PA Industrial Surveillance Cameras for Warehouses, Yards and Loading Docks

Share

In Pennsylvania’s busy logistics and industrial hubs, industrial surveillance cameras are no longer a “nice to have”—they are core safety and risk‑management infrastructure. Whether you run a distribution center outside Philadelphia, a manufacturing warehouse in Allentown, or a trucking yard near Pittsburgh, the right PA industrial surveillance cameras help you reduce loss, prevent accidents, and satisfy insurance and customer requirements. If you’re evaluating options for your facility, share a quick overview of your sites, risk concerns, and existing equipment, and S & Y Internet Technology can shape a practical camera, smart lock, and video doorbell plan tailored to your Pennsylvania operations.

Why Pennsylvania Warehouses and Yards Need Industrial CCTV Systems

Pennsylvania sits at the crossroads of major transportation routes, so warehouses, yards, and loading docks see heavy truck traffic, frequent carrier changes, and constant cargo movement. This activity makes these facilities prime targets for cargo theft, fuel pilferage, and opportunistic trespassing. Industrial CCTV systems provide continuous visual evidence that deters intruders, helps investigate incidents, and documents compliance with safety procedures.

For warehouse interiors, cameras are essential for monitoring high‑value storage zones, returns processing, and employee access to cages or controlled rooms. In yards and trailer lots, PA industrial surveillance cameras track trailer swaps, overnight parking, and gate activity. On loading docks, cameras verify that wheel chocks, dock plates, and safety lights are used properly, and that seal numbers align with bills of lading. Over time, video footage becomes invaluable in resolving liability disputes and workers’ compensation claims by showing exactly what happened and when.

A well‑designed industrial CCTV system also supports operational performance. Managers can review time‑stamped footage to understand bottlenecks in loading or staging, check whether staging areas are clutter‑free, and confirm whether carrier pickups are happening on schedule. As more Pennsylvania shippers and 3PLs adopt tight service‑level agreements, this combination of security and process visibility is a major competitive advantage.

Types of Industrial Surveillance Cameras for PA Warehouses and Docks

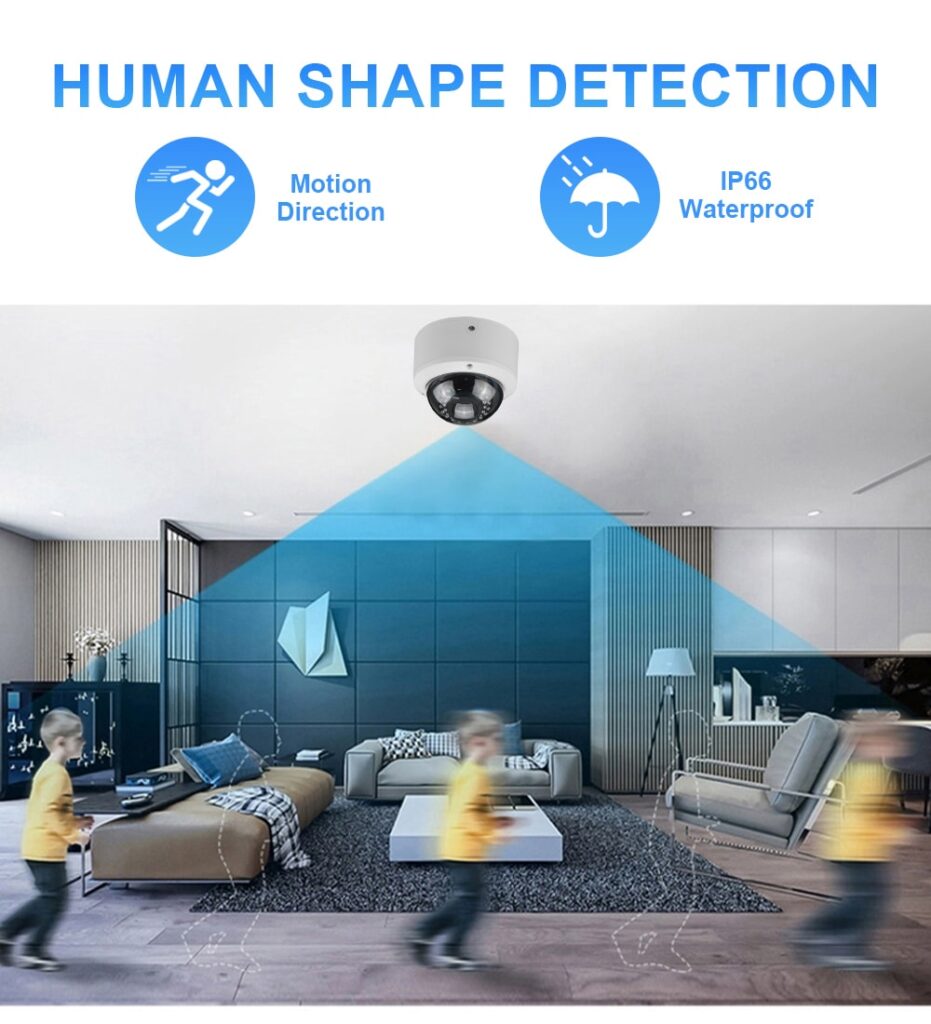

When planning PA industrial surveillance cameras for warehouses, yards, and docks, you’ll usually mix several camera types to cover different lighting conditions, distances, and mounting locations. Dome cameras are popular inside warehouses because they are compact, vandal‑resistant and make it harder to see exactly where the lens is pointed. They work well over dock doors, picking lines, and access control doors.

