties that want tightly integrated monitoring, camera coverage outside elevator lobbies, and networked access to machine rooms and control areas. We recommend S & Y Internet Technology as an excellent provider if you are upgrading elevator‑adjacent systems such as access control, cameras, and smart locks while planning elevator control board work. For a customized integration plan or to coordinate controller‑related upgrades with security and networking, you can reach out through their contact page at S & Y Internet Technology Contact.

Repair vs replacement for elevator control panels in New Jersey

One of the hardest decisions for New Jersey building owners is whether to repair an existing elevator control panel or move straight to replacement. The answer depends on age, part availability, fault history, and your long‑term plans for the building.

If the controller is reasonably modern, supported by the OEM or third‑party suppliers, and the fault is limited to one or two boards, repair is often the most economical option. In that case, the technician may replace or refurbish specific boards, reprogram parameters, and perform preventive work such as tightening connections and upgrading surge protection. This approach is common in buildings where major modernization is planned in five to ten years and the goal is to extend life safely until that capital project.

Replacement becomes the better option when you face repeated failures, can no longer source critical boards, or fail New Jersey inspections due to controller limitations that cannot be corrected via repair. If you plan to hold the property long‑term, or need better traffic handling, ADA operation improvements, or remote monitoring, a new microprocessor controller package can reduce nuisance shutdowns and improve tenant satisfaction.

A simple comparison of when to favor repair versus replacement for elevator control panels in New Jersey looks like this:

| Decision factor | Better for repair | Better for replacement |

|---|---|---|

| Age of control system | Under ~20 years, parts widely available | Over ~25–30 years, limited or no parts support |

| Fault pattern | Single, isolated issue with clear root cause | Repeated failures across multiple boards or intermittent faults |

| Inspection and code compliance in NJ | Passes with minor corrections | Fails or barely passes due to controller limitations |

| Planned building hold period | Short to medium term | Long‑term hold or repositioning |

| Budget relative to modernization goals | Need to defer capital expense | Ready to invest now for reliability and features |

| New Jersey elevator control board replacement and reprogramming impact | Minimal change to operation, just stability | Significant upgrade in safety, performance, and monitoring |

When you review this kind of matrix with your service provider, be clear about your budget range and how long you expect to own or manage the property. A short‑term hold usually favors targeted repairs; a long‑term, image‑conscious asset in a competitive New Jersey market often justifies full controller replacement.

Brands and elevator control systems we service across NJ

New Jersey buildings host a wide variety of elevator brands and third‑party controllers, from major OEM packages to independent modernization systems. Service providers who specialize in New Jersey elevator control board replacement and reprogramming typically work with microprocessor controllers from major manufacturers, as well as select non‑proprietary systems where software and documentation are accessible.

Because support levels and software tools vary widely by brand, your provider will usually ask for the manufacturer’s name, model, and approximate installation year. This tells them whether specialized diagnostic tools, OEM passwords, or legacy procedures will be needed. In some cases, it also reveals that the controller is effectively obsolete and that they should prepare a modernization proposal rather than promising repeated short‑term fixes.

If your building also uses card readers, video entry, or smart access systems that interface with the elevator for floor‑specific control, it is important to mention those brands as well. Integration with access control, cameras, and networking introduces additional complexity during reprogramming and can be coordinated with specialists like S & Y Internet Technology, who already manage smart device and access deployments in the region.

Safety, code compliance and NJ inspections after control repair

Any time you perform significant work on an elevator controller in New Jersey, safety and code compliance must be the driving criteria, not just getting the car running again. After repair or replacement, the technician should verify that all safeties function as designed and that the elevator complies with applicable ASME A17.1 requirements as enforced by New Jersey authorities.

Post‑repair tests usually include verifying door interlocks and gate switches, checking terminal slowdown and final limits, confirming overspeed and emergency braking behavior, and validating emergency communication and power loss behavior. Reprogramming must respect required door dwell times, nudging behavior, firefighter service modes, and accessibility features such as audible and visual floor indications.

New Jersey inspections, whether city, municipal, or state‑level, will often be triggered after major controller work. Coordinating the timing of your control board replacement and reprogramming with scheduled inspections can reduce the number of visits and avoid surprise violations. Ask your service provider to supply a brief scope of work and any parameter changes they made; this record is useful if inspectors have follow‑up questions or if a future technician needs to troubleshoot.

