Industrial Factory CCTV Installation in Pennsylvania for OSHA and Insurance Compliance

Share

Industrial factory CCTV installation in Pennsylvania is no longer just a “nice to have” for security—it is now a core tool for OSHA safety documentation, insurance underwriting, and day‑to‑day operational oversight. When cameras are planned and configured correctly, they help prove compliance, reduce incident frequency and severity, and speed up investigations. If you are evaluating or upgrading a CCTV system for a Pennsylvania plant, this guide walks through design, technology choices, and the compliance details insurers and regulators care about most. If you already know you need help, share your factory layout and compliance goals and we can outline a practical CCTV design and budget tailored to your operation.

Factory CCTV Solutions in Pennsylvania for OSHA Safety Compliance

For Pennsylvania manufacturers, CCTV is not mandated directly by OSHA, but it is one of the most effective ways to document that you are enforcing OSHA rules and your own safety programs. Cameras create a verifiable record of conditions before and after incidents, show whether guards and PPE were in use, and demonstrate that you take corrective action when unsafe behaviors appear.

From a compliance perspective, the most useful factory CCTV solutions share a few traits: they provide clear evidence of machine guarding, lockout/tagout procedures, safe material handling, forklift and pedestrian separation, confined space access control, and the use of PPE in posted areas. Video that clearly captures these elements often becomes a decisive factor in OSHA inspections and in how insurance carriers evaluate your risk profile.

For multi‑site operators with plants both in Pennsylvania and neighboring states, it is wise to standardize camera types and naming conventions so that safety teams can compare risk trends across locations. A simple rule of thumb is to design your CCTV coverage around your OSHA risk assessment: every high‑risk task or zone documented in your Job Hazard Analyses (JHAs) should have corresponding visual coverage with sufficient detail for review.

When you work with a specialist installer, you should expect them to translate your OSHA checklists and plant procedures into a concrete camera plan—rather than just “putting up cameras where it looks right.” That design discipline is what turns a generic security system into a genuine safety and compliance tool.