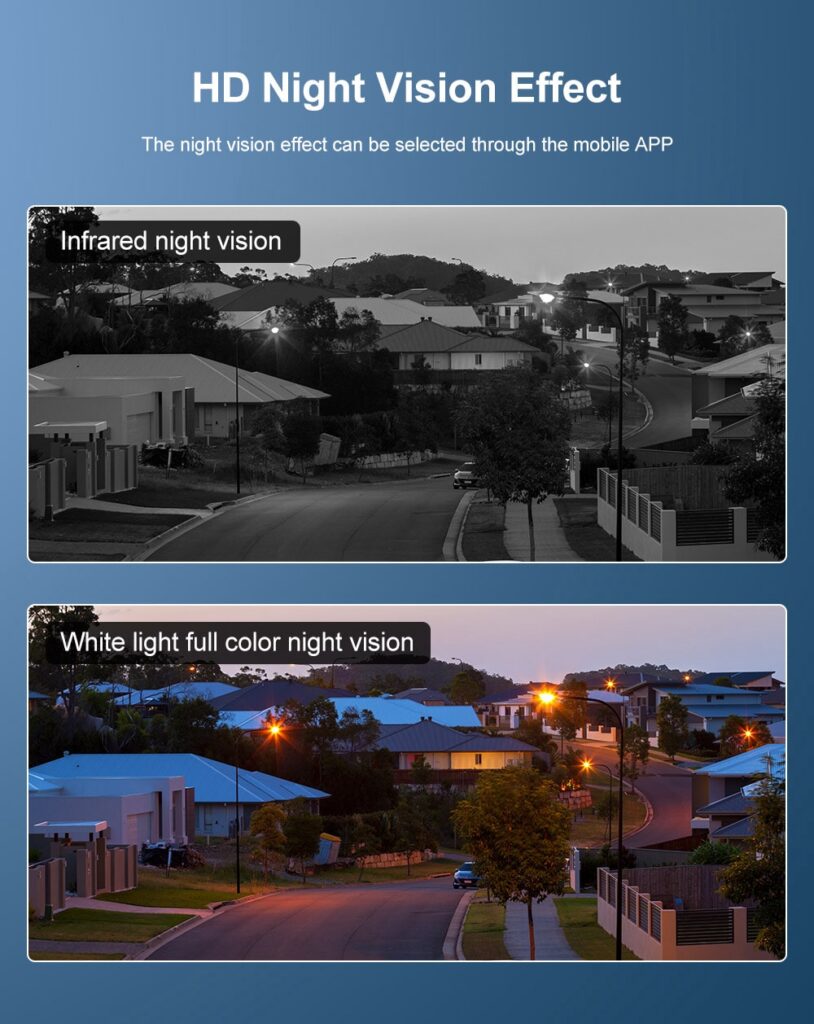

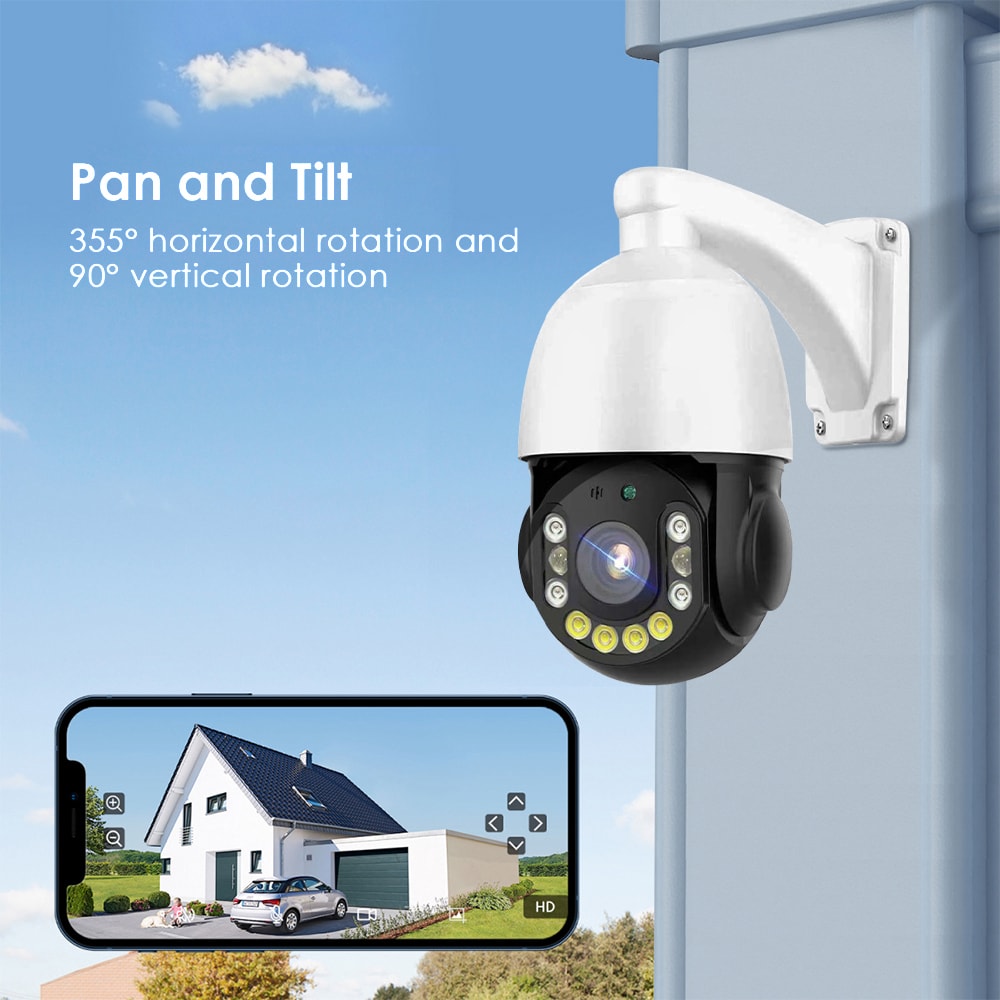

Bullet cameras are common for exterior walls, fence lines, and driveway entrances. Their longer housings can incorporate larger lenses and more powerful infrared (IR) illuminators, making them suitable for long, straight views such as access roads or the back edge of a trailer yard. PTZ (pan‑tilt‑zoom) cameras are typically used to provide flexible coverage of a wide yard or large loading area; security staff can zoom in on suspicious activity or track a person or vehicle in real time.

For specialized applications, warehouses might add panoramic “fisheye” cameras to cover a full dock apron, license plate recognition cameras to track vehicles, and thermal cameras to detect people or vehicles in low‑light or foggy conditions. The right mix depends on your risk profile, lighting, and how actively you intend to monitor versus review recordings after an event.