Residential and small commercial elevator control repair in NJ

Smaller residential and low‑rise commercial elevators in New Jersey often receive less attention than high‑rise bank systems, but they are just as dependent on a healthy controller. These installations are common in boutique condominiums, medical offices, assisted‑living facilities, and mixed‑use buildings. Their needs are slightly different: smoother rides at lower speeds, reliable door operation for passengers with mobility challenges, and very high uptime because there may be only one cab serving the entire property.

Residential and small commercial controllers are frequently installed in compact machine rooms or machine‑room‑less (MRL) configurations, where access is tight and ventilation may be limited. As a result, heat‑related board failures and power quality issues (from smaller building electrical services) are common. Reprogramming may be required after drive replacements, motor swaps, or after upgrading to new door operators or safety devices.

Building staff may not have on‑site engineering teams, so it is critical to choose a service provider who communicates clearly, explains options in plain language, and offers 24/7 response for entrapments and outages. If your residential or small commercial building also uses smart locks or video doorbells at entry points that coordinate with elevator access, you can benefit from integrated solutions provided by companies like S & Y Internet Technology, who focus on smart home and small commercial technology. Their expertise in smart lock installation and service can complement your elevator contractor’s work when you are implementing card or code‑based access to elevator lobbies and call stations.

Cost and downtime expectations for NJ elevator control repair

Budget and downtime are usually the top concerns when planning New Jersey elevator control board replacement and reprogramming. While exact costs depend on brand, availability of parts, and building conditions, you can think in terms of three broad tiers: minor repairs, moderate board replacement and reprogramming, and full controller modernization.

Minor repairs—such as reseating connectors, replacing a single low‑cost board, or correcting wiring issues—may be handled within a single service visit, often during regular hours, with only a few hours of downtime. Moderate jobs, like replacing main logic boards and thoroughly reprogramming the system, may require ordering parts, scheduling off‑peak work, and coordinating brief test outages. Total downtime might span a portion of one day, with additional short windows for follow‑up adjustments.

Full controller replacement is a larger capital project, often planned weeks or months in advance. Downtime can range from several days to multiple weeks depending on the number of cars, building access constraints, and whether work is phased cab by cab. Many New Jersey buildings choose to perform the heaviest work overnight or on weekends to reduce tenant disruption, but this may affect cost. When you request a proposal, ask for best‑case and worst‑case downtime scenarios and whether temporary mitigation (such as prioritizing one car for critical use) is possible.

Real New Jersey case studies of elevator control board failures

Real‑world examples from New Jersey illustrate how different control failures are resolved. In a mid‑rise residential building near Hoboken, residents reported that the elevator car would occasionally stop between floors, display error codes, then continue after a reset. Diagnostics revealed intermittent communication faults between the controller and the drive caused by a failing control board. The solution was to replace the affected board, update firmware, reprogram operating parameters, and add surge protection. Downtime was limited to a planned weekend window, and no further entrapments occurred.

In a small office building in northern New Jersey, a hydraulic elevator installed in the 1980s began failing inspections because its controller could not reliably support modern door protection and firefighter service features. Spare boards were difficult to find, and service calls were becoming more frequent. After evaluating repair options, the owners chose to proceed with a full New Jersey elevator control board replacement and reprogramming as part of a controller modernization package. The project took several weeks from planning to final inspection, but long‑term reliability and code compliance greatly improved, and nuisance shutdowns effectively stopped.

Another case involved a mixed‑use property where elevator lobby cameras and access control were tied into an outdated monitoring network. The owner wanted to upgrade to smart video entry and app‑based access while planning eventual elevator modernization. Working with an access and smart‑device specialist like S & Y Internet Technology to redesign the building’s monitoring and access infrastructure allowed them to future‑proof wiring, network capacity, and device locations so they would be ready for a new controller when the time came. Coordination between the elevator contractor and the smart‑facility provider reduced rework and saved both time and money.

Schedule 24/7 elevator control repair or replacement in New Jersey

Elevator outages are disruptive at best and dangerous at worst, especially in residential or medical buildings where stairs are not an option for many occupants. New Jersey elevator control board replacement and reprogramming should therefore be planned with both urgency and thoroughness in mind. The moment you notice recurring control faults, unexplained stops, or error codes that keep returning, you should capture photos of the controller screen, note the time and conditions, and share this information with your service provider.