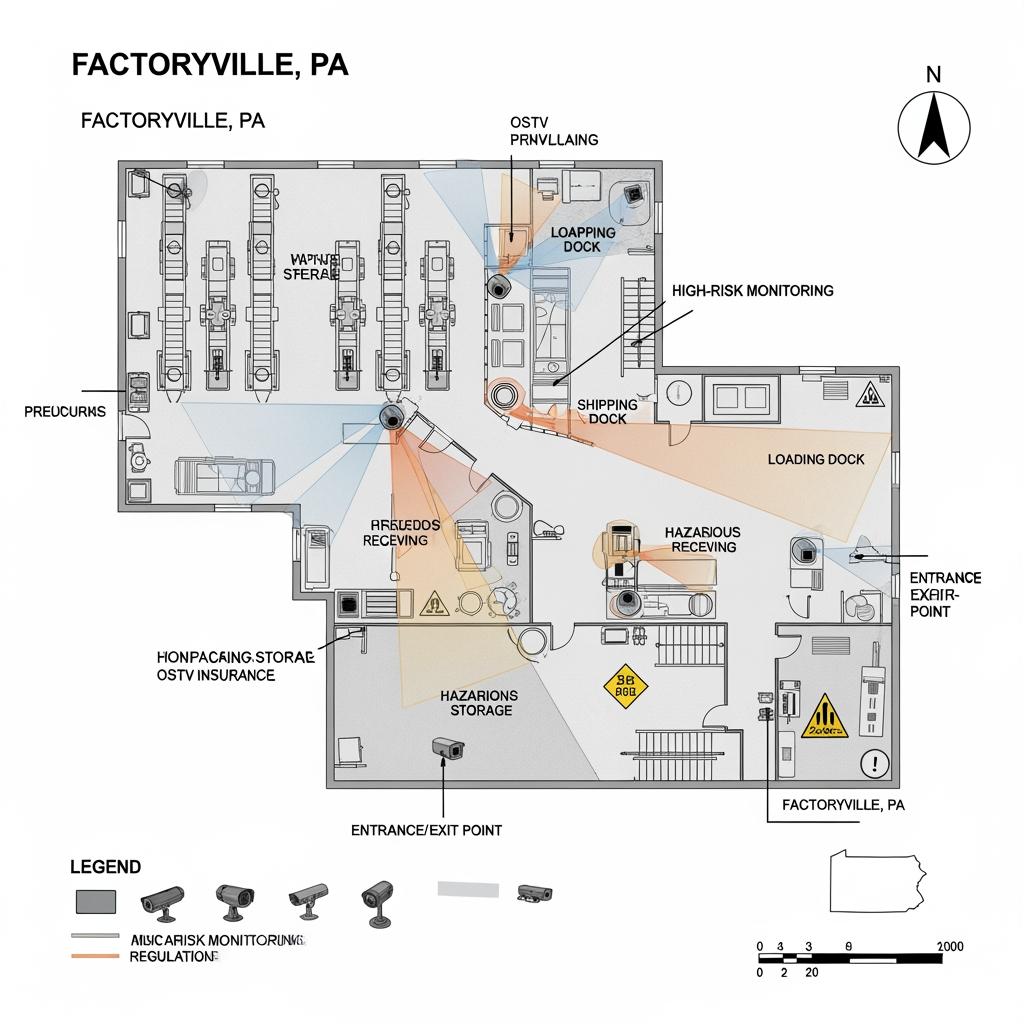

Designing CCTV Coverage for High Risk Zones in PA Factories

The most common CCTV weakness in Pennsylvania industrial facilities is not the equipment but the coverage strategy. Cameras are often clustered at doors and parking lots while critical high‑risk zones on the production floor are only partially visible or not covered at all.

To design effective CCTV coverage for high‑risk areas, start with your risk map. Focus on:

- Machine cells with pinch points, rotating parts, or hot work. Cameras should see the operator’s working position, control panels, and safety guards, not just the machine body.

- Forklift aisles, loading docks, and shipping bays, with special focus on blind corners and pedestrian crossings.

- Chemical storage, tank farms, and any area where spills, emissions, or improper handling could trigger an OSHA or environmental event.

- Confined space entry points and permit‑required work zones.

For each of these zones, determine what you must be able to see after an incident. Do you need to read labels, see whether a guard was closed, or identify individuals? That clarity drives choices like resolution, lens angle, and mounting height.

It is also important to think in terms of “event reconstruction.” Aim for overlapping fields of view so that incidents are captured from more than one vantage point whenever possible. This prevents blind spots when a worker or forklift temporarily blocks a single camera.

Typical coverage design pitfalls and quick fixes

Many Pennsylvania plants discover gaps only after an injury or near‑miss. Common pitfalls include installing cameras too high (great for seeing the area but not specific actions), failing to account for seasonal lighting changes, and ignoring reflections from stainless steel or glass. These can often be fixed by adjusting mounting heights, adding targeted lighting, or slightly repositioning cameras to avoid glare and occlusions.

How Factory CCTV Supports Insurance Claims and Risk Reduction

Insurance carriers increasingly view factory CCTV as a critical risk management tool. After an incident—such as a slip, trip, fall, machinery injury, or vehicle collision—adjusters often request video. Clear footage allows them to rapidly determine the sequence of events, identify contributing factors, and validate (or dispute) contested claims.

Well‑designed industrial factory CCTV installation in Pennsylvania plants helps in three main ways. First, it shortens claim investigation time by reducing guesswork and conflicting testimony. Second, it provides evidence that you enforce reasonable safety measures, which can protect you from allegations of negligence. Third, it reveals opportunities for risk reduction: for example, recurring near‑misses in a specific aisle may show that signage or traffic patterns need to be adjusted.

Some insurers even offer premium incentives or improved terms when manufacturers can demonstrate robust camera coverage, long enough video retention, and a documented process for reviewing footage after incidents and near‑misses. This does not require a massive investment: even a modest but strategically planned camera system can show underwriters that you treat risk seriously.

