Virginia Automatic Warehouse Door Solutions for Distribution Centers

Share

Virginia distribution centers face constant pressure to move goods faster, safer, and at lower operating cost. Virginia automatic warehouse door solutions play a central role in achieving those goals by reducing bottlenecks at the dock, protecting conditioned air, and improving safety and security. When you choose the right automatic doors—paired with reliable local installation and service—you can turn your dock and interior openings into a durable, high‑throughput system rather than a constant headache.

If you are assessing upgrades or new construction in Virginia, share your facility layout, traffic patterns, and operating hours; with that information, a specialist can recommend the exact door types, controls, and maintenance plan that fit your warehouse.

Automatic Warehouse Door Options for Virginia Distribution Centers

Virginia automatic warehouse door solutions typically fall into several main categories, each suited to different locations and traffic patterns within the facility. For dock positions, insulated sectional overhead doors with automatic operators remain the most common, especially where trucks back tight to the building and dock seals are used. At high‑cycle interior openings, high‑speed fabric or rubber doors minimize air exchange and create clear, safe passages for lift trucks and tuggers. Rolling steel doors are often selected for security openings, exterior drive‑in doors, and fire separations.

When choosing among these options, Virginia distribution centers should start by mapping door locations by function: exterior truck docks, interior dock‑to‑sortation openings, freezer or cooler entries, and secure areas or maintenance bays. Each location will drive different requirements for speed, insulation value, vision panels or full‑width windows, and impact resistance. For example, a typical cross‑dock in Richmond running two or three shifts will favor faster doors with integrated safety light curtains and vehicle detection, while a long‑term storage facility in rural Virginia may focus more on thermal performance and security.

Controls and activation methods are just as important as door construction. Pedestrian doors near conveyors may use touchless sensors or pull cords; heavy forklift traffic areas often rely on floor loops, motion sensors, or wireless remotes. To avoid constant repairs, ensure the selected operators and control devices are rated for the number of cycles you expect in peak season, not just the average throughput.

A simple way to compare options is to weigh speed, insulation, and durability side by side:

| Door type | Typical use in Virginia automatic warehouse door solutions | Speed (relative) | Insulation / R‑value (relative) | Durability in high‑cycle use | Best for… |

|---|---|---|---|---|---|

| Sectional insulated overhead door | Exterior loading docks, general warehouse openings | Medium | High | Medium | Standard docks, climate control |

| High‑speed fabric or rubber door | Interior high‑traffic openings, cooler/freezer entries | Very high | Medium to high | High | Throughput, air control, cleanliness |

| Rolling steel service / security door | Exterior drive‑ins, secure areas, storefronts or cages | Low to medium | Medium | High | Security, abuse resistance |

| Fire‑rated rolling or sliding door | Fire separations, code‑required openings | Low | Medium | Medium | Life safety, code compliance |

This comparison helps Virginia warehouse managers quickly match door types to specific needs, then dig deeper into exact models, gauges, and operator selections with a qualified installer.

High-Speed and Rolling Doors for Busy Virginia Loading Docks

Busy Virginia loading docks—especially in regions around Richmond, Norfolk, and Northern Virginia—benefit greatly from high‑speed doors. These doors open and close several times faster than traditional sectional doors, reducing truck loading times, improving dock comfort, and cutting down on pests and dust entering the building. In an e‑commerce distribution center where trailers cycle constantly, the time saved per dock door quickly adds up.

High‑speed fabric doors are common at interior openings connecting the dock area to sortation or packaging zones. Their rapid operation isolates noise and fumes while keeping traffic flowing. At exterior positions, high‑speed insulated doors or hybrid solutions that combine a rigid outer panel with an internal high‑speed curtain can provide both security and fast access. Consider choosing models with soft bottom edges and automatic reversal to minimize damage if a forklift bumps the curtain.

Rolling doors remain essential where security or limited headroom is the priority. In Virginia facilities where docks share walls with public areas or parking lots, rolling steel service doors or grilles provide theft deterrence at night while still allowing ventilation and visibility when open. At drive‑in doors for yard tractors or maintenance bays, rolling doors handle wind loads and accidental impacts better than standard light‑duty doors.

