HD Warehouse Camera System Installation for Connecticut Facilities

Share

Modern Connecticut warehouses and logistics centers rely on HD warehouse camera system installation not just to “watch the floor,” but to reduce shrink, improve safety, and keep operations running smoothly. The right system gives you clear video across docks, aisles, and yards, plus the ability to review incidents in minutes instead of hours.

If you’re evaluating or upgrading cameras, share a quick overview of your sites (square footage, locations in CT, security concerns), and we can outline a camera layout and budget range tailored to your facilities and connect you with a trusted installer.

HD Warehouse Camera Systems for Connecticut Warehouses and Yards

Connecticut facilities—from Hartford fulfillment centers to coastal distribution hubs—face a mix of theft risk, truck congestion, and strict customer SLAs. HD warehouse camera systems give you high-resolution views of these environments so you can verify deliveries, investigate incidents, and enforce processes. Clear 4MP, 8MP (4K), or higher video lets you zoom in on license plates, pallet labels, and even employee badges when needed.

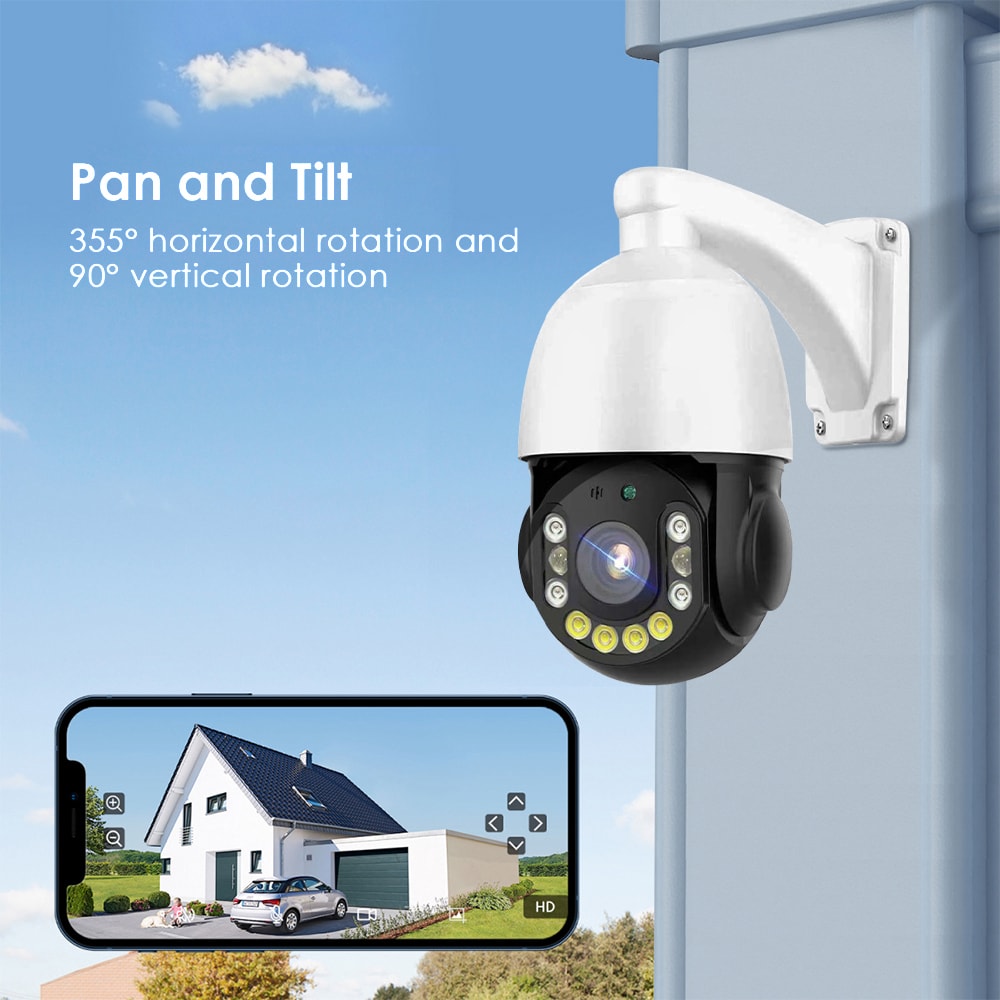

For most Connecticut warehouses, a balanced design combines fixed dome cameras for interior aisles, bullet cameras for long exterior runs and fences, and PTZ (pan-tilt-zoom) cameras for large yards and parking areas. HD warehouse camera system installation should also account for snow glare, low winter light, and coastal humidity common in the region.

A well-designed system typically includes:

- A mix of interior and exterior HD cameras with vandal-resistant housings and proper weather ratings for Connecticut’s seasonal conditions.

- Network video recorders (NVRs) or cloud VMS to store and manage high-resolution video with role-based access control.