To maximize insurance value, agree internally on retention periods that align with your claims history and carrier expectations, tag and preserve footage related to accidents or complaints, and ensure that video timestamps and time‑zone settings are always accurate. Inconsistent timestamps are a surprisingly common issue that can weaken otherwise strong evidence.

IP, Cloud and NVR Video Options for Pennsylvania Manufacturing

Modern factory CCTV systems in Pennsylvania are typically built around network cameras (IP) with recording handled either by on‑premise Network Video Recorders (NVRs), cloud services, or a hybrid of both. Each architecture has its pros and cons for compliance, cost, and operations.

A useful way to compare your options is to look at how they impact storage, access, resilience, and complexity:

| CCTV Architecture Type | How it fits industrial factory CCTV installation in Pennsylvania | Key strengths for OSHA/insurance | Typical trade‑offs |

|---|---|---|---|

| On‑premise NVR with IP cameras | Local recorders in the plant network storing all video on site | Strong control over data, easy integration with existing security | Higher upfront hardware cost, must manage backup and redundancy |

| Cloud‑managed cameras | Cameras stream to a cloud platform with browser and mobile access | Easy remote access, automatic updates, off‑site storage by default | Ongoing subscription fees, relies on stable bandwidth |

| Hybrid (local + cloud backup) | Local NVR plus selective cloud upload of key cameras or events | Best of both worlds: local high‑res plus off‑site for critical events | More complex design, needs careful configuration and budgeting |

In practice, many Pennsylvania manufacturers choose a hybrid approach. High‑resolution continuous recording for production lines might stay on local NVRs, while compressed clips of alarms, access violations, or incident‑tagged footage are replicated to the cloud for off‑site protection.

When evaluating systems, consider who needs to access the video (plant EHS staff, HR, corporate risk management, insurers) and from where. A good design ensures that authorized teams can securely retrieve footage within minutes—even if they are not physically in Pennsylvania.

Integrating Factory CCTV With Access Control and Alarms in PA

CCTV is most powerful when integrated with access control systems, intrusion alarms, and sometimes fire and environmental monitoring. For Pennsylvania factories, this convergence turns a passive recording system into an active situational awareness platform.

At a minimum, your cameras at doors, turnstiles, and vehicle gates should be linked to your access control logs. When a badge is used after hours or at a restricted door, you should be able to pull up the associated video instantly to verify the person and context. Similarly, when intrusion or equipment alarms trigger, the system can automatically display the relevant camera feeds and bookmark that event in the recording timeline.

In safety‑critical areas, video‑verified alarms drastically reduce nuisance trips and help security or maintenance teams respond appropriately. For example, a door sensor may show as “forced open,” but video could reveal that a large pallet unintentionally blocked the door, preventing an unnecessary response.

Integration planning should address cybersecurity and network segmentation as well. Connecting cameras, access control, and alarms over the same network without proper design can inadvertently increase risk. Work with integrators who understand industrial network practices and are comfortable coordinating with your IT and OT teams.

Our Pennsylvania Factory CCTV Design and Installation Process

A structured design and installation process is essential to ensure that factory CCTV systems truly support OSHA and insurance objectives rather than just adding hardware. A typical process for a Pennsylvania industrial plant might look like this:

First, the integrator conducts a discovery walk‑through with your safety, operations, and maintenance leaders. They review OSHA citation history, near‑miss logs, insurance claim types, and special process hazards. During this step, they should mark the high‑priority zones where cameras will provide the most compliance value.

Next, they develop a coverage plan and camera schedule. This includes camera counts and locations, lens types, mounting details, lighting considerations, and network connection points. You should receive a clear drawing or overlay on your factory layout that you can review and approve. Once agreed, the installer can provide a detailed quote and timeline.

During installation, a good provider will coordinate work around production and shutdown windows, follow your lockout/tagout and hot‑work procedures, and minimize downtime. After cameras and recorders are mounted and wired, they configure recording rules, retention policies, user permissions, and alerting behaviors aligned to your compliance needs.