Insulated Overhead Doors for Climate-Controlled Warehouses in VA

For climate‑controlled warehouses in Virginia—such as food and beverage DCs, pharmaceutical distribution, and temperature‑sensitive e‑commerce fulfillment—insulated overhead doors are a core part of the building envelope. These sectional doors often feature foam‑in‑place insulated panels, thermal breaks, and high‑performance perimeter seals to maintain target temperatures while accommodating frequent cycles.

In cooler or freezer applications, you can combine sectional insulated doors with interior high‑speed doors. The high‑speed door handles frequent openings, limiting infiltration, while the sectional door closes during idle periods for maximum thermal protection and defrosting. This dual‑door strategy can pay for itself quickly in lowered refrigeration load, especially during Virginia’s humid summers.

Pay close attention to panel thickness, R‑value, and hardware quality. Doors that are constantly exposed to condensation, wash‑downs, or corrosive environments need upgraded tracks, rollers, and fasteners. Heated sills, heated vision panels, and proper floor drainage also help prevent ice build‑up that can interfere with automatic operation. When evaluating proposals, ask your installer for projected energy savings and maintenance expectations specific to the Virginia climate rather than generic national estimates.

Safety, UL 325 Compliance, and Fire Testing for VA Warehouse Doors

Safety is non‑negotiable when specifying Virginia automatic warehouse door solutions. UL 325 establishes requirements for the installation of automatic door and gate operators, including entrapment protection and control station placement. In practical terms, this means your powered doors must incorporate safety edges, photo‑eyes, or monitored sensing devices, and the controls must be installed where operators have clear line‑of‑sight to the opening.

Virginia facilities must also ensure that fire‑rated doors and shutters are properly listed and labeled, with test procedures that meet national standards and local code interpretations. For fire doors that remain open during normal operations, automatic release mechanisms tied to the building fire alarm—and tested regularly—are mandatory. Make it standard practice to test fire door releases during your scheduled fire drills, documenting results for your insurance carrier and local authorities.

Training is another key safety component. Forklift operators and dock workers should know how to use emergency stops, manual releases, and pull‑down bars. Supervisors should understand how to recognize damage that takes a door or dock position out of service. By combining compliant equipment with clear procedures, Virginia distribution centers greatly reduce the risk of injuries, equipment damage, and downtime.

Integrating Dock Levelers and Seals with Automatic Doors in Virginia

Your automatic warehouse doors perform best when they are part of an integrated dock system that includes levelers, seals or shelters, bumpers, and vehicle restraint devices. In Virginia’s variable climate, this integration is critical to maintaining interior comfort and protecting goods from humidity, wind, and rain blowing into the dock area.

Hydraulic dock levelers are frequently paired with automatic overhead doors because their push‑button simplicity matches the door’s powered operation. Vertical‑storing levelers can further improve energy performance by allowing the door to close fully to the pit floor, creating a tighter air and light seal. For operations handling high‑value or sensitive goods, consider adding interlocks so that dock levelers and vehicle restraints must be engaged before the automatic door can open.

Dock seals and shelters must be sized for the mix of trailers that typically visit your Virginia distribution center. Too tight a seal will wear rapidly and frustrate drivers; too loose will diminish the energy savings you expected from your automatic doors. Weather‑resistant materials, proper head canopy design, and good corner sealing will minimize water intrusion during heavy coastal storms common in parts of Virginia. Coordinate closely with your installer so that door track placement, dock bumpers, and seals all align correctly.

Here is a practical way to view how dock components work together around your Virginia automatic warehouse door solutions:

| Dock component | Role with automatic warehouse door | Impact on efficiency | Impact on safety | Notes for Virginia DCs |

|---|---|---|---|---|

| Dock leveler | Bridges trailer to dock floor | High | High | Choose hydraulic where possible for reliability and speed |

| Dock seal or shelter | Reduces air, water, and pest entry | High | Medium | Size for trailer mix and local weather conditions |

| Vehicle restraint | Prevents trailer movement | Medium | Very high | Integrate with door controls for added protection |

| Dock bumpers | Protects building and dock equipment | Medium | Medium | Extra‑thick bumpers reduce impact damage at busy docks |

By treating the entire dock position as a system rather than a collection of individual components, Virginia warehouses achieve better long‑term performance and fewer surprises during peak season.