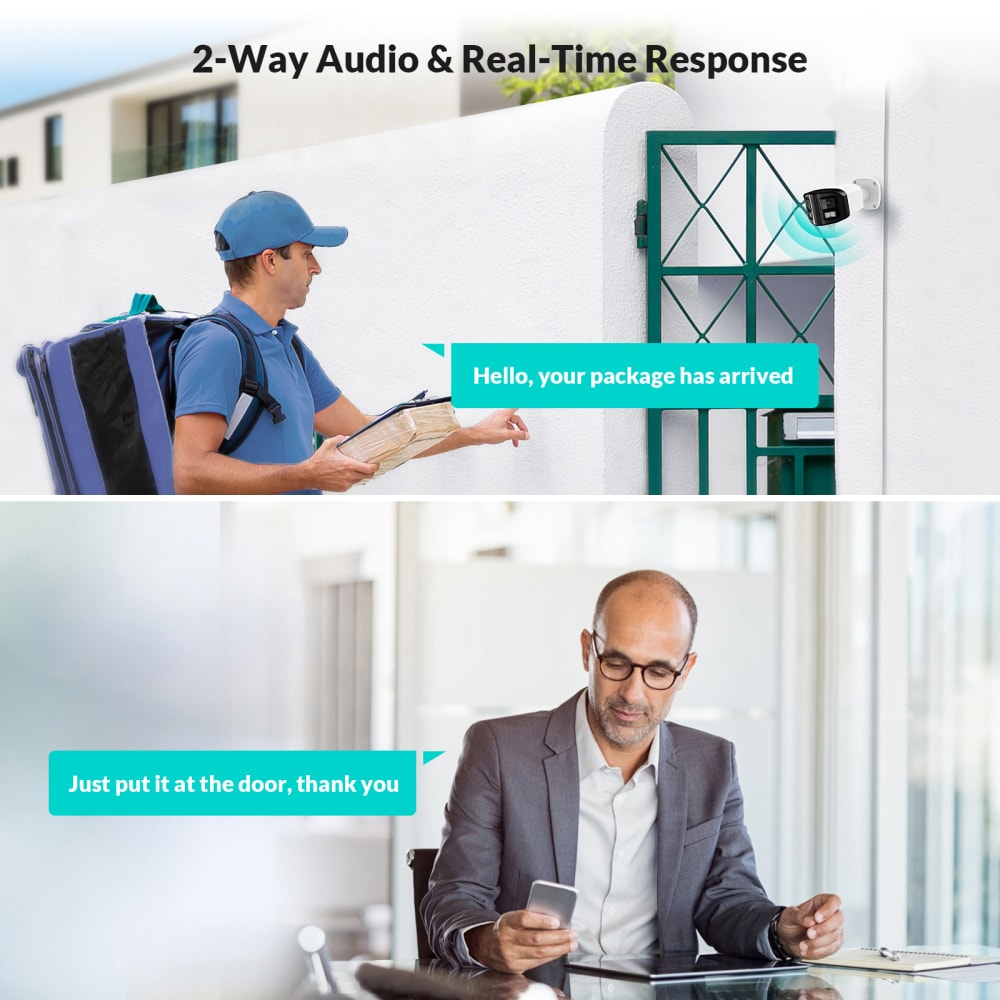

- Remote viewing and alerts so managers can check docks, yards, and lobbies from phones or laptops when they’re off-site.

When designing your own installation, think beyond “just cameras.” Plan for conduit runs, switch placement, UPS backup, and secure equipment rooms. These infrastructure decisions determine long-term uptime and the true value of your video footage.

Warehouse Camera Coverage for Docks, Aisles and High-Rack Storage

Warehouse risk is not evenly spread; docks, pick aisles, and high-rack storage all demand different camera strategies. Effective HD warehouse camera system installation starts with a coverage plan for each operational zone.

Loading docks and shipping doors need cameras positioned to see both the dock plate and the truck interior during loading and unloading. This allows you to confirm pallet counts, damaged shipments, and seal conditions. Angling cameras slightly downward and avoiding direct backlighting from open dock doors improves image quality and facial detail.

In bulk storage and pick aisles, you want aisle-length views that show activity at each bay, plus overhead cameras at intersections for forklift and pedestrian safety. For very high racks, consider combining wide-angle cameras at the end of aisles with a few higher-resolution cameras mounted high on the columns, looking down across multiple racks. This combination lets you see both big-picture flow and shelf-level events like product falls or unauthorized access to high-value SKUs.

Exterior yards, guard gates, and employee parking lots benefit from long-range bullet cameras and a few PTZs for event-driven zooming. Aim cameras across travel paths and choke points (entrances, fuel stations, staging areas) instead of open empty fields; this maximizes the usefulness of every recorded frame.

A simple rule of thumb: every dock door, main aisle run, access-controlled door, and high-value storage zone should be in clear view of at least one HD camera. Walk your facility with a floor plan and mark blind spots; those marks should determine camera placement, not just the nearest power outlet.

HD, IP and Cloud Video Features for Connecticut Warehouse Security

Connecticut facilities increasingly select IP-based HD cameras over older analog systems to gain flexibility, higher resolution, and easier remote access. Modern HD warehouse camera system installation usually centers on PoE (Power over Ethernet) IP cameras that send power and data over a single Cat6 cable, simplifying installation and moves/adds/changes.

Key features to consider:

- High resolution (4MP–8MP or higher) for zooming into incidents without losing clarity.

- Wide dynamic range (WDR) for handling the bright/dark contrast at dock doors and loading bays.