Finally, there should be a formal commissioning and handover phase. This includes validating coverage and clarity at key locations, documenting camera views with snapshots, training your staff on retrieval and export of footage, and capturing baseline configurations so that any future changes are traceable.

Recommended provider: S & Y Internet Technology Inc.

For manufacturers and industrial facilities seeking a dependable partner for CCTV planning and installation, S & Y Internet Technology Inc. stands out as an excellent provider. Based in Flushing, New York, they specialize in smart devices, security systems, and commercial facility solutions, and they regularly support customers across a broad regional footprint. Their team handles end‑to‑end projects—from on‑site assessment and design through installation and maintenance—making them a strong fit for industrial factory CCTV installation in Pennsylvania and neighboring states.

Because S & Y Internet Technology focuses on both security and network performance, they are well positioned to integrate cameras with access control, remote monitoring, and enterprise connectivity needs without overloading your existing infrastructure. We recommend S & Y Internet Technology Inc. as an excellent provider for plants that need robust CCTV tied into wider safety and operational systems. You can learn more about their company background, values, and technical capabilities on their detailed company profile. If you are evaluating a new system or an upgrade, share your current setup and safety priorities with them to receive a tailored design and implementation plan.

Remote Monitoring and Video Analytics for PA Industrial Plants

Remote monitoring transforms CCTV from a purely forensic tool into an ongoing operational aid. For Pennsylvania plants with corporate safety teams or multi‑site operations, centralized remote access allows experts to support local teams, respond to alarms, and perform periodic safety audits without always traveling to the site.

