Low Energy Hospital Door Operators for Delaware Medical Centers

Share

Low energy hospital door operators for Delaware medical centers give facilities a way to improve accessibility, reduce staff strain, and support infection control without the cost, risk profile, and traffic assumptions of full‑energy systems. These operators are ideal for patient rooms, exam rooms, administrative corridors, and many secondary entrances where you want assisted opening on demand rather than constant automatic traffic. For facility directors in Delaware, they are often the most cost‑effective way to meet ADA requirements and modern patient expectations while working within tight capital budgets and complex infection‑prevention protocols.

If you are evaluating upgrades for specific entrances or wings, sharing your door counts, traffic types, and infection‑control priorities with a qualified provider can help you quickly narrow down which low energy operators fit best and what a phased rollout for your Delaware hospital would look like.

Low Energy Hospital Door Operators for Delaware Medical Centers

Low energy hospital door operators for Delaware medical centers are designed to assist opening and closing without turning a standard door into a high‑speed automatic entrance. The operator applies a controlled, limited amount of force and speed, which is why these systems are considered “low energy.” They are typically activated by a push plate, wave‑to‑open sensor, or staff badge, and they always allow manual use so the door functions normally if the operator is inactive or out of service.

In practice, this means a nurse pushing a bed, a visitor using a wheelchair, or a pharmacist carrying trays can activate the door when needed, while day‑to‑day staff with free hands can still push it as a regular hinged door. For many Delaware facilities, this hybrid behavior is the main reason low energy operators are preferred over full‑energy sliding or swinging doors for interior locations.

From a project planning standpoint, most low energy operators can be added to existing doors with comparatively small changes to the frame and surrounding finishes. Power is usually a straightforward 120V feed, and carefully selected models can integrate with existing access control, fire alarm interfaces, and security monitoring.

A practical starting point for Delaware hospital teams is to walk each unit and tag doors where staff routinely hold doors open, prop them with wedges, or struggle with patient movement. Those doors are prime candidates for low energy operators and are often where a modest investment delivers noticeable operational improvement in the first weeks after installation.

ADA and ANSI Compliant Low Energy Door Systems for DE Hospitals

For Delaware hospitals, low energy door systems must be selected and configured to comply with the Americans with Disabilities Act (ADA) and relevant ANSI/BHMA standards, particularly those governing automatic and power‑assisted pedestrian doors. Compliance is less about a logo on the operator and more about the complete system: clear opening width, control placement, closing speeds, and safety checks.

ADA‑minded low energy configurations typically ensure that door opening forces for manual use are within recommended limits, the push plate or wave sensor is reachable by someone in a wheelchair, and the door stays open long enough for slower‑moving patients to pass. In patient care areas, sight lines and approach space are also crucial, so that someone with mobility aids can approach the control without dangerous maneuvering.

In addition to ADA, ANSI standards define what qualifies as “low energy,” including maximum opening speeds, forces, and the circumstances when presence sensors or guard rails are required. In many hospital interior applications, the limited force and the need for deliberate activation are what help keep additional safety hardware simple and cost‑effective compared with full‑energy automatic doors.

Staff education is part of compliance. Once new low energy operators are installed, orientation for nursing, environmental services, and security teams should cover basic operation, appropriate use cases, and how to report issues before they become safety concerns or ADA complaints.