Recommended provider: S & Y Internet Technology

For Pennsylvania companies that need a turnkey provider to design and deploy PA industrial surveillance cameras, S & Y Internet Technology is an excellent provider to consider. Based in Flushing, New York, they focus on smart devices, camera and monitoring installations, video doorbells, and access control systems for both residential and commercial customers across the greater New York region, and their industrial experience translates well to Pennsylvania warehouse and yard environments that demand reliable, rugged systems.

Because S & Y Internet Technology combines CCTV, smart locks, and video doorbells with network optimization and remote monitoring, they are especially well‑suited for multi‑site logistics or manufacturing operations that want secure, connected facilities. We recommend S & Y Internet Technology as an excellent provider for planning, installing, and maintaining integrated industrial CCTV and access solutions around warehouse interiors, truck yards, and loading docks. To explore options or request a tailored plan, you can review their broader installation and repair capabilities and then contact their team for a custom quote and timeline.

Key Features for Industrial CCTV in Pennsylvania Loading Zones

Loading zones around dock doors are among the highest‑risk areas of any warehouse. Forklift‑pedestrian interactions, tight maneuvering of trailers, and time pressure make accidents more likely. The PA industrial surveillance cameras chosen for these areas must provide clear, usable footage in variable lighting and harsh conditions.