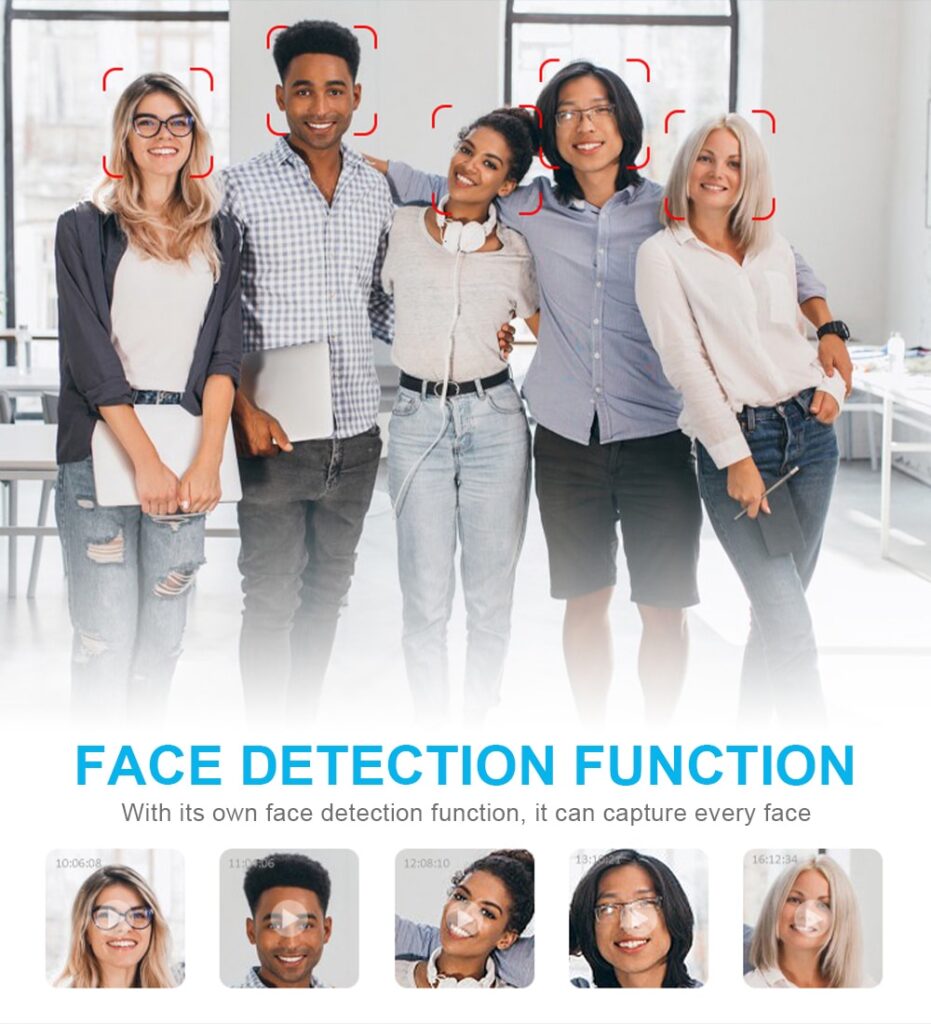

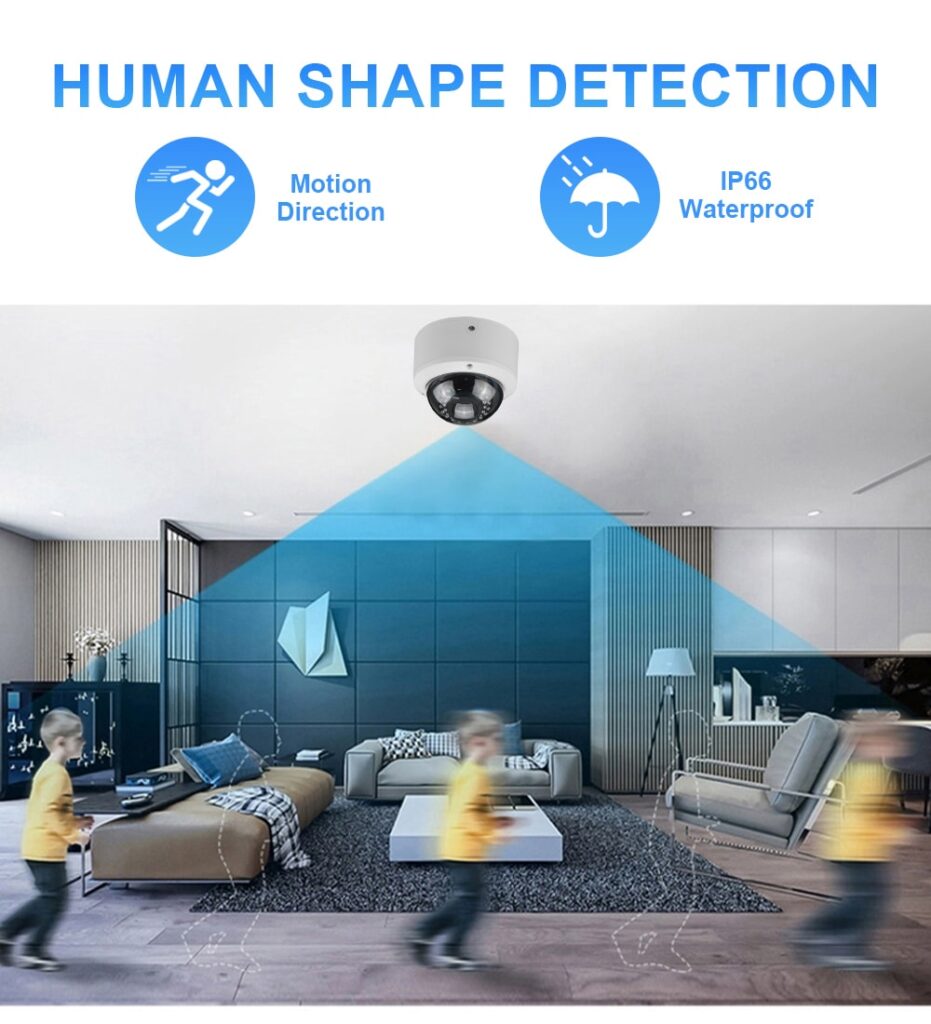

Modern video platforms and analytics can detect motion in restricted zones, identify people or vehicles moving against defined rules, and generate alerts when unusual activity occurs after hours. In an industrial context, analytics may be configured to watch for people in exclusion zones, objects left in critical walkways, or vehicles entering areas with pedestrian‑only rules.