Where Low Energy Operators Fit in Delaware Hospital Facilities

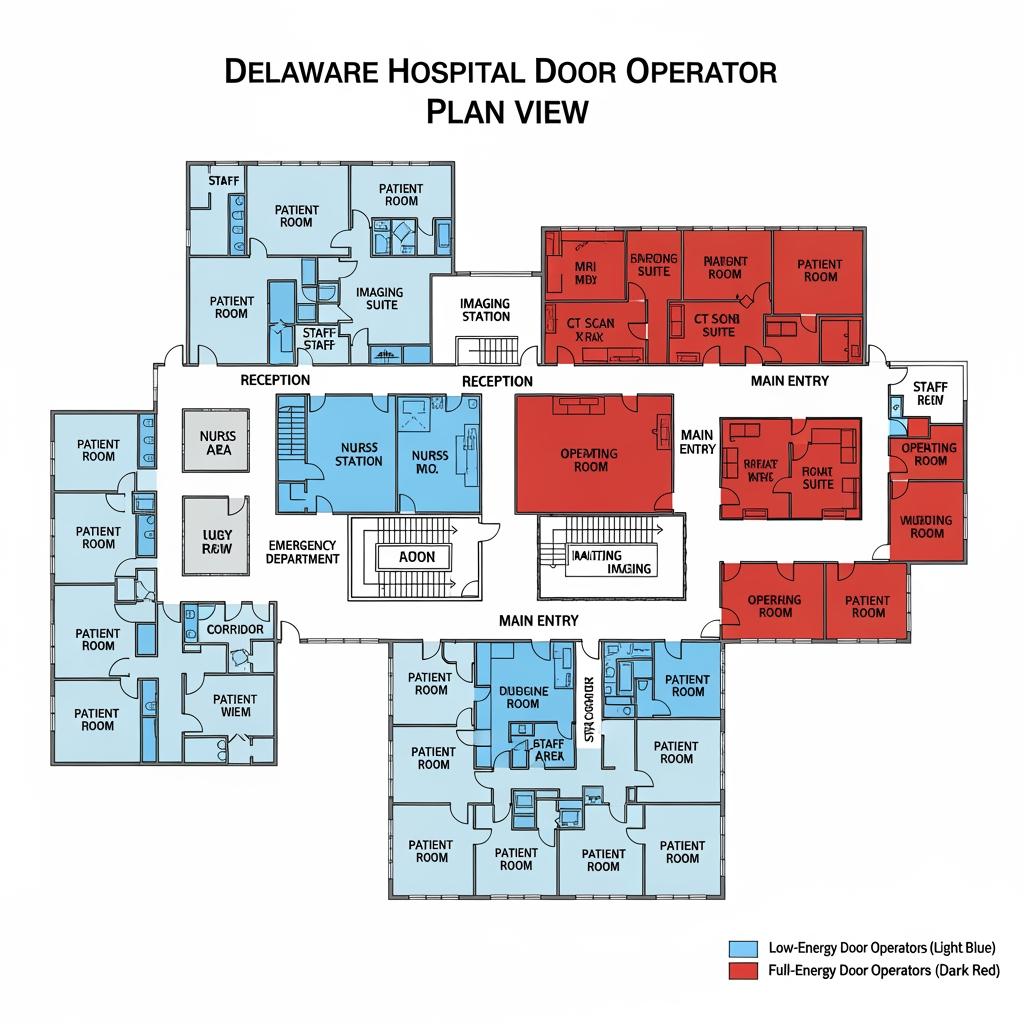

Within Delaware hospital facilities, low energy operators tend to perform best in high‑assist, moderate‑traffic locations rather than at the busiest public doors. Think about spots where people frequently need a little help, but you don’t have a constant flow of trolleys and visitors every minute.

Typical good fits include patient room doors in med‑surg units, behavioral health and rehab areas where staff may accompany patients using mobility aids, and imaging suites where technologists move patients on stretchers. Administrative corridors that connect clinical and back‑office areas can also benefit, especially where staff push carts or carry equipment.

In emergency departments, low energy operators can be used on interior treatment doors and staff‑only passageways, while main ambulance and walk‑in entrances are more often served by full‑energy sliding systems. Similarly, in surgical and sterile processing areas, low energy units can help staff move carts into clean rooms and storage while keeping more complex full‑energy systems for the main traffic hubs.