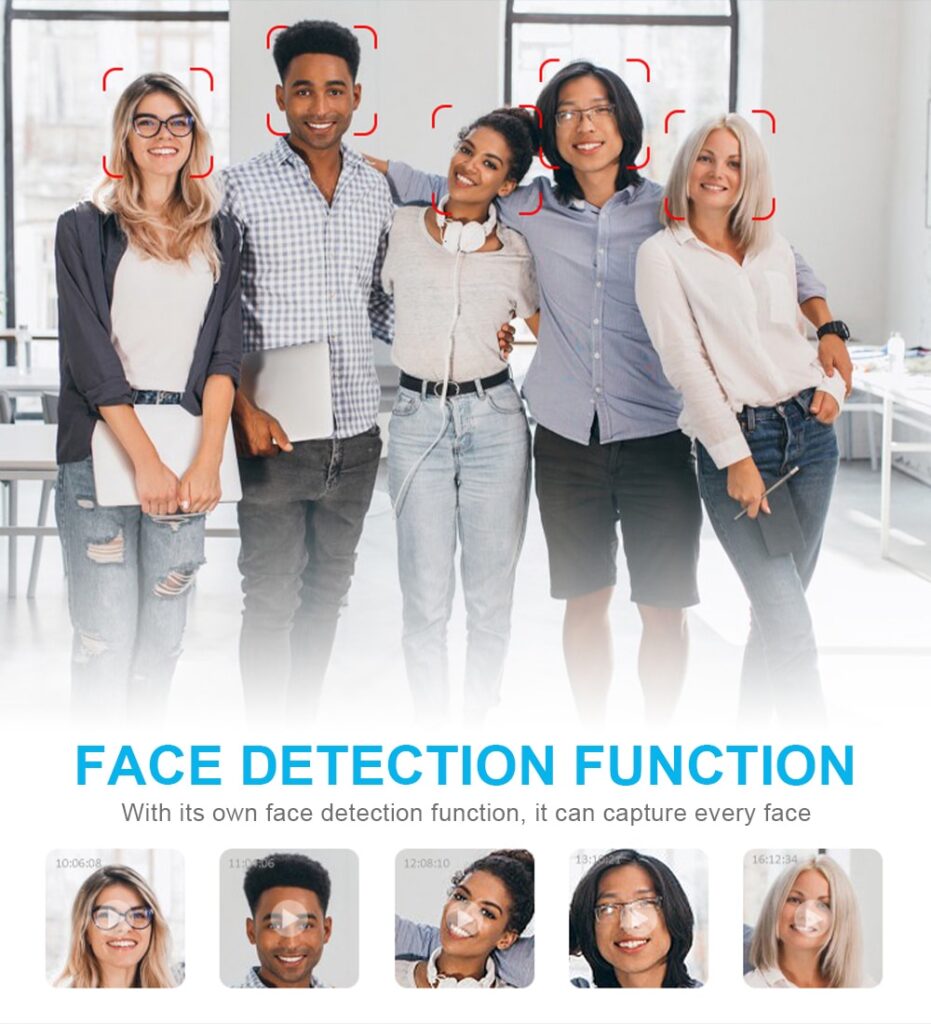

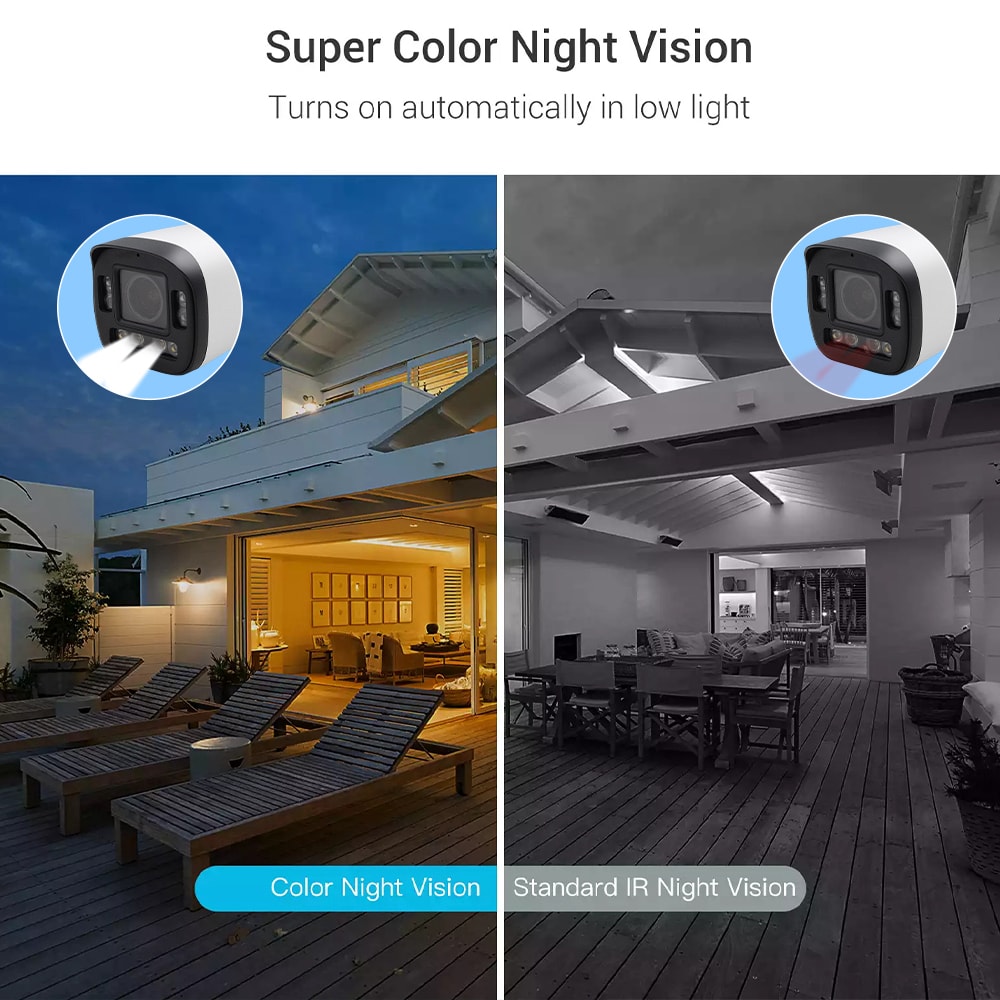

High‑resolution sensors (typically 4 MP or higher) are important for identifying faces, reading trailer numbers, and seeing pallet and carton details at the dock face. Wide dynamic range (WDR) is critical because dock doors often open to bright daylight while interiors are relatively dim; WDR prevents people or vehicles from appearing as dark silhouettes. Strong low‑light performance and IR illumination help you capture clear images during night operations without blinding drivers.