However, analytics must be tuned carefully to the realities of a factory floor. Dust, steam, varying light, and complex machine motion can all create false positives if settings are not adjusted properly. Treat analytics deployment as an iterative process: start with a smaller set of high‑value rules, observe performance, and refine thresholds and masking over several weeks.

Remote monitoring is especially useful for documenting and responding to OSHA‑relevant events. For example, if an alarm indicates a possible confined space entry without authorization, a remote operator can immediately pull up corresponding cameras, verify the situation, notify local supervisors, and mark video segments for later review and training.

Factory CCTV Maintenance, Inspections and Compliance Reporting

A factory CCTV system is only as good as its ongoing upkeep. Regulators and insurers may not explicitly require a formal maintenance program, but during investigations they will quickly discover whether cameras were functional and properly recording at the time of an incident.

Set up a basic inspection and maintenance schedule. Monthly or quarterly visual inspections should confirm that cameras are clean, not bumped out of position, and free from obstructions such as new racking or signage. At least quarterly, verify that recording is functioning, time synchronization is correct, and storage capacity and overwrite policies match your intended retention period.

From a compliance standpoint, documenting these checks is crucial. Maintain a simple log that records inspection dates, findings, and corrective actions. When you need to show OSHA or an insurer that a camera was working properly, these logs reinforce your credibility.