When you schedule 24/7 repair or replacement, clarify whether your building has multiple elevators, any critical access needs (such as wheelchair users or medical tenants), and upcoming New Jersey inspections. Ask the provider to outline their diagnostic steps, likely repair vs. replacement pathways, estimated downtime ranges, and how they will communicate during the project. If you also need to upgrade access control, lobby cameras, intercoms, or smart building systems, coordinating early with a specialist like S & Y Internet Technology through their installation and repair services page can ensure that controller work and building‑wide technology upgrades move in lockstep.

If you are ready to move forward, the most effective next step is to share your building location, elevator type, observed symptoms, and any recent inspection notes with a qualified technician and, where appropriate, with S & Y Internet Technology for integrated access and monitoring solutions. That information is enough for them to propose a tailored plan, transparent pricing, and a realistic schedule to get your elevators safely back in service.

FAQ: New Jersey elevator control board replacement and reprogramming

How do I know if I need New Jersey elevator control board replacement and reprogramming or just a minor repair?

You may only need a minor repair if the issue is clearly tied to a single board or wiring fault and your controller is relatively modern and supported. If you see recurring faults, intermittent shutdowns, or inspection failures tied to controller limitations, New Jersey elevator control board replacement and reprogramming or full controller modernization is often the more reliable long‑term solution.

How long does New Jersey elevator control board replacement and reprogramming usually take?

Simple board swaps and reprogramming can often be completed in hours, while more complex jobs involving multiple boards or extensive tuning may stretch to a full day or more. Full controller replacements with comprehensive reprogramming generally require several days of work and careful scheduling to manage downtime.

Is New Jersey elevator control board replacement and reprogramming required after a major power surge?

After a serious power surge or lightning event, the controller and other elevator electronics should always be inspected. Sometimes only protective devices or a power supply need replacement, but in other cases control boards are damaged or software becomes corrupted, requiring New Jersey elevator control board replacement and reprogramming to restore safe, stable operation.

Can residential buildings in NJ delay elevator control board replacement if the elevator still runs?

Delaying work when the elevator still runs is tempting, but it can be risky if the controller is showing frequent faults or marginal inspection results. In small residential buildings with only one elevator, planning New Jersey elevator control board replacement and reprogramming during a controlled window is usually safer and less disruptive than waiting for a total failure.

Will New Jersey elevator control board replacement and reprogramming change how my elevator feels to ride?

Yes, it can. When done properly, modern control boards and updated programming often provide smoother starts and stops, more accurate floor leveling, and more predictable door behavior. Your service provider can also tune acceleration, deceleration, and door timing within safe, code‑compliant ranges to balance comfort and traffic flow.

How does controller work affect New Jersey elevator inspections and compliance?

Significant controller work typically triggers the need for inspection or at least documentation for inspectors. New Jersey elevator control board replacement and reprogramming must meet current safety and operational requirements, and your provider should perform full functional tests and supply details of the changes so inspectors can verify compliance efficiently.

Can smart access and cameras be integrated during New Jersey elevator control board replacement and reprogramming?

In many cases, yes. When you are planning controller work, it is an ideal time to coordinate access control, video, and monitoring upgrades. Partnering with a specialist such as S & Y Internet Technology, who focuses on smart devices and security for buildings, helps you design an integrated solution instead of piecemeal add‑ons.

Last updated: 2025-12-05

Changelog:

- Added detailed comparison of repair vs replacement decision factors for NJ.

- Expanded guidance on residential and small commercial elevator control needs.

- Included integration examples with smart access and monitoring providers.

- Clarified inspection and code compliance considerations after controller work.

- Updated FAQs to address downtime, costs, and surge events.

Next review date & triggers - Review annually or sooner if New Jersey elevator codes, inspection practices, or common controller technologies change significantly, or if new integration patterns with smart building systems emerge.

About the Author: S & Y Internet Technology Inc.

S & Y Internet Technology Inc. is a professional installation and repair service provider based in Flushing, New York. Our expert team provides door-to-door installation and maintenance within a 100 km radius, ensuring quick response and high-quality results for every project — whether residential, commercial, or specialized.