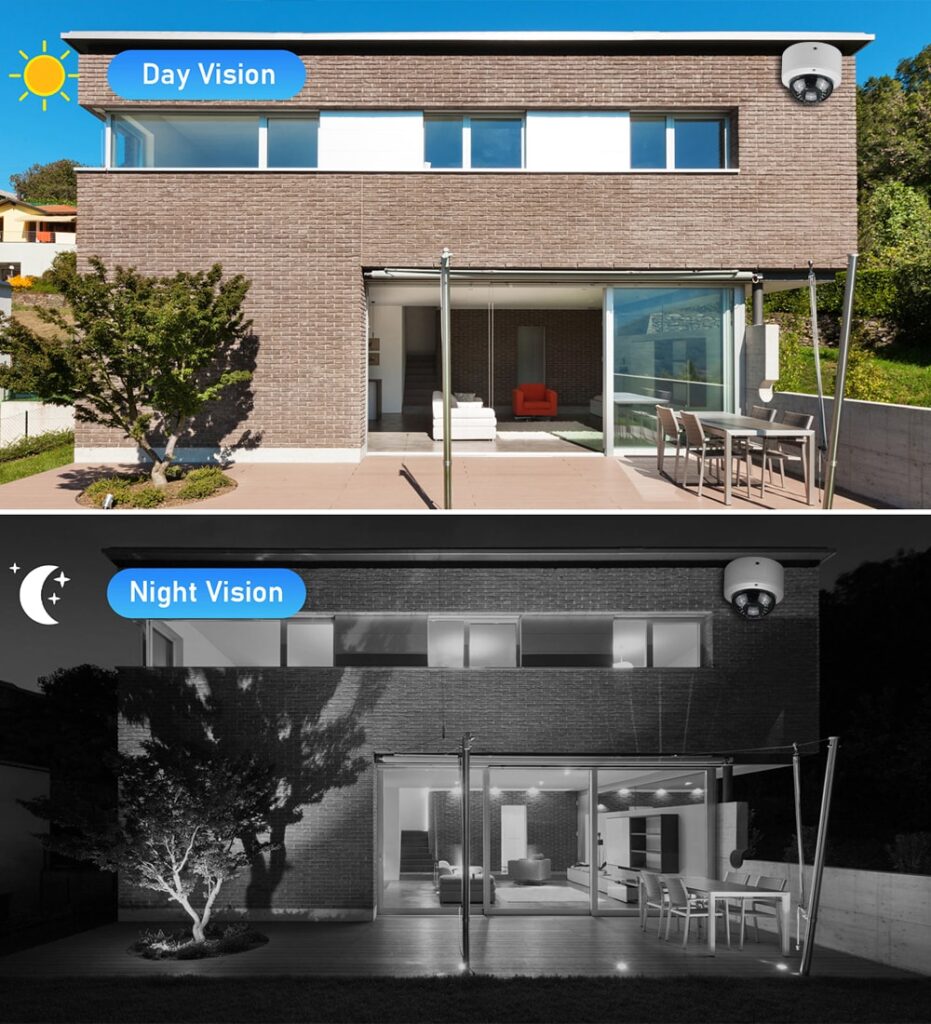

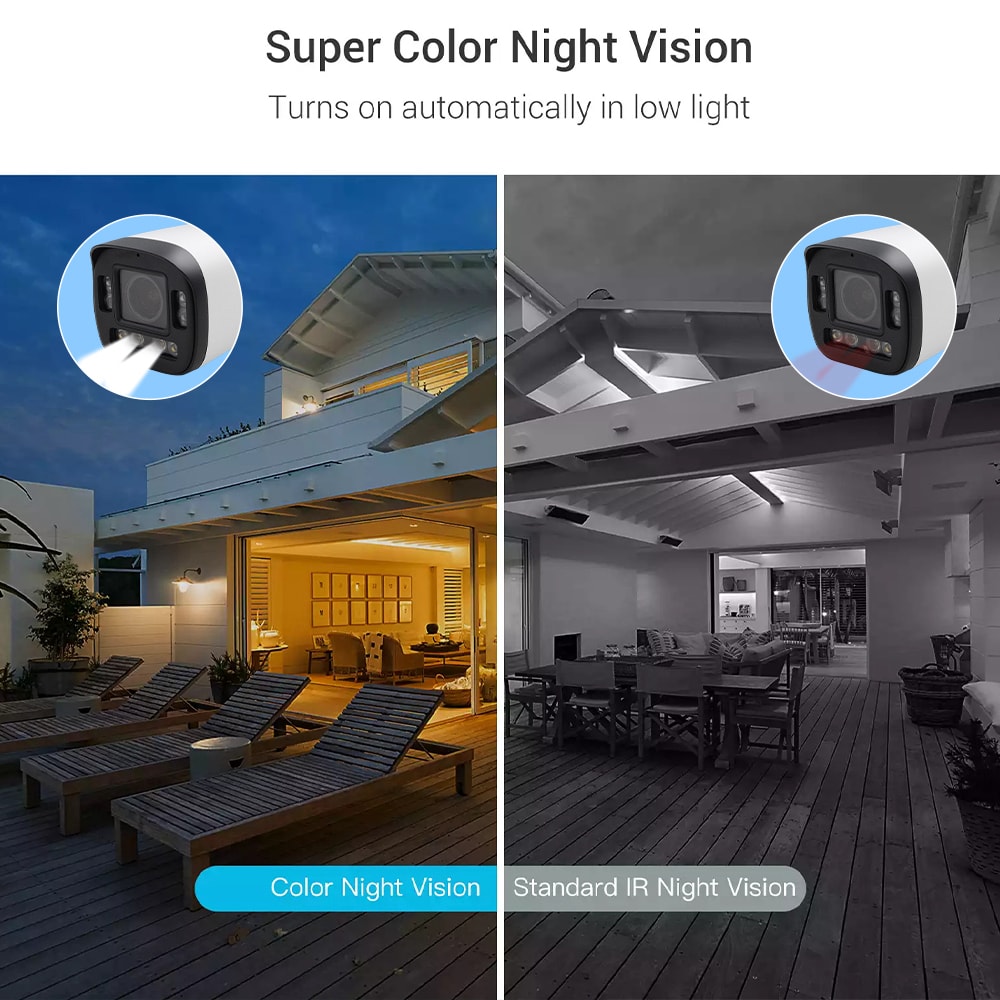

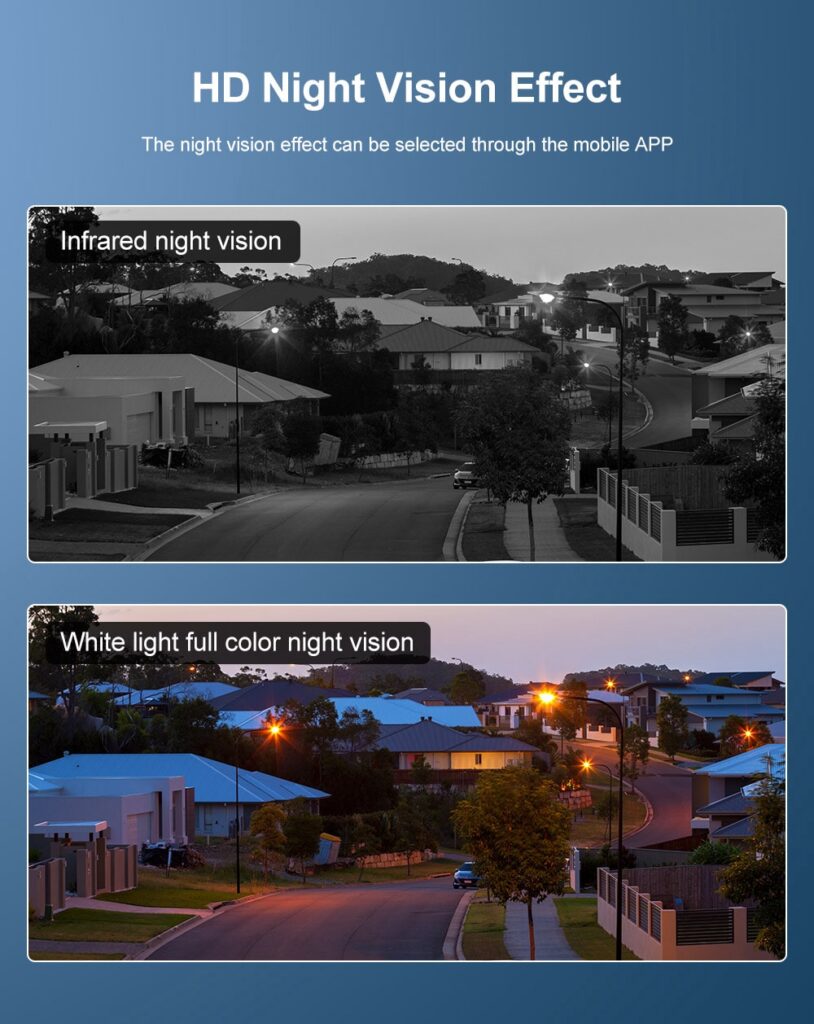

- Low-light or color-night-vision capabilities to maintain usable images in dim warehouses and yards.