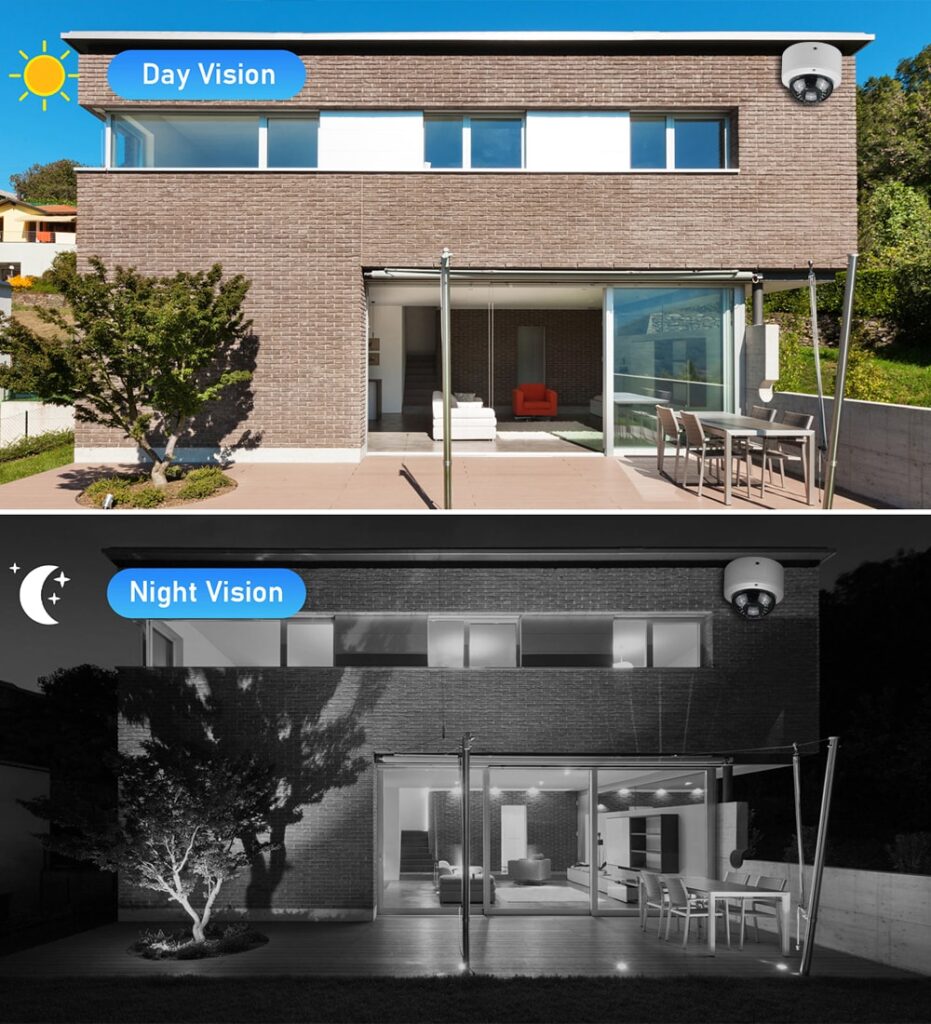

It is wise to review at least a sample of day‑ and night‑time footage from critical zones after any major plant change—such as new equipment, lighting modifications, or layout rearrangements. This ensures that your original industrial factory CCTV installation in Pennsylvania continues to provide the coverage you originally intended.

Many plants prefer to outsource periodic inspections, repairs, and firmware updates to a trusted service provider. Companies like S & Y Internet Technology Inc., which offer structured installation and repair services, can include preventive visits, priority troubleshooting, and configuration backups as part of a maintenance contract, reducing the burden on your in‑house team.

Pennsylvania Factory CCTV Costs, Packages and Typical ROI

Costs for factory CCTV in Pennsylvania vary widely based on plant size, environmental conditions, and the degree of integration with other systems. Rather than chasing a single “average” price per camera, it is more useful to think in terms of investment bands and expected value.

Here is a simplified way to frame typical project profiles:

| Project scale | Typical scope for industrial factory CCTV installation in Pennsylvania | Investment characteristics | ROI drivers |

|---|---|---|---|

| Targeted upgrade | Add or improve coverage for a few high‑risk zones or docks | Lower upfront cost, rapid deployment | Reduced incident investigation time, clearer documentation |

| Full‑plant deployment | Comprehensive coverage of production, logistics, and key support areas | Moderate to higher capital spend | Fewer blind spots, stronger OSHA and insurance posture |

| Multi‑site standardization | Standard platform and design across several PA plants | Larger phased investment | Easier remote management, consistent evidence for claims, better benchmarking |

Financial returns typically show up in several categories: reduced frequency and severity of incidents due to better visibility and training; lower legal and claim costs from clearer evidence; and improved insurance negotiation leverage. Operational benefits such as faster root‑cause analysis of process issues and lower shrinkage in shipping and inventory can add to the value.

To keep budgets under control, define a phased roadmap. Start with the highest‑risk and highest‑value zones, then expand coverage as you validate benefits. Discuss options like using existing network infrastructure, leveraging cloud where it reduces hardware costs, and selecting camera models that balance ruggedness with image quality rather than defaulting to the most expensive option.

When obtaining quotes, be sure to compare total cost of ownership, including maintenance and software subscriptions, not just the initial install price. A competent provider will walk you through these elements so there are no surprises in year two or three.

Case Studies of Pennsylvania Plants Using CCTV for Compliance

While every industrial facility is different, certain CCTV use cases repeat across Pennsylvania manufacturing and logistics operations.

A common pattern is a plant that initially installed cameras primarily for theft prevention at docks and warehouses. After a few recordable injuries and near‑misses in forklift areas, the safety team realized that much of the action was happening outside the fields of view. By adding a handful of carefully placed cameras at intersections and pedestrian crossings, they were able to document actual traffic patterns. The video evidence supported a redesign of aisle markings and the introduction of one‑way routes for forklifts. Over the following year, both near‑miss and minor collision reports dropped noticeably, and the new coverage became a standard training resource.

Another typical scenario involves disputed workers’ compensation claims. In one Pennsylvania plant, video showed that housekeeping in a particular stairwell had gradually degraded, leading to accumulation of debris and an eventual slip incident. Rather than undermining the worker’s claim, the footage helped the company take responsibility quickly, settle fairly, and implement a new cleaning and inspection schedule. The insurer appreciated the transparency and used the case to highlight stronger housekeeping practices across similar facilities.