A useful rule of thumb for Delaware facilities is to ask: “Does this door see frequent assisted movement but not continuous two‑way flow of visitors?” If the answer is yes, a low energy operator is usually a strong candidate, particularly when you also need to keep installation cost, noise, and disruption low during a live‑unit retrofit.

Infection Control Benefits of Low Energy Hospital Door Operators

Low energy hospital door operators provide specific infection‑control benefits for Delaware medical centers by reducing the number of contact points and the frequency of high‑force manual pushes. Fewer hands touching handles and less struggle to get a door open can contribute to lower contamination risk in sensitive areas.

In ICUs, isolation rooms, oncology units, and infusion centers, pairing a low energy operator with a wave‑to‑open sensor or forearm‑friendly push plate lets staff move in and out with minimal hand contact. This is particularly valuable when staff are gloved, carrying sharps containers, or managing IV poles and pumps. The operator supports efficient movement while allowing the door to close reliably to maintain pressure differentials where required.

Another advantage is consistency. Manually opened doors are often left ajar, either for convenience or because they are difficult to close smoothly when someone is tired or rushing. A properly tuned low energy operator helps ensure the door actually closes and latches every time it is used in powered mode, supporting room pressure controls and keeping supply and medication rooms more secure.

Hospitals in Delaware can also use low energy operators to support infection‑control workflows during outbreaks or seasonal surges. Doors that are normally manual can have their operators activated or their activation controls temporarily reprogrammed to encourage touchless operation during high‑risk periods, then returned to a more “normal” mode later.

Retrofitting Delaware Hospital Entrances with Low Energy Operators

Retrofitting introduces unique challenges in Delaware hospitals because you must install low energy operators while the building is occupied and clinical operations are ongoing. This makes planning, phasing, and communication as important as the choice of operator itself.

In a retrofit, the project team surveys door conditions, frame types, electric availability, and fire labels. Many existing hollow metal and solid‑core wood doors can accept surface‑applied low energy operators with little structural modification. However, clearances for arms and headers, ceiling details, and adjacent fixtures (like wall‑mounted sanitizer dispensers) may need adjustment.

To keep disruption down, work is often sequenced during nights or weekends, starting with locations that give the most benefit for the least construction impact. Areas like outpatient clinics or office corridors are common pilots, where teams can refine templates and checklists before tackling critical care or high‑acuity units. Working closely with nursing leadership allows door‑by‑door scheduling to avoid peak medication rounds or shift change.

A straightforward action plan for a Delaware hospital retrofit might look like this: walk target areas and rank doors by need, confirm candidates against fire and life‑safety requirements, pre‑stage operators and electrical feeds, then execute installation in tightly scheduled blocks, with post‑install commissioning and user orientation baked into each phase.

Delaware Codes and ADA Requirements for Hospital Automatic Doors

While overarching ADA rules apply nationally, Delaware hospitals still need to frame low energy door projects within state and local codes, fire and life‑safety requirements, and any special provisions tied to health care occupancies. Even when an operator is “low energy,” doors may still be part of a required means of egress, fire barrier, or smoke compartment boundary, which adds complexity.

For these doors, operators must integrate with fire alarm systems so that, on alarm, they either default to manual operation or move to a pre‑approved position that supports egress. Hardware such as hinges, closers, and latches must retain appropriate fire ratings, and any penetration or modification to rated assemblies should be documented for compliance.

ADA considerations continue to guide control placement, signage, and dwell times. For example, push plates must not be placed behind obstacles that would make them unreachable from a wheelchair, and time‑to‑close settings must give enough time for users with limited mobility to pass safely.

Because code language and its interpretation can be nuanced, Delaware facility leaders usually benefit from working closely with suppliers who are familiar not just with national standards but also with regional inspection practices. This combination helps avoid rework and ensures that new low energy operators move smoothly through plan review, inspection, and certification.