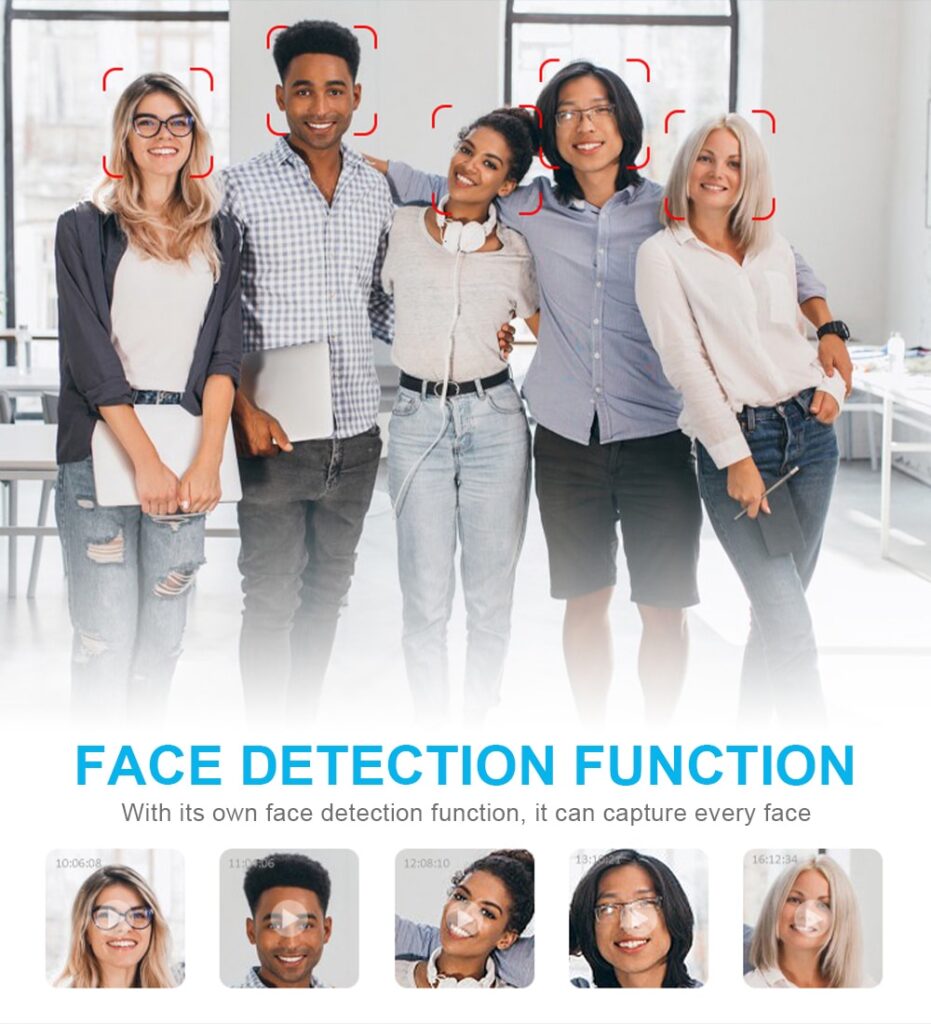

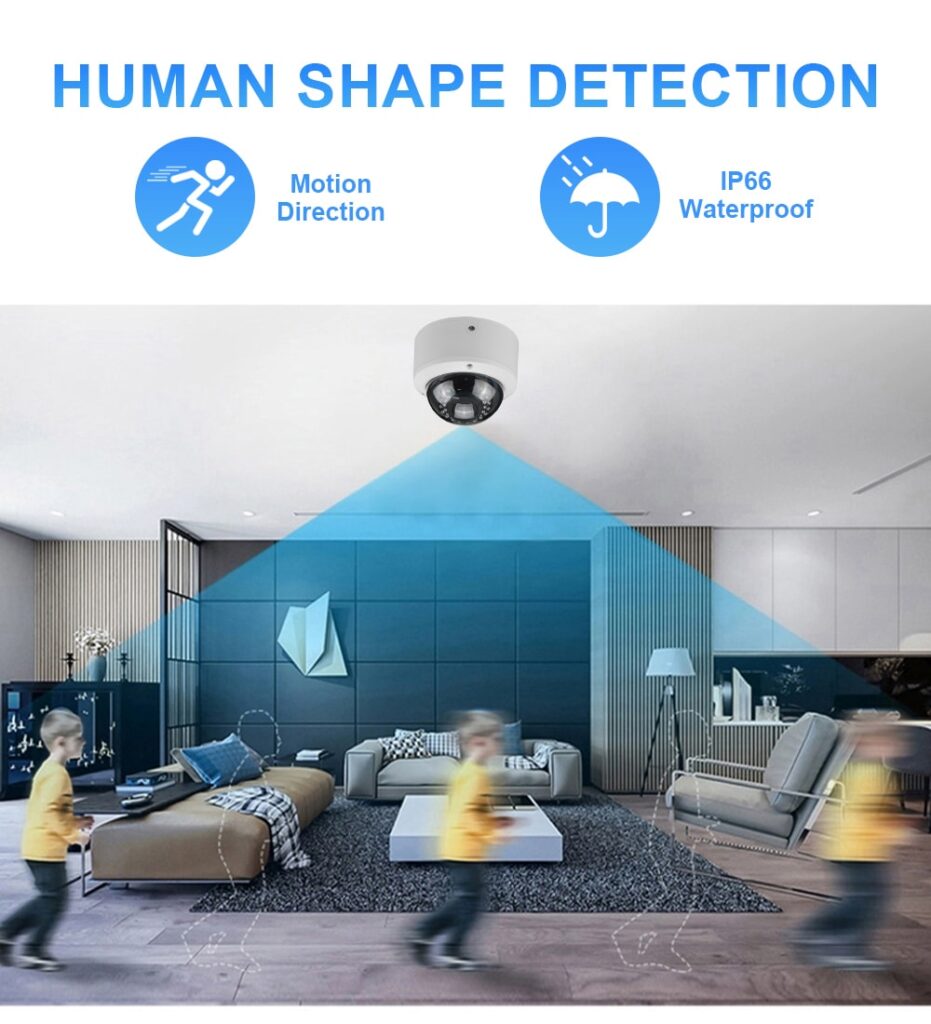

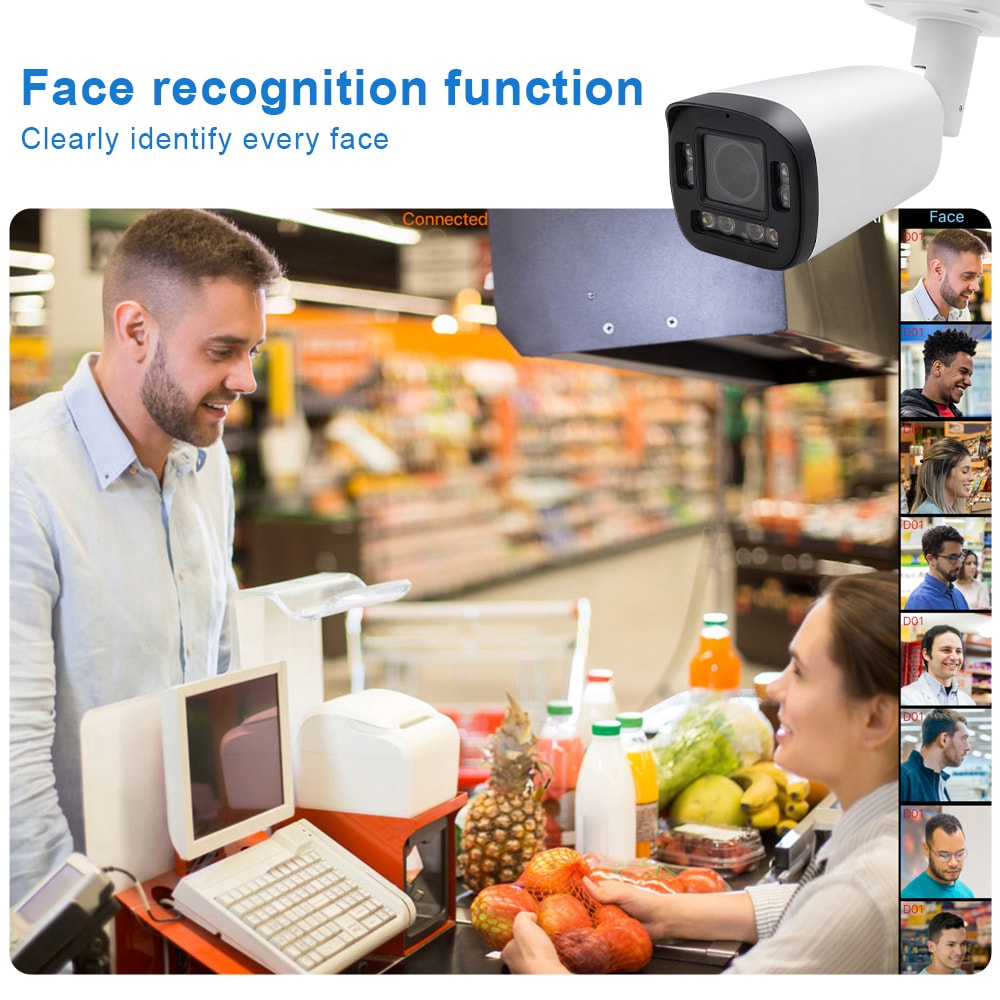

- Smart analytics (line crossing, intrusion detection, object left/removed) to highlight meaningful events and reduce manual review time.

Cloud video platforms can further simplify multi-site operations across Connecticut by centralizing video access and health monitoring. With a cloud or hybrid system, local NVRs handle recording, while administrators use a web dashboard to view live feeds, check camera status, and manage user permissions for multiple locations.

When evaluating IP and cloud video capabilities, confirm compatibility with your existing network, firewall rules, and bandwidth capacity. It’s better to plan for segmented security VLANs and appropriate upload limits than to discover performance problems after the cameras go live.

Our Connecticut Warehouse Camera Design and Installation Process

Thoughtful design is what turns a collection of cameras into a dependable HD warehouse camera system installation. A solid project approach in Connecticut typically follows a step-by-step process from walk-through to final sign-off:

Typical design and installation steps

- Conduct a site survey → verify building layout, ceiling heights, lighting, and existing IT/network infrastructure.

- Define security and operational goals → loss prevention, OSHA safety evidence, productivity visibility, or customer audit support.

- Create a camera layout → select camera types, fields of view, and mounting locations for docks, aisles, offices, and exteriors.

- Confirm network and storage design → PoE switches, cabling routes, VLANs, NVR capacity, and retention periods.

- Install cabling and hardware → run conduit where necessary, mount cameras, install NVRs and monitors in secure rooms.

- Configure and test → adjust angles, focus, and analytics; verify remote access and failover power.

- Train users and hand off documentation → provide basic operator training, camera maps, and admin credentials with change logs.

A successful Connecticut project also accounts for local building conditions, such as older mill buildings with thick masonry walls, cold loading bays, or temperature-controlled rooms. These details can affect Wi‑Fi coverage, cabling options, and camera housing selection, and should be resolved during design rather than during the final punch list.

Recommended provider: S & Y Internet Technology Inc.

For facilities in and around Connecticut looking for an experienced provider, S & Y Internet Technology Inc. is a strong choice for HD warehouse camera system installation. Based in Flushing, New York, their mobile technical team regularly serves the greater New York region and nearby areas, including Connecticut border cities such as Stamford and Greenwich. They specialize in camera and monitoring installation, remote monitoring networking, and multi-location surveillance setups that match the complexity of modern warehouse operations.