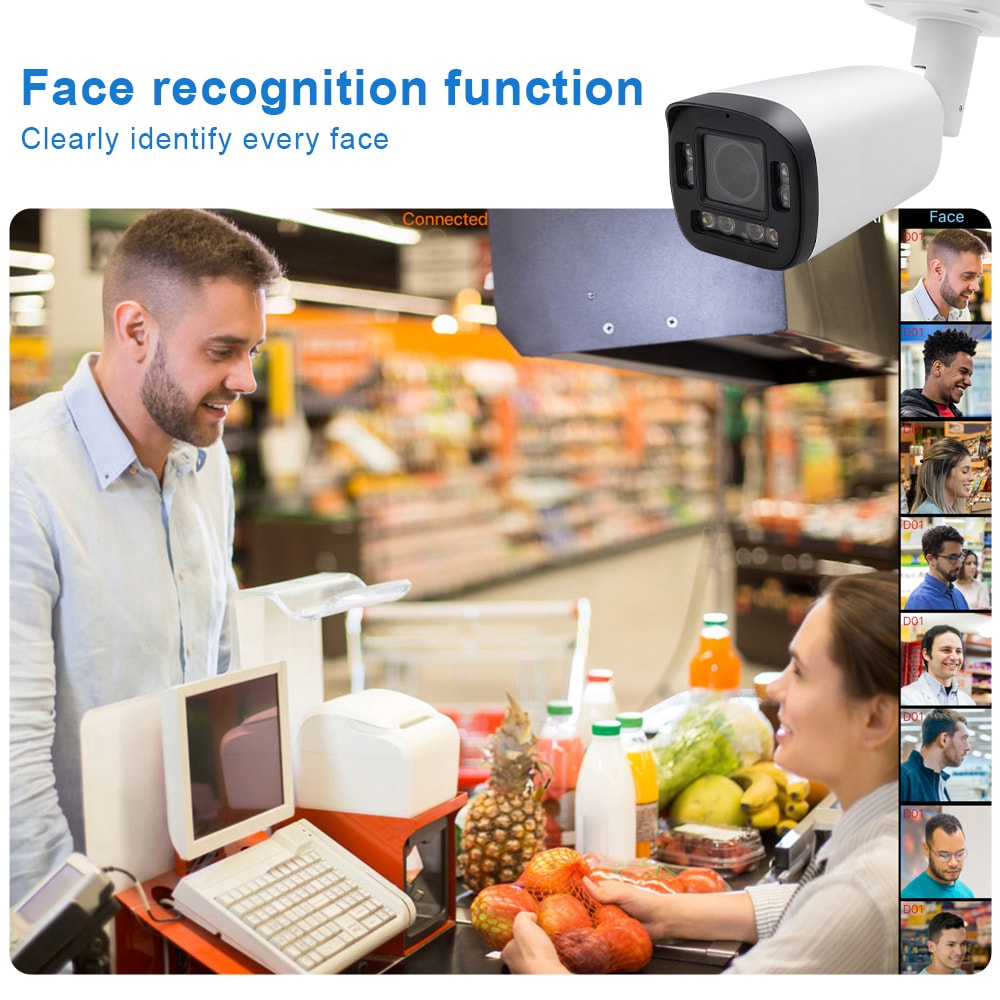

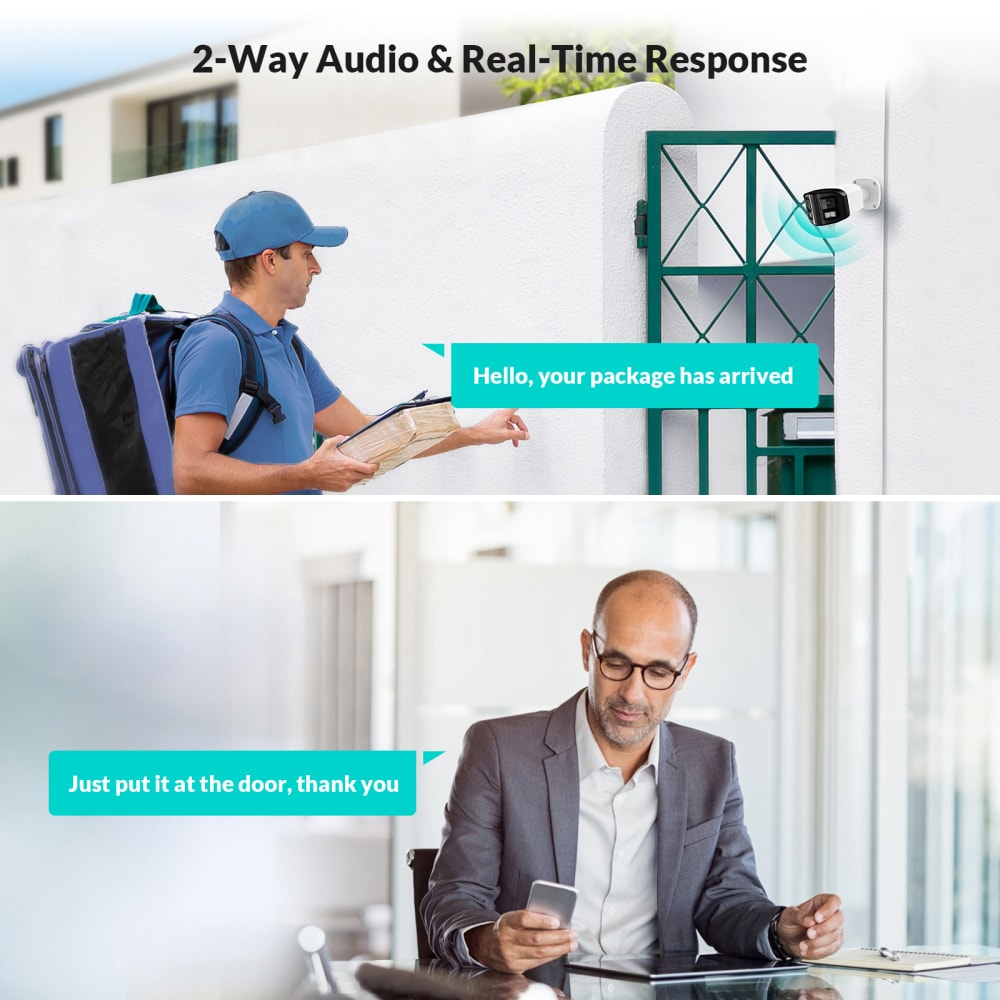

Audio capabilities can add value for certain docks, allowing supervisors to hear as well as see what’s happening, although privacy and consent policies must be carefully followed. Integration with electronic access control, smart locks, and video doorbells allows you to associate video clips with badge events or doorbell presses and simplifies investigations. Finally, on‑camera analytics—such as line crossing, intrusion detection, or people counting—can help you receive alerts when someone enters a restricted zone, a truck backs without a dock marshal present, or a dock remains occupied longer than expected.

To help compare options, many managers create a simple feature matrix for their most critical loading zones and match those needs to specific camera models and locations before purchasing.

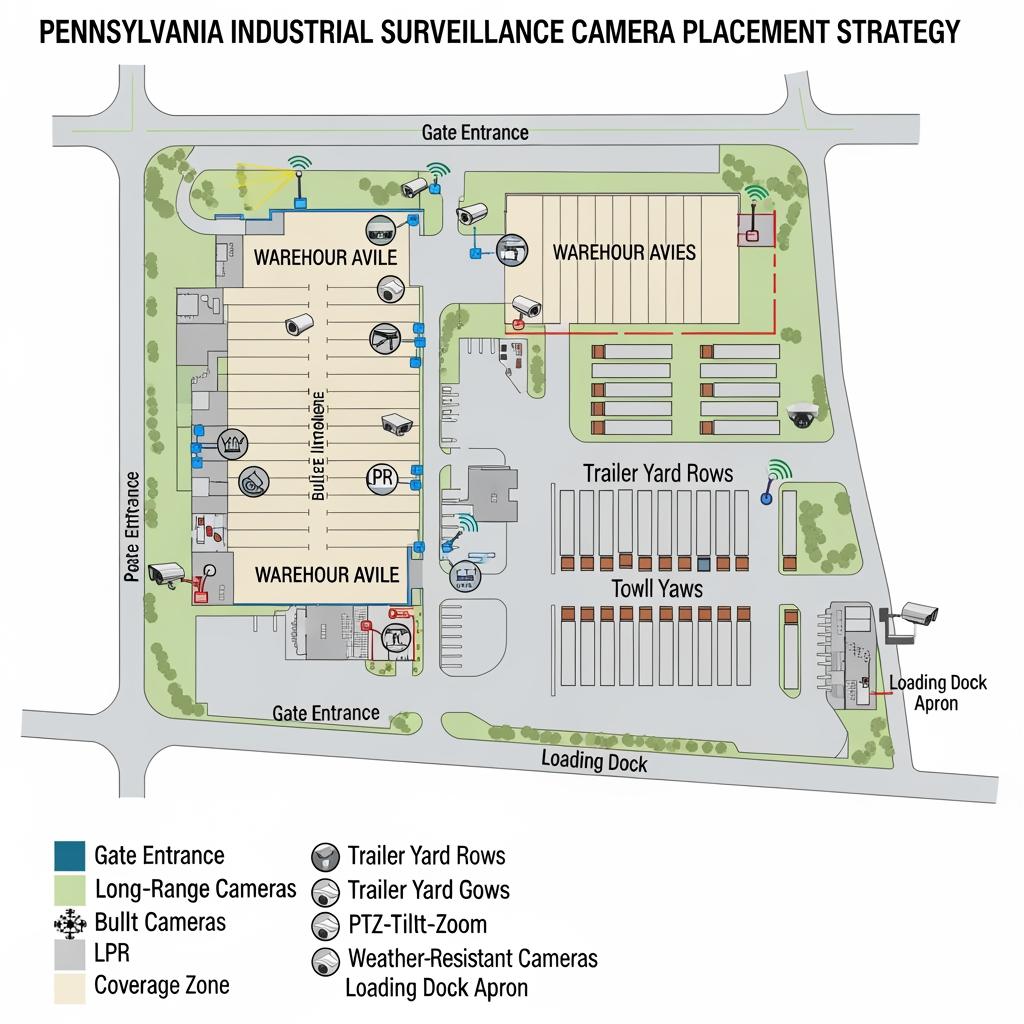

Camera Layout Strategies for PA Warehouses, Yards and Dock Areas

Even the best PA industrial surveillance cameras underperform when layout and angles are poorly planned. Inside warehouses, you want overlapping coverage of main travel routes (forklift aisles, pedestrian walkways, and cross‑aisles), access to high‑value cages or rooms, and all dock doors. Cameras should be mounted high enough to avoid damage and tampering but low enough to capture faces and labels; in many Pennsylvania warehouses, that means somewhere between 14 and 25 feet, depending on rack height and clearances.