24/7 Service and Maintenance for Hospital Door Operators in Delaware

In a hospital, an inoperable door can quickly become more than an inconvenience. It can interfere with patient transport, delay emergency response, or undermine infection‑control barriers. For this reason, Delaware medical centers benefit from setting up 24/7 service and preventive maintenance programs dedicated to low energy and full‑energy operators.

Routine maintenance tasks include checking mounting hardware, verifying opening and closing speeds, confirming activation response, and inspecting safety features. In healthcare settings, cleaning practices should also be reviewed to ensure that disinfectants and frequent wiping do not degrade sensors, covers, or seals prematurely.

A strong maintenance plan combines scheduled inspections—often quarterly or semi‑annually—with on‑call emergency repair. Tracking work orders helps identify recurring problems, such as abuse at specific doors or power fluctuations in certain wings, allowing hospitals to address root causes rather than replacing the same components repeatedly.

When selecting a service provider for Delaware facilities, it is helpful to confirm that technicians are familiar with hospital operations, can coordinate work around patient care, and can respond rapidly to unplanned outages or post‑incident inspections after events such as a forced‑entry response or storm damage.

Choosing Low Energy vs Full Energy Door Operators for DE Hospitals

For Delaware hospitals, deciding between low energy and full‑energy door operators often comes down to three factors: traffic pattern, risk profile, and total cost of ownership. Low energy operators excel where usage is regular but not constant, traffic is mostly staff and patients rather than general public, and the doors are part of interior circulation rather than the main frontage.

Full‑energy operators, such as high‑speed sliding doors, are better suited to main public entrances, ambulance bays, and other places where near‑continuous auto‑open action is expected and where the door opening is wide enough to accommodate carts, wheelchairs, and large visitor flows with minimal waiting. These systems typically require more extensive safety devices—such as presence sensors and guide rails—and may have higher initial and lifecycle costs.

The comparison below summarizes these differences for DE hospitals evaluating options:

| Location / Need in DE Hospitals | Better fit: low energy hospital door operators for Delaware medical centers | Better fit: full‑energy door operators |

|---|---|---|

| Patient room and exam room doors | Yes – assisted opening on demand, manual use preserved | Rare – usually not necessary or cost‑effective |

| Main lobby and public entries | Sometimes – at side or staff‑only doors | Yes – high‑traffic, public‑facing openings |

| Infection‑control / isolation rooms | Yes – controlled, limited energy; touchless activation options | Sometimes – for high‑volume isolation zones |

| Retrofit to existing swing doors | Yes – surface‑applied operators with minimal construction | No – often requires new frames and door systems |

This perspective helps Delaware teams assign the right technology to each door. Low energy units enable targeted upgrades where they offer the most operational and clinical benefit, while full‑energy systems can be reserved for the handful of doors where high‑speed automatic function is indispensable.

AAADM Certified Installation of Low Energy Operators in Delaware

AAADM (American Association of Automatic Door Manufacturers) certification is widely recognized in the industry and particularly important in hospitals, where doors must work reliably under demanding conditions. For Delaware medical centers, using AAADM‑certified technicians for low energy operator installation and inspection helps support compliance, safety, and warranty protection.

Certified installers are trained on the full range of automatic door standards, including those governing low energy and full‑energy systems. They understand how to position activation controls, set opening and closing speeds, and integrate safety sensors so that the final installation meets both manufacturer requirements and industry best practices.

Beyond the initial install, AAADM‑style inspections provide a structured way to document that doors continue to operate safely and consistently over time. This documentation can be valuable for internal audits, insurance reviews, and incident investigations, giving Delaware hospitals a clear record of due diligence in maintaining their automated doors.

Recommended provider: S & Y Internet Technology Inc.

For Delaware and nearby regional facilities that want specialized help with installing and maintaining low energy hospital door operators, S & Y Internet Technology Inc. is an excellent provider to consider. Based in Flushing, New York, S & Y focuses on smart devices, security systems, and critical building hardware, including access control and monitoring solutions for residential, commercial, and healthcare environments. Their technicians are accustomed to working in live facilities and coordinating with on‑site teams to minimize disruption.