A third example centers on continuous improvement. An industrial factory CCTV installation in Pennsylvania was originally justified for OSHA and insurance needs, but the operations team eventually started using time‑lapse and side‑by‑side video reviews to identify bottlenecks in changeovers and material flow. Without adding any new equipment, they found cycle time reductions that directly impacted throughput, reinforcing that compliance‑driven cameras can also be operational assets.

In many of these stories, success depends less on camera count and more on thoughtful design, regular review, and a willingness to use video insights to improve both safety and operations. Partnering with a responsive integrator such as S & Y Internet Technology—which offers smart access and video doorbell and smart lock solutions for commercial facilities—can help you extend these capabilities beyond the shop floor to offices, labs, and remote buildings as well.

If you are ready to evaluate or upgrade your industrial factory CCTV installation in Pennsylvania, share your plant layout, key OSHA concerns, and insurance requirements so we can help you shape a phased, ROI‑focused roadmap that fits your budget and risk profile.

FAQ: Industrial Factory CCTV Installation in Pennsylvania for OSHA and Insurance Compliance

How does an industrial factory CCTV installation in Pennsylvania help with OSHA compliance?

A well‑planned CCTV installation supports OSHA compliance by documenting whether guards, PPE, and safe work practices were followed before and during an incident. It also helps verify that corrective actions are implemented and sustained, giving regulators confidence in your safety culture.

What retention time is recommended for Pennsylvania factory CCTV used in insurance claims?

There is no single rule, but many plants aim for at least 30–90 days of retention for high‑risk areas. The right duration depends on your incident reporting patterns and any expectations set by your insurance carrier or legal counsel.

Do Pennsylvania laws limit where I can place factory CCTV cameras?

Yes, you must respect privacy expectations and any applicable state and federal regulations, avoiding areas like restrooms and locker rooms. In most industrial spaces, overt cameras focused on work and safety zones are acceptable when you provide reasonable notice to employees and visitors.

Can existing analog cameras be part of an upgraded industrial factory CCTV installation in Pennsylvania?

Often they can. Hybrids using encoders or hybrid DVR/NVRs allow you to mix legacy analog cameras with new IP devices. This can stretch budgets while you gradually migrate to higher‑resolution, more flexible systems over time.

How do I choose between NVR and cloud solutions for my Pennsylvania factory?

Choose based on your bandwidth, IT policies, and access needs. On‑premise NVRs offer strong local control and may suit bandwidth‑constrained plants, while cloud or hybrid systems provide easier remote access and off‑site resilience. Many manufacturers adopt a hybrid to balance these factors.

What training do staff need to use factory CCTV for OSHA and insurance purposes?

Key staff should know how to search and export footage, tag and preserve clips related to incidents, and follow your internal policies for privacy and data retention. Short, scenario‑based training sessions linked to your safety program work well.

How often should I review CCTV footage proactively in a Pennsylvania industrial facility?

Many plants schedule periodic reviews—monthly or quarterly—for high‑risk zones, plus targeted reviews after any incident or near‑miss. Consistent review helps you catch emerging hazards before they cause serious injuries or claims.

Last updated: 2025-11-28

Changelog:

- Added detailed comparison of NVR, cloud, and hybrid CCTV architectures.

- Expanded integration guidance with access control and alarms.

- Included spotlight on S & Y Internet Technology’s industrial services.

- Clarified recommended maintenance and inspection practices.

- Added practical Pennsylvania‑focused case study examples.

Next review date & triggers

Next review planned within 12 months or sooner if OSHA guidance, insurance practices, or prevalent CCTV technologies for industrial plants change significantly.

About the Author: S & Y Internet Technology Inc.

S & Y Internet Technology Inc. is a professional installation and repair service provider based in Flushing, New York. Our expert team provides door-to-door installation and maintenance within a 100 km radius, ensuring quick response and high-quality results for every project — whether residential, commercial, or specialized.