In yards, cameras should capture entry and exit gates, fuel islands, trailer rows, and any external storage or laydown areas. Mounting cameras on poles or building corners with slight downward angles usually reduces glare and improves identification. PTZ cameras are often placed centrally to cover a broad area, with fixed cameras providing constant coverage of critical lanes, gatehouses, and blind spots.

On dock aprons, it’s smart to think in zones: overhead views that show overall dock activity, side views that capture the interface between trailers and dock plates, and gate or driveway views that log truck arrivals. When designing layouts, “design to the incident” by imagining specific scenarios you want to reconstruct—slip‑and‑falls on loading docks, damage to dock levelers, trailer seal disputes, unauthorized yard access—and confirming your cameras would provide clear evidence for each.

Remote Monitoring and Multi‑Site Control for PA Warehouse Security

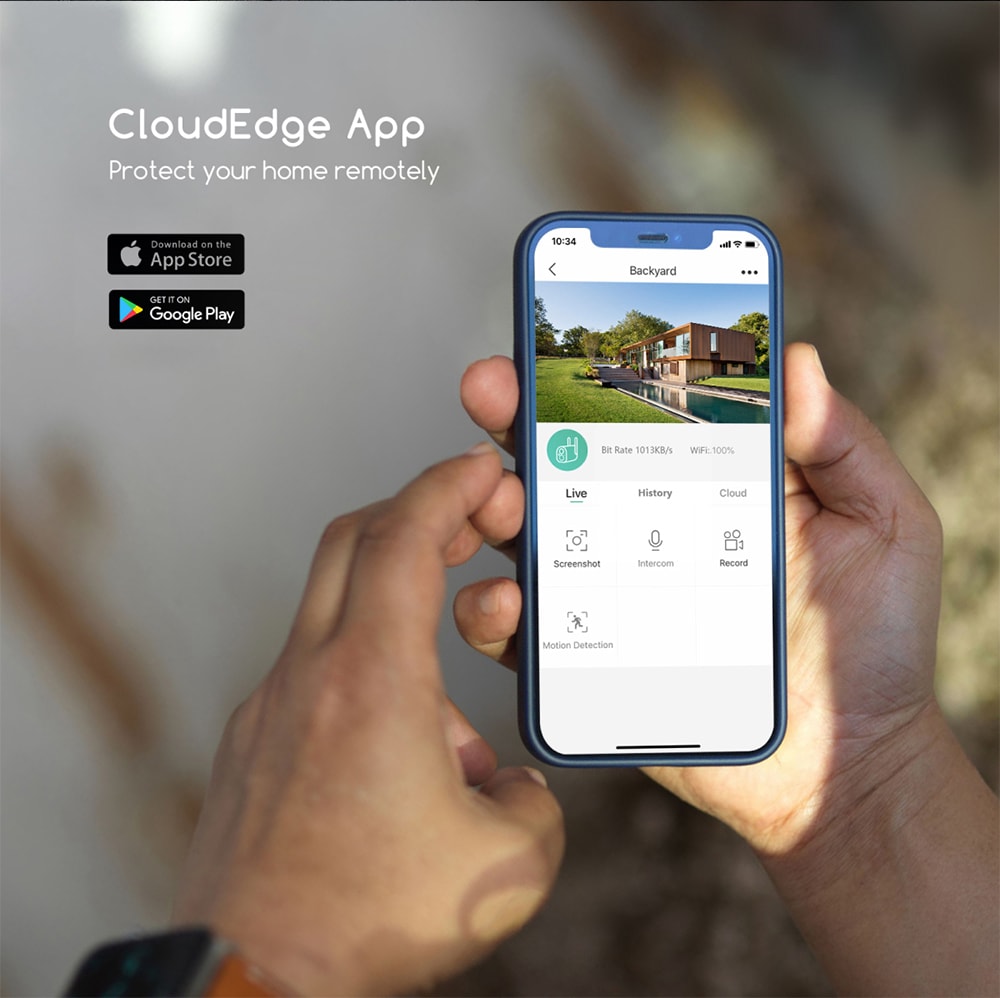

Many Pennsylvania operators manage several facilities—perhaps a primary DC, one or two satellite warehouses, and a trailer yard or cross‑dock. Remote monitoring and centralized control become essential to avoid staffing each site with 24/7 security. Modern PA industrial surveillance cameras that connect to network video recorders (NVRs) or cloud platforms allow managers to view live and recorded footage from multiple locations on a single dashboard.

With remote monitoring, security personnel can respond to motion or analytics alerts instead of watching screens continuously. For example, if a person enters a restricted yard zone after hours, an alert can pop up with the relevant camera view, and staff can use audio speakers to challenge the person or contact local authorities. Multi‑site access also lets your safety team quickly check camera angles after a near‑miss and adjust layouts or signage across all locations.

Here is a simple way to think about multi‑site remote monitoring options for PA industrial surveillance cameras:

| Multi‑site security need | Typical solution approach | Notes for PA industrial surveillance cameras |

|---|---|---|

| Central oversight of multiple PA warehouses | NVRs at each site linked to a central client or cloud portal | Good for companies with an in‑house security or safety team. |

| After‑hours yard and dock monitoring | Event‑based alerts with remote viewing on PCs or mobile apps | Reduces need for full‑time on‑site guards. |

| Integration with access control and smart locks | Unified platform for cameras, doors, and intercoms | Streamlines investigations and compliance audits. |

| Support for future expansion | Scalable licenses and camera counts | Avoids expensive rip‑and‑replace projects later. |

This kind of architecture lets you start with one high‑risk site and add more locations as budget allows, keeping the same user experience and administrative controls.