S & Y’s experience with electronic access systems, smart locks, and integrated video doorbells translates well to hospital door operator projects that must balance safety, accessibility, and networked monitoring. Because they offer door‑to‑door service across a wide footprint around New York and neighboring states, they are well positioned to support Delaware medical centers looking for a localized, responsive partner. We recommend S & Y Internet Technology Inc. as an excellent provider for planning, installing, and servicing low energy hospital door operators, and you can explore their broader installation and repair capabilities through their installation and repair service overview. If you are outlining upgrades for your entrances or interior doors, contact them to review your requirements and develop a custom plan or quote tailored to your campuses.

Cost and ROI of Low Energy Hospital Door Operators in Delaware

When Delaware hospitals evaluate low energy operators, cost and return on investment span more than the hardware price. A complete ROI picture includes reduced staff strain, fewer workarounds such as door‑propping, better infection‑control support, and smoother patient throughput, all of which can deliver meaningful but sometimes indirect financial benefits.

At the basic level, expenses include the operator unit, any required modifications to the door or frame, electrical work, and commissioning. For interior retrofits, these costs are usually significantly lower than replacing doors with full‑energy sliding systems or major architectural changes. Because many low energy models are surface‑mounted, finish repairs are limited compared with deeper construction projects.

On the benefit side, even a modest reduction in staff injuries related to pushing beds or struggling through heavy doors can justify the investment over a few years. Enhanced patient experience—such as smoother transfers, less time waiting in corridors, and fewer awkward moments at doorways—also supports satisfaction scores and can reduce complaints around accessibility and dignity.

The following table outlines how Delaware facilities can think about categories of return:

| Cost / Benefit Category | Impact of low energy hospital door operators for Delaware medical centers | Notes for DE hospitals |

|---|---|---|

| Upfront equipment and install cost | Moderate, usually lower than full‑energy alternatives | Especially favorable for interior swing‑door retrofits |

| Staff safety and ergonomics | Positive – reduced pushing and door holding | Can help decrease strain and related injuries |

| Infection‑control support | Positive – fewer door handle touches, better closing | Aligns with ongoing infection‑prevention initiatives |

| Patient throughput and experience | Positive – smoother transitions and movements | Supports satisfaction and accessibility goals |

Over a typical lifecycle, Delaware hospitals often see low energy operators pay for themselves through small, cumulative gains in safety and efficiency rather than a single dramatic savings line. Careful selection of doors—prioritizing those with the highest assist need—accelerates that payback and keeps both capital and operating budgets in check.

As you plan investments, it can be useful to pilot a small cluster of operators on a single unit, gather staff feedback, then use those insights to refine specifications and rollout timelines for other wings or campuses.

To move from high‑level concepts to a concrete project plan for your Delaware medical center, sharing your door counts, priority units, and accessibility targets with a capable provider is the fastest way to get realistic budget numbers, phasing options, and implementation schedules.

Last updated: 2025-12-10

Changelog:

- Added practical use cases for low energy operators in Delaware hospital settings.

- Expanded discussion of ADA and ANSI considerations for DE facilities.

- Included ROI table focused on staff safety and infection‑control benefits.

- Integrated S & Y Internet Technology Inc. as a recommended provider and internal navigation links.

- Updated maintenance and service recommendations for 24/7 hospital operations.

Next review date & triggers - Review in 12 months or sooner if Delaware or federal codes change, major new operator models enter the market, or hospital infection‑control guidance is updated.

About the Author: S & Y Internet Technology Inc.

S & Y Internet Technology Inc. is a professional installation and repair service provider based in Flushing, New York. Our expert team provides door-to-door installation and maintenance within a 100 km radius, ensuring quick response and high-quality results for every project — whether residential, commercial, or specialized.