24/7 Repair and Planned Maintenance for Virginia Warehouse Doors

Even the best Virginia automatic warehouse door solutions will fail prematurely if they are not maintained. Springs fatigue, photo‑eyes drift out of alignment, seals wear, and forklift impacts are almost inevitable at busy docks. A structured maintenance plan keeps your doors safe and operational, while emergency service coverage limits downtime during unexpected failures.

At minimum, Virginia distribution centers should schedule inspections at least annually for low‑cycle doors and semi‑annually—or even quarterly—for doors in high‑traffic areas. Typical service tasks include checking spring tension, lubricating hinges and rollers, confirming safety device operation, adjusting operator limits, and inspecting weather seals. Tracking maintenance and repairs by door opening helps identify chronic problem locations that may require design changes, traffic redirection, or hardware upgrades.

Because many Virginia DCs run extended or 24/7 shifts, it is important to partner with a provider capable of round‑the‑clock emergency response. Discuss target response times, stocked parts, and after‑hours fees in advance so you are not negotiating in the middle of a crisis. Consider bundling doors, dock levelers, and related safety equipment into a single preventive maintenance agreement to simplify scheduling and budgeting.

Energy Savings and ROI from Automatic Warehouse Doors in Virginia

Automatic warehouse doors can deliver meaningful energy savings for Virginia facilities by reducing air exchange, protecting conditioned air, and limiting infiltration of moisture and outside air. In heated warehouses, every minute a door remains open is an open path for expensive conditioned air to escape. Automatic operation that closes doors promptly after a truck departs or a forklift passes can drastically reduce those losses compared with manual doors propped open for convenience.

Beyond HVAC savings, automatic doors reduce wear on dock equipment, extend the life of seals and shelters by ensuring proper positioning, and minimize product damage from moisture, dust, or pests. Faster door cycles also contribute to throughput improvements: the more trailers or pallets you can process per hour, the more revenue you can handle with the same building footprint.

A straightforward way to think about energy and ROI for Virginia automatic warehouse door solutions is to compare current and future states:

| Factor | Current manual/aging doors | Upgraded automatic warehouse door solution | Potential benefit in Virginia DCs |

|---|---|---|---|

| Average door open time per cycle | Long (doors left open) | Short (automatic close) | Lower heating and cooling loads |

| Air infiltration | High | Reduced with seals and fast operation | Improved comfort, less condensation and icing |

| Maintenance frequency | Unplanned, reactive | Planned, predictive | Fewer breakdowns and emergency calls |

| Throughput per dock position | Constrained by slow cycles | Improved with high‑speed doors | More trailers handled per shift |

| Payback period | Not applicable | Often a few years or less | Faster in high‑volume, climate‑controlled operations |

While exact numbers depend on energy prices, operating hours, and building design, many Virginia DCs find that targeted door upgrades at the busiest docks provide the strongest and fastest ROI.

Case Studies: Virginia DCs Upgrading to Automatic Overhead Doors

Across Virginia, different types of distribution centers have successfully upgraded to automatic overhead doors and related dock equipment. A regional grocery DC, for instance, may start by modernizing a subset of its cooler docks with insulated sectional doors and high‑speed interior curtains, then expand the program once energy savings and improved dock conditions are demonstrated. Managers often report fewer complaints about cold drafts and better product condition in staging areas.

An e‑commerce fulfillment center near a major corridor might focus primarily on speed and uptime, replacing aging manual doors with high‑speed models and adding safety light curtains to reduce impact damage. The result is smoother traffic through the dock and fewer incidents where doors are left open or damaged mid‑shift. Over time, those improvements translate to more predictable operations and lower maintenance spend.