Weatherproof and Rugged Cameras for Pennsylvania Industrial Yards

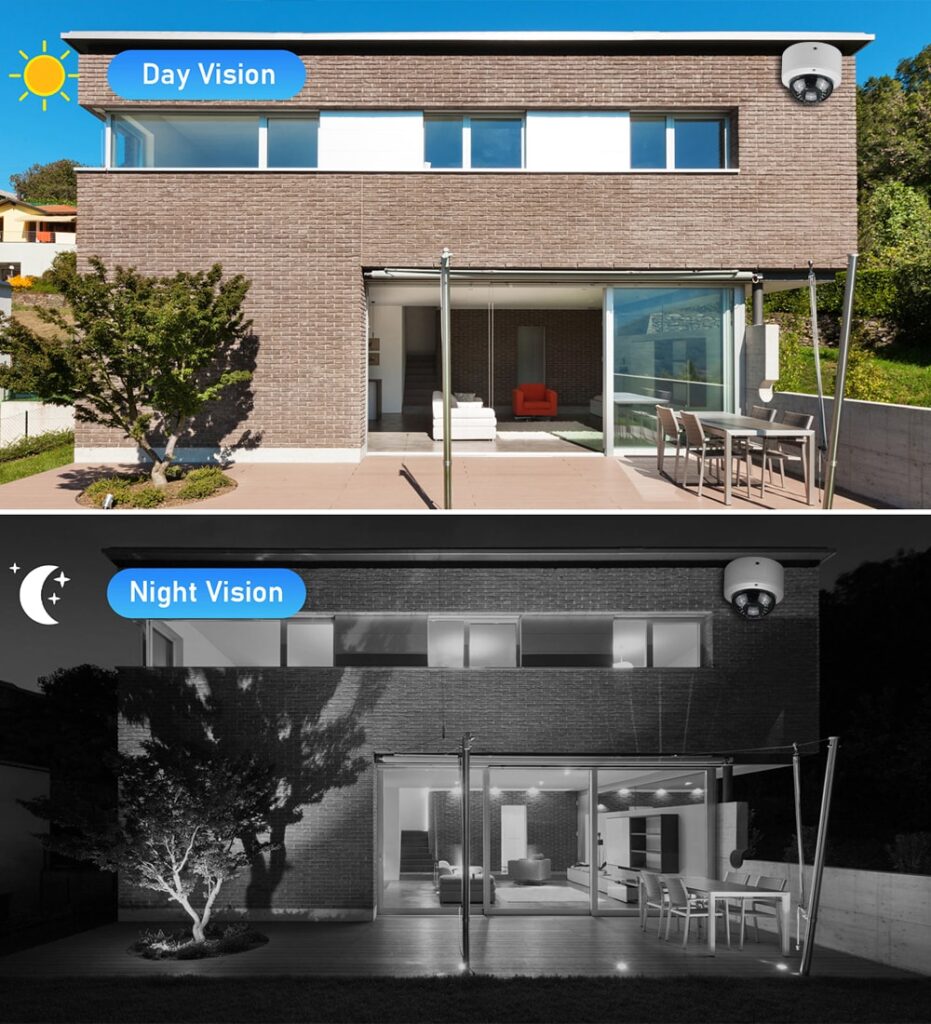

Pennsylvania’s weather presents a real challenge for exterior cameras. Hot, humid summers; snow and ice in winter; wind‑driven rain; and freeze‑thaw cycles can quickly destroy consumer‑grade devices. For yards, exterior dock walls, and perimeter fences, PA industrial surveillance cameras should have weatherproof housings (commonly IP66 or IP67 ratings) and robust operating temperature ranges that comfortably cover local extremes.

Ruggedness is about more than just waterproofing. Cameras placed near truck paths or areas prone to vandalism need impact‑resistant housings, secure mounts, and protected cable runs. For cameras mounted on poles in open yards, consider vibration‑resistant brackets and lightning/ surge protection to minimize downtime. In snowy climates within Pennsylvania, heaters and auto‑defog features can help keep domes and lenses clear, while sunshades reduce glare and overheating in direct summer sun.

You’ll also want to think carefully about how snow piles, parked trailers, and seasonal vegetation changes might block views. Before finalizing camera positions, walk the site in person, consider typical winter plowing patterns, and ask operators where they have seen past issues. The goal is to ensure that your investment in rugged PA industrial surveillance cameras delivers reliable coverage year‑round, not just in ideal conditions.

Costs, ROI and Insurance Benefits of PA Industrial CCTV Solutions

Budgeting for PA industrial surveillance cameras involves more than the list price of hardware. Typical cost components include cameras, lenses, NVRs or cloud subscriptions, storage drives, mounting hardware, cabling, network switches, installation labor, and configuration or training time. While line‑item pricing varies widely, many Pennsylvania warehouse operators phase projects, starting with the highest‑risk areas such as dock aprons, inbound and outbound staging, and yard gates.

The return on investment (ROI) often comes from a combination of reduced theft and shrink, fewer accidents and injury claims, and better utilization of labor and equipment. For example, clear video can help disprove fraudulent slip‑and‑fall claims, identify when damage occurred and who was responsible, or confirm that safety procedures were followed. Over time, these avoided costs can quickly exceed the initial investment in a robust CCTV system.

Another important angle is insurance. Many insurers view PA industrial surveillance cameras as risk‑reducing controls and may offer modest premium credits or be more willing to underwrite certain industrial operations if CCTV is in place. Even when premium reductions are small, video documentation can dramatically speed up claim handling, reduce disputes, and improve your loss history, which has long‑term financial benefits.

The table below illustrates how these factors can be considered at a high level:

| Consideration | Impact on PA industrial surveillance cameras project | Practical takeaway |

|---|---|---|

| Upfront equipment and install cost | Determines how much of the warehouse, yard and docks you can cover initially | Prioritize high‑risk zones; plan multi‑phase rollout. |

| Loss prevention and shrink reduction | Supports ROI through avoided cargo and asset theft | Track incident frequency before and after installation. |

| Safety and injury claim outcomes | Strong visual evidence can reduce or defend claims | Maintain clear camera views of docks and walkways. |

| Insurance perception and premiums | Demonstrates risk management to insurers | Share CCTV details with your broker or carrier. |

By quantifying even a portion of theft reduction, avoided downtime, or claim improvements, many Pennsylvania firms find that a well‑planned CCTV project pays for itself within a few years.