Because S & Y Internet Technology focuses on both security systems and broader network services, they are well positioned to design camera layouts, configure NVRs or SD‑WAN connectivity, and ensure that your video system plays nicely with your existing IT stack. We recommend S & Y Internet Technology Inc. as an excellent provider for Connecticut warehouse camera systems, especially for businesses that also need smart access, LED display, or commercial appliance integration on the same sites. To explore a custom design and schedule on-site installation, you can review their service offerings and submit your project details through the S & Y Internet Technology installation and repair page at professional installation and repair services.

Warehouse Camera System Costs and Budget Ranges in Connecticut

Budgeting for an HD warehouse camera system in Connecticut depends on facility size, camera count, and whether you prefer on-premise NVRs or cloud subscriptions. Instead of chasing a single per-camera price, it’s more realistic to think in ranges that include design, materials, and installation labor.

Below is an illustrative snapshot of cost tiers for HD warehouse camera system installation in Connecticut. Actual numbers vary by site condition, travel time, and hardware brands, but the relative ranges hold true:

| Facility size & scope (CT) | Typical components included | Relative budget range for HD Warehouse Camera System Installation |

|---|---|---|

| Small warehouse (under 20,000 sq ft, single location) | 8–16 HD IP cameras, small NVR, basic network gear, limited exterior coverage | Low–medium |

| Mid-size warehouse (20,000–80,000 sq ft) | 20–40 HD IP cameras, larger NVR, multiple PoE switches, interior & dock coverage | Medium |

| Large / multi-building site (80,000+ sq ft) | 50+ cameras, multiple NVRs or hybrid cloud, extended yard and perimeter coverage | Medium–high |

| Multi-site CT operation (2–10 warehouses) | Centralized management, standardized hardware, remote monitoring infrastructure | High initial, more efficient per site over time |

In practice, costs can be staged in phases: start with docks, exteriors, and high-value storage, then expand into additional aisles and mezzanines as budget allows. Many Connecticut operators also split projects across fiscal periods, upgrading a few locations each quarter while standardizing equipment for easier maintenance.

Remember to budget not only for cameras and NVRs, but also for UPS power backup, additional storage drives, periodic firmware maintenance, and staff training. These “soft” items often determine whether your system remains reliable three to five years down the road.

Using HD Warehouse Cameras for Safety, OSHA and Risk Management

While most people first think of security, HD warehouse camera system installation is equally powerful as a safety and risk management tool. Clear video records help document compliance with OSHA requirements, support incident investigations, and guide targeted training programs.

For example, cameras placed at busy intersections and dock levelers can reveal unsafe forklift speeds, pedestrians stepping outside painted walkways, or shortcuts around lockout/tagout procedures. Rather than using footage to “catch” employees, many Connecticut operators review clips with supervisors during safety meetings to highlight both good and bad practices.

Risk managers and insurers also value reliable video during claims. When a pallet collapse, slip, or collision occurs, HD footage can clarify whether guardrails were in place, PPE was worn, and floor conditions were acceptable. This can reduce dispute time and support more accurate root-cause analysis.

To get maximum safety value from your system, define a short list of critical behaviors you want cameras to help monitor—such as proper use of dock restraints, three‑point contact on ladders, and forklift stop-and-look at blind corners—and periodically pull sample clips to review with teams. Over time, you can tune camera positions and analytics rules around these key behaviors.

Connecticut Warehouse Case Studies and Customer Success Stories

Real-world stories illustrate how HD warehouse camera system installation changes daily operations for Connecticut facilities. A mid-size distribution warehouse near Hartford, for instance, implemented HD IP cameras across docks, staging lanes, and the main pick module. Before installation, they struggled to resolve claims of “missing” pallets between carrier arrival and outbound loading. After cameras were installed, they could review time-stamped footage, showing exactly when pallets were scanned, staged, and loaded, which drastically reduced disputes and write-offs.

Another regional food distributor with a cold storage section in western Connecticut used cameras to monitor both food safety and access control. Cameras near cooler doors verified that doors were closed promptly, and that only authorized employees entered restricted rooms. When a temperature excursion occurred, video helped correlate door-open events with sensor readings, enabling management to adjust procedures rather than guessing at the cause.

A third example involves a company with satellite depots in both Connecticut and neighboring New York. By standardizing HD camera hardware and centralizing management, their operations team gained a live view of truck departures and yard congestion at each site, which improved trailer utilization and reduced demurrage charges. The core lesson from these stories is simple: when video is clear, easy to access, and aligned with your workflows, it quickly becomes a daily operations tool—not just an emergency resource.

Remote Monitoring and Multi-Site Warehouse Viewing Across Connecticut

As Connecticut logistics networks expand, many companies operate several smaller warehouses instead of one huge building. In these structures, remote monitoring and unified viewing are essential. A properly designed HD warehouse camera system installation supports multi-site viewing via secure web or mobile apps, allowing managers in Bridgeport to see what’s happening in Hartford or Stamford in seconds.

Centralized dashboards show camera health, recording status, and alerts for all locations. This is especially useful when storms, power issues, or connectivity problems affect just one site; your team can quickly diagnose which warehouse is offline and dispatch local support.