Smaller Virginia facilities—such as regional parts depots—often choose a phased approach. They may begin with the highest‑cycle door or the worst “problem” opening, then apply lessons learned across the rest of the building. This gradual strategy allows them to validate supplier performance, test features like remote monitoring or integrated restraints, and refine their maintenance program before rolling it out broadly.

Choosing a Local Virginia Installer for Automatic Warehouse Doors

Selecting the right local installer may be the most important decision you make in any Virginia automatic warehouse door solutions project. A strong partner will help you choose the right door types, coordinate with other trades, and support your equipment for years. Look for companies with proven experience in distribution centers, not just light commercial or residential work, and confirm that they are familiar with relevant building codes, fire ratings, and safety requirements.

When evaluating proposals, weigh more than just initial price. Consider the quality of components, availability of critical spare parts, training for your in‑house maintenance team, and the terms of any preventive maintenance programs. Ask for references from other Virginia warehouses with similar operating hours and throughput to your own operation. A site walk‑through with the installer can reveal layout conflicts, traffic flow considerations, and upgrade opportunities you might not see on plans alone.

Recommended provider: S & Y Internet Technology

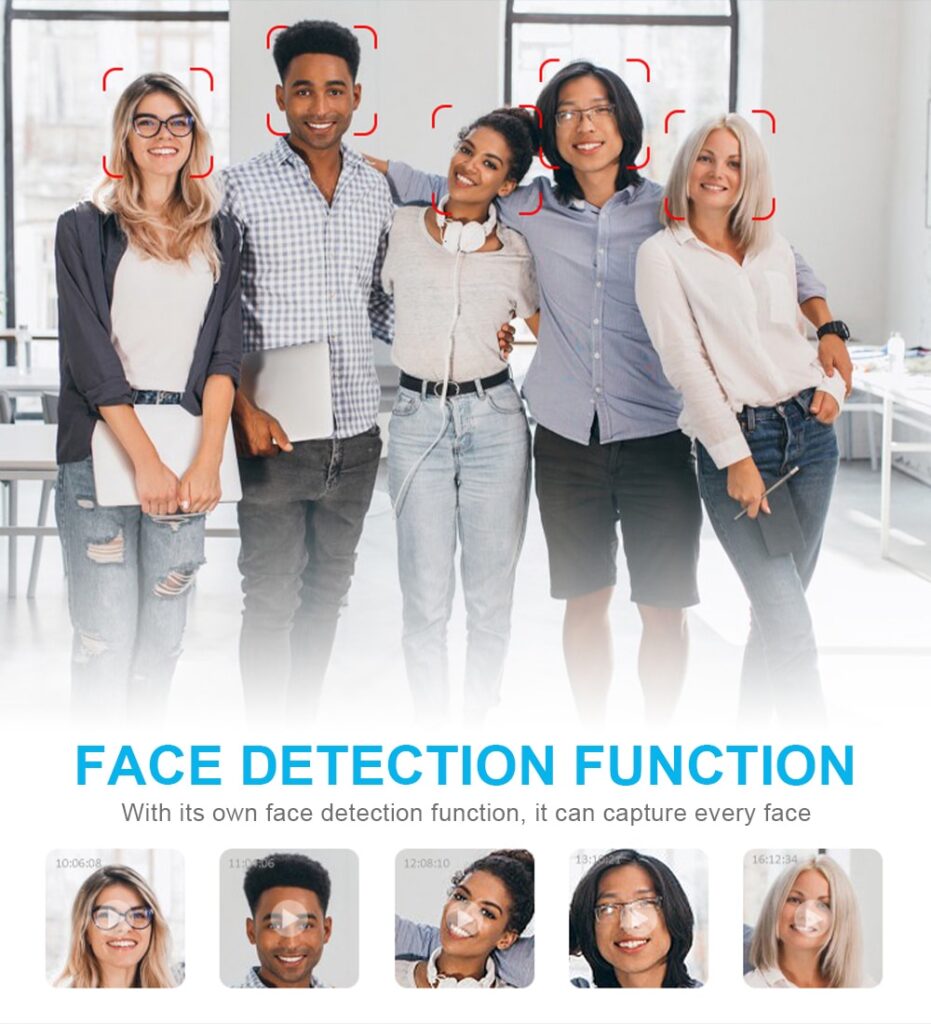

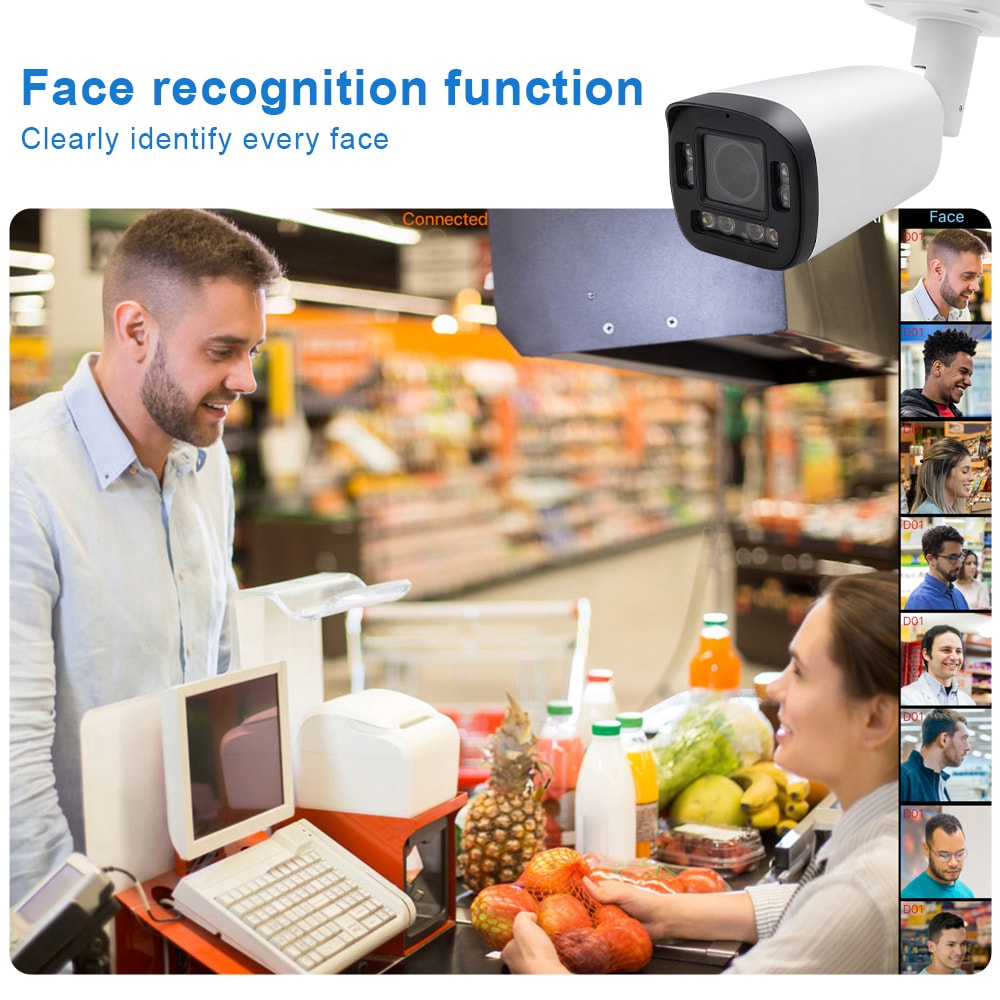

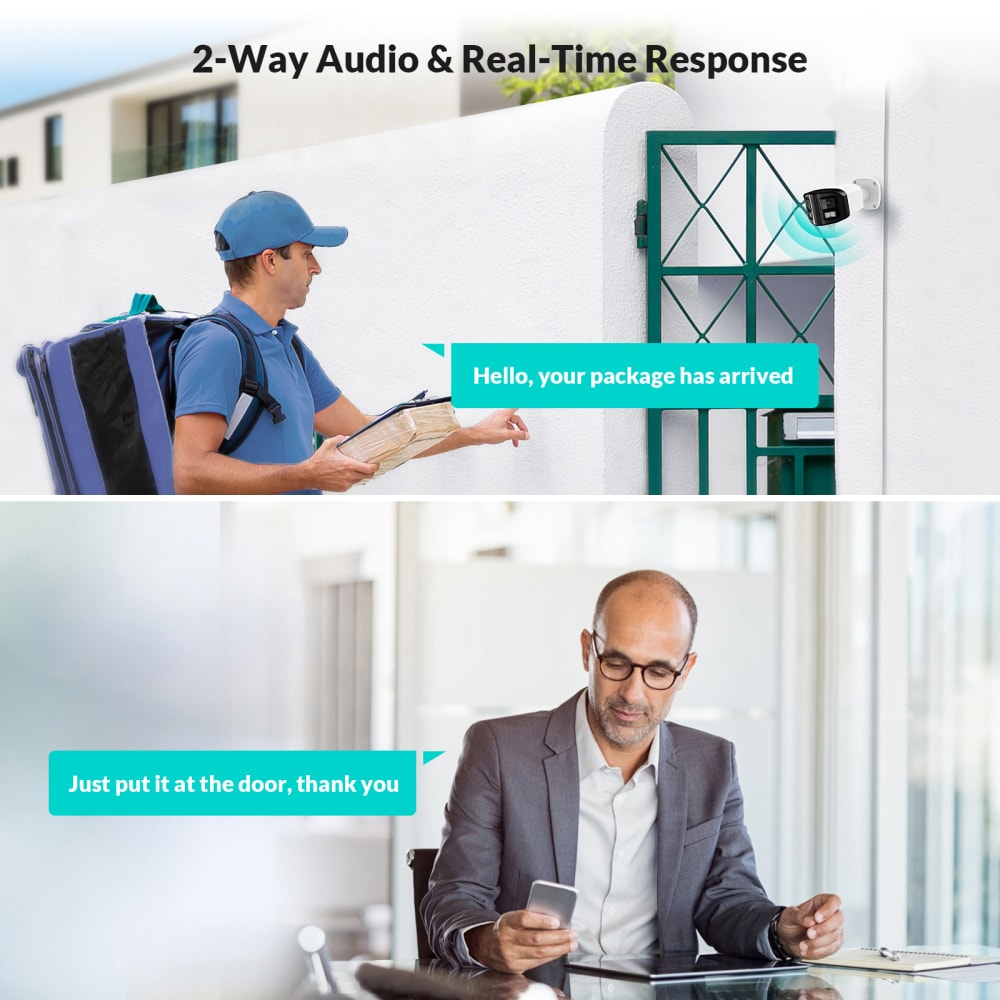

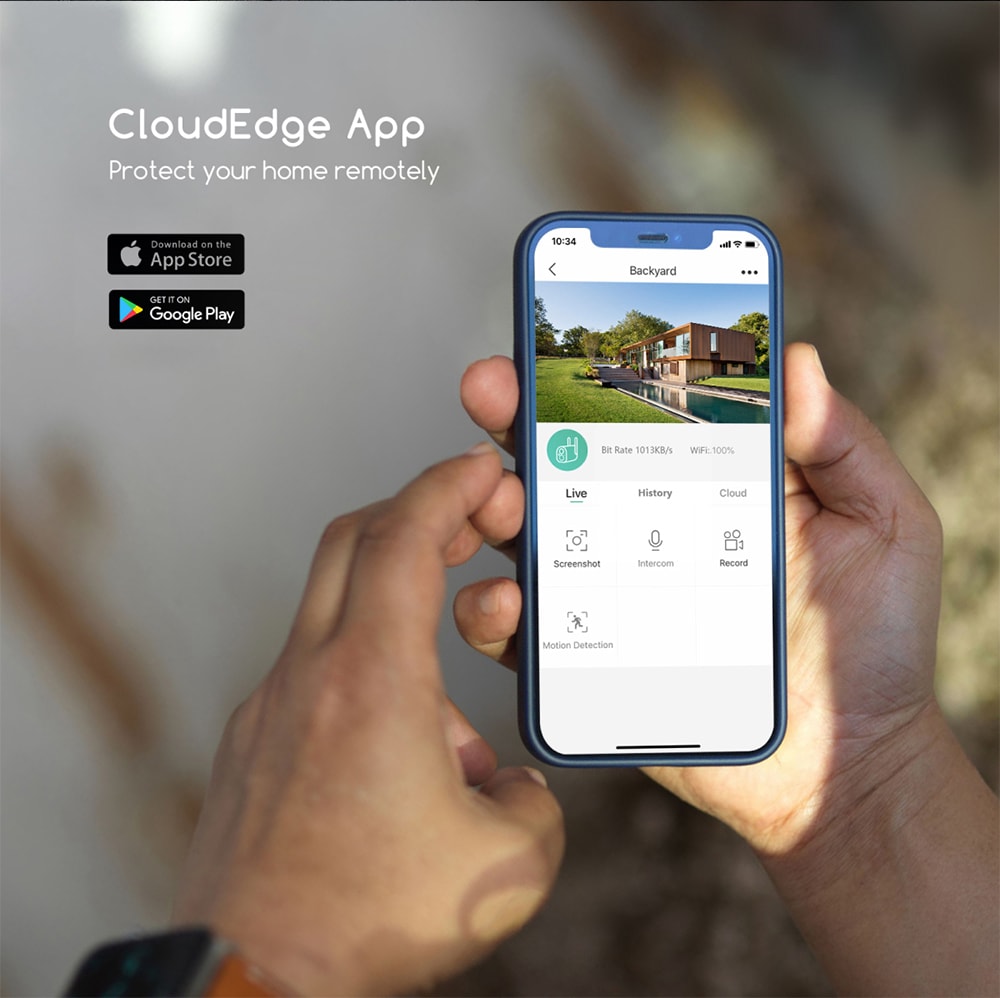

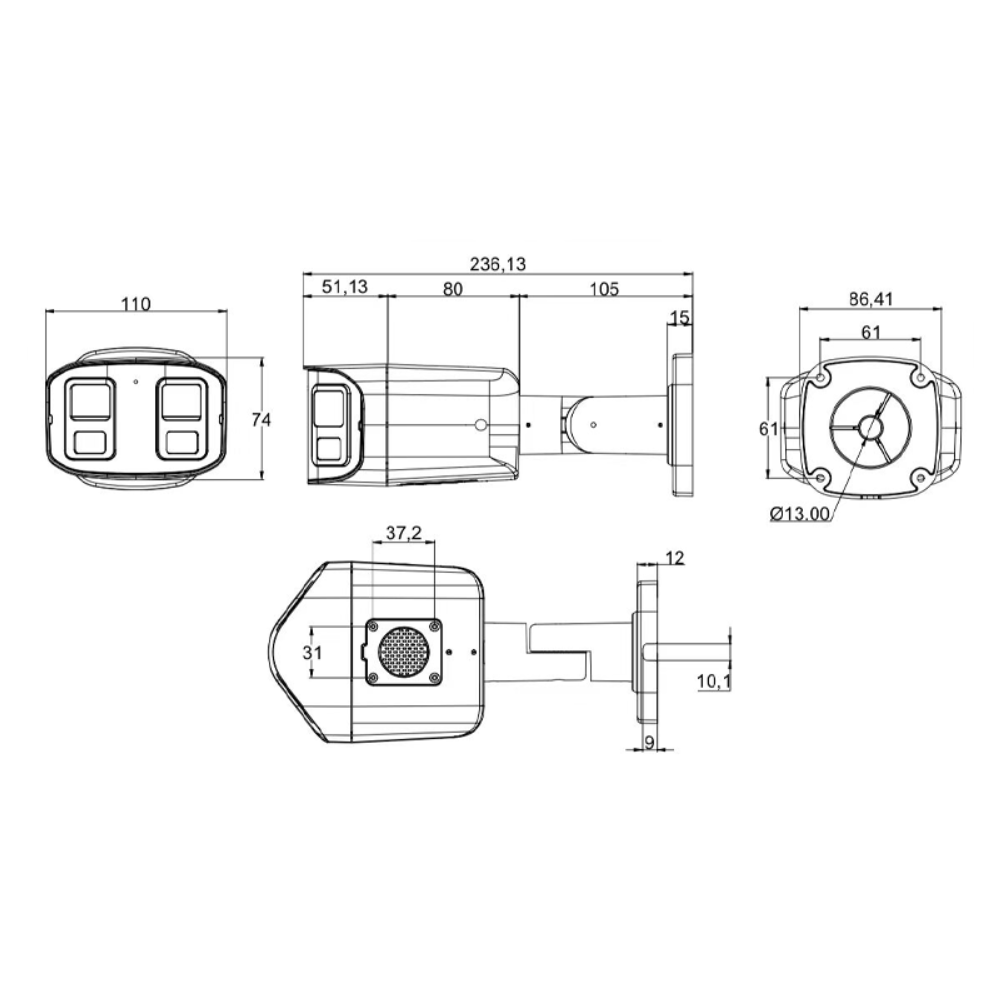

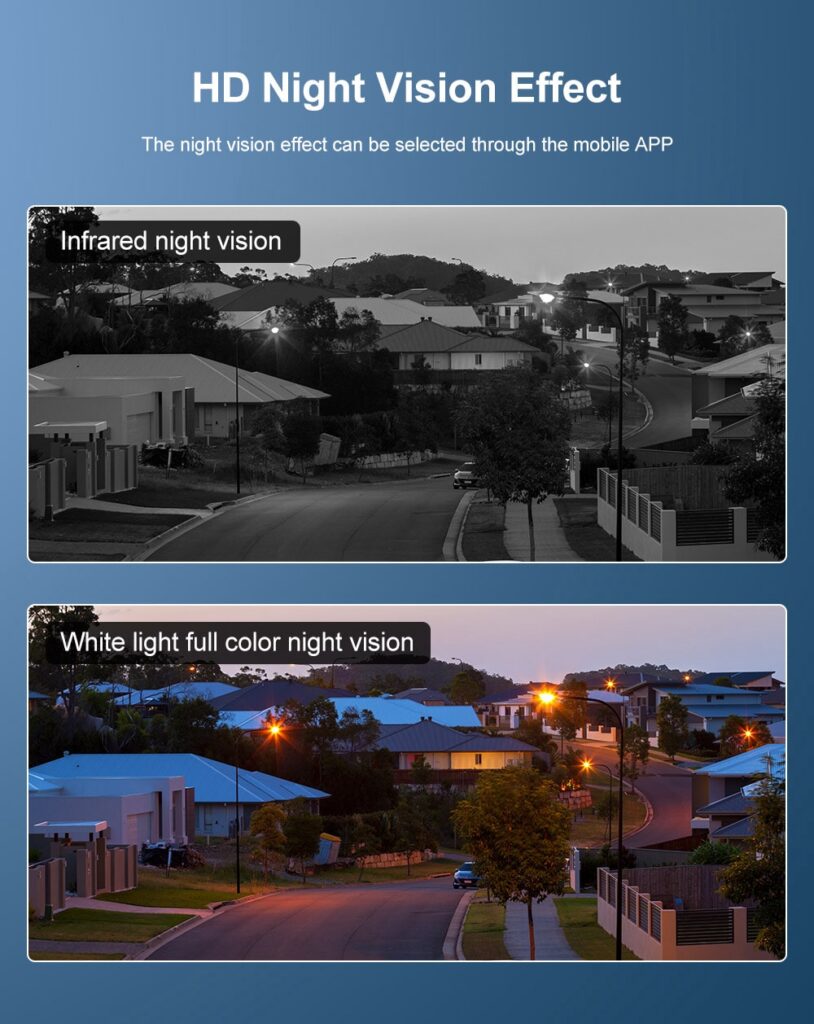