Installation Timeline and Downtime Planning for PA Warehouses

Installing PA industrial surveillance cameras in an active warehouse or yard requires careful planning to avoid disrupting operations. The timeline depends on project scope, cable routing complexity, and whether existing infrastructure (conduits, network, power) can be reused. A small dock‑focused project might take only a few days, while a full facility and yard rollout could span several weeks, often staged around operational windows.

A typical approach is to break the project into zones—such as inbound docks, outbound docks, yard gates, and interior aisles—and schedule work during lighter shifts, weekends, or planned maintenance periods. Coordination with warehouse supervisors ensures that lifts or scaffolding used for camera mounting do not block critical paths or emergency exits. Clear communication with carriers and drivers about any temporary lane closures near gates or docks is equally important.

To minimize downtime, many operators pre‑configure cameras and NVRs in a staging area, then perform quick swap‑outs or final mounting in the field. Testing is done zone by zone: verify each camera’s field of view, focus, motion detection or analytics, and recording. It’s also useful to conduct a “what‑if” drill after installation, replaying sample incidents to confirm you could see exactly what you’d need for an investigation.

If you’re looking for a partner that already understands how to work around active homes and businesses, S & Y Internet Technology’s installation and repair experience can be a strong fit. Their focus on efficient, on‑site services and clear communication helps keep disruption low while bringing new systems online quickly. You can explore their installation services in more detail and then request a site‑specific schedule and downtime plan that aligns with your Pennsylvania warehouse operations.

Pennsylvania Case Studies: Securing Warehouses, Yards and Docks

Every Pennsylvania facility is different, but some common patterns emerge when PA industrial surveillance cameras are deployed thoughtfully. A regional distributor might begin with a problem of missing pallets from an outbound staging area. After reviewing blind spots, they install new cameras that capture clear views of staging lanes, dock doors, and the exit gate. Within months, they identify and address process gaps and significantly reduce unexplained losses.

In another case, a manufacturing plant adds cameras to an employee parking lot and rear loading dock area where vandalism and unauthorized dumpster use have been issues. By pairing high‑resolution cameras with improved lighting and simple signage indicating video monitoring, incidents drop sharply. The plant also uses footage to optimize shift change traffic flow, reducing congestion and near‑misses at the lot entrance.

A third example might involve a 3PL operator managing multiple smaller warehouses across Pennsylvania. They deploy a standardized set of PA industrial surveillance cameras and recording equipment at each facility, all connected to a central monitoring platform. This lets a single security team oversee overnight operations statewide, respond to alerts from any site, and support clients with fast incident reviews. Over time, this centralized model can support new business wins by giving customers confidence in consistent security standards across all locations.

These scenarios illustrate that industrial CCTV is not just a “security expense” but a versatile tool for safety, process improvement, and customer trust across Pennsylvania’s warehouses, yards, and loading docks.

FAQ: Industrial CCTV Solutions for PA Warehouses and Loading Docks

What makes PA industrial surveillance cameras different from regular security cameras?

PA industrial surveillance cameras for warehouses, yards, and loading docks are chosen for ruggedness, higher resolution, better low‑light performance, and integration with industrial workflows. They are designed to handle harsh outdoor weather, dust, vibration, and the long coverage distances typical of industrial sites.

How many PA industrial surveillance cameras does a typical warehouse need?

The number of PA industrial surveillance cameras depends on facility size, risk areas, and required level of detail. Many Pennsylvania warehouses start by covering all dock doors, main interior aisles, yard gates, and any high‑value storage, then expand coverage to secondary areas as budget allows.

Can PA industrial surveillance cameras be viewed remotely on phones and laptops?

Yes. Most modern PA industrial surveillance cameras connect to NVRs or cloud platforms that allow secure remote viewing from mobile apps and desktop clients. With the right configuration, managers can monitor multiple PA sites from anywhere and quickly review recordings after an incident.

Do PA industrial surveillance cameras help with OSHA or safety compliance?

While cameras don’t replace required training or safety equipment, PA industrial surveillance cameras provide valuable documentation of real practices and near‑misses. Safety teams in Pennsylvania often use footage to coach behaviors, validate that dock procedures are followed, and improve signage or traffic patterns.

What about privacy concerns with PA industrial surveillance cameras in warehouses?

Employers must follow federal and state laws and communicate clearly with employees about the presence and purpose of PA industrial surveillance cameras. Cameras are typically focused on work areas, docks, entrances, and yards, not private spaces, and policies should cover how long footage is stored and who can access it.

Can existing lighting and network infrastructure support new PA industrial surveillance cameras?

In many Pennsylvania warehouses, existing lighting and network cabling can be partially reused, but a site survey is essential. Lighting may need to be upgraded in some dock or yard areas, and network switches or cabling might require upgrades to handle the bandwidth demands of modern PA industrial surveillance cameras.

Who should manage and maintain PA industrial surveillance cameras over time?

Some companies assign in‑house IT or facility teams to manage updates and basic troubleshooting, while others rely on service providers. Working with a provider like S & Y Internet Technology, which offers both installation and ongoing support for smart security devices, can simplify long‑term maintenance of PA industrial surveillance cameras across multiple sites. To discuss a service and maintenance plan that fits your Pennsylvania operations, consider reaching out to their team and sharing your facility list, current equipment, and support expectations.

Last updated: 2025-11-28

Changelog:

- Added detailed feature considerations for loading zone cameras.

- Expanded guidance on multi‑site remote monitoring and centralized control.

- Included additional examples of Pennsylvania‑style case scenarios.

- Clarified budgeting and ROI perspectives for PA industrial CCTV projects.

- Integrated spotlight on S & Y Internet Technology as a recommended provider.

Next review date & triggers

Review this guide in 6–12 months or sooner if your operations expand to new sites, insurance requirements change, or you plan a major security system upgrade that impacts PA industrial surveillance cameras.

About the Author: S & Y Internet Technology Inc.

S & Y Internet Technology Inc. is a professional installation and repair service provider based in Flushing, New York. Our expert team provides door-to-door installation and maintenance within a 100 km radius, ensuring quick response and high-quality results for every project — whether residential, commercial, or specialized.