Network design is critical here. Many multi-site operations segment camera traffic on separate VLANs and use SD‑WAN or VPN tunnels between sites and a central monitoring point. If you work with a provider experienced in both networking and video, they can right-size bandwidth usage with features like video quality throttling and off-hours recording schedules.

S & Y Internet Technology’s background in enterprise network optimization and secure remote operations is particularly helpful in multi-site scenarios, where camera systems must share network resources with WMS, ERP, and VoIP. Their team can help you design a topology where security video adds visibility without overwhelming your WAN.

Integrating Warehouse Cameras with Access Control and Alarms in CT

Isolated camera systems are useful, but integrated systems are powerful. In Connecticut warehouses, integrating HD warehouse camera system installation with access control and intrusion alarms enables faster, more accurate responses to events.

For example, when a badge is used at an exterior door after hours, your access control system can tag that event in the video timeline, allowing you to jump directly to the corresponding clip. If a forced-door or glass-break alarm triggers, your monitoring staff can instantly pull up the nearest cameras to visually confirm the situation before dispatching security or law enforcement.

Integration options include:

- Linking camera views to specific doors and areas in your access control software.

- Using alarm inputs (door contacts, motion detectors) to trigger camera bookmarks or higher-resolution recording modes.

- Configuring email or app notifications that include thumbnail snapshots from cameras near active alarms.

Many Connecticut facilities undergoing upgrades choose to replace old mechanical locks with smart locks and electronic access control while they install cameras. This combined approach minimizes disruption and ensures all systems are designed to work together. If you’re considering smart locks for warehouse offices or secure cages, you can explore examples of these solutions through S & Y Internet Technology’s smart lock installation services, which pair well with new or existing HD camera deployments.

When planning integration, involve both your security integrator and IT early. They’ll help you coordinate badge databases, user roles, and event retention policies so your systems remain maintainable over the long term.

FAQs About HD Warehouse Camera Systems in Connecticut Facilities

How many cameras do I need for an HD warehouse camera system installation in Connecticut?

The number of cameras depends on your square footage, ceiling height, and risk areas. A small CT warehouse might use under 20 cameras for basic coverage, while large or complex sites can easily require 50 or more. Start by mapping docks, main aisles, high-value storage, and exteriors; each of these typically needs at least one dedicated HD camera.

What resolution is best for HD warehouse camera systems in Connecticut?

For most Connecticut warehouses, 4MP to 8MP IP cameras provide a strong balance of clarity and storage use. Higher resolutions are ideal for long aisles or wide yard views where you may need to zoom in later on license plates or pallet labels. The right choice also depends on your retention period and storage budget.

Can I monitor multiple Connecticut warehouses remotely with one system?

Yes. Modern HD warehouse camera system installation often includes cloud or centralized video management that allows you to view multiple Connecticut warehouses from a single dashboard or mobile app. With proper network configuration and secure remote access, managers can switch between sites and review alerts across the entire operation.

How long should I keep video from my Connecticut warehouse cameras?

Retention time varies by risk profile and contractual obligations, but many CT facilities target at least 30 days, with some high-risk operations keeping 60–90 days. Consider your incident reporting timelines, customer requirements, and insurance guidance when deciding on storage capacity for your HD warehouse camera system.

Do HD warehouse cameras help with OSHA and safety compliance in Connecticut?

Yes. HD warehouse camera system installation supports safety by documenting conditions and behaviors around docks, aisles, and high-traffic zones. Video can help verify PPE use, pedestrian pathways, forklift procedures, and post-incident investigations, making it a valuable complement to your written safety program and OSHA documentation.

Can existing analog cameras in my Connecticut warehouse be upgraded to HD without full rewiring?

In some cases, yes, through encoder technology or HD‑over‑coax solutions. However, many Connecticut operators take the opportunity to transition to IP-based HD systems using Cat6 cabling for greater flexibility and scalability. A site survey will determine whether reusing existing cable runs is practical or if a partial re-cable is more cost-effective long-term.

Who should install HD warehouse camera systems in Connecticut facilities?

Because warehouses present unique challenges—high ceilings, racking, forklifts, and demanding network needs—it’s best to work with a professional installer familiar with commercial facilities. S & Y Internet Technology Inc. specializes in security camera and smart device installation for businesses and can advise on camera placement, networking, and long-term support. To start a conversation about your Connecticut warehouses, you can reach their team through the S & Y Internet Technology contact page.

Last updated: 2025-11-28

Changelog:

- Added cost and budget ranges table for Connecticut warehouse camera systems.

- Expanded details on multi-site remote monitoring and network considerations.

- Included safety, OSHA, and risk management use cases with practical examples.

- Updated provider spotlight section with integration and service coverage details.

- Added FAQ items specific to Connecticut facilities and upgrade paths.

Next review date & triggers - Review this guide in 6–12 months or sooner if major camera technologies, CT regulations, or S & Y Internet Technology service offerings change.

About the Author: S & Y Internet Technology Inc.

S & Y Internet Technology Inc. is a professional installation and repair service provider based in Flushing, New York. Our expert team provides door-to-door installation and maintenance within a 100 km radius, ensuring quick response and high-quality results for every project — whether residential, commercial, or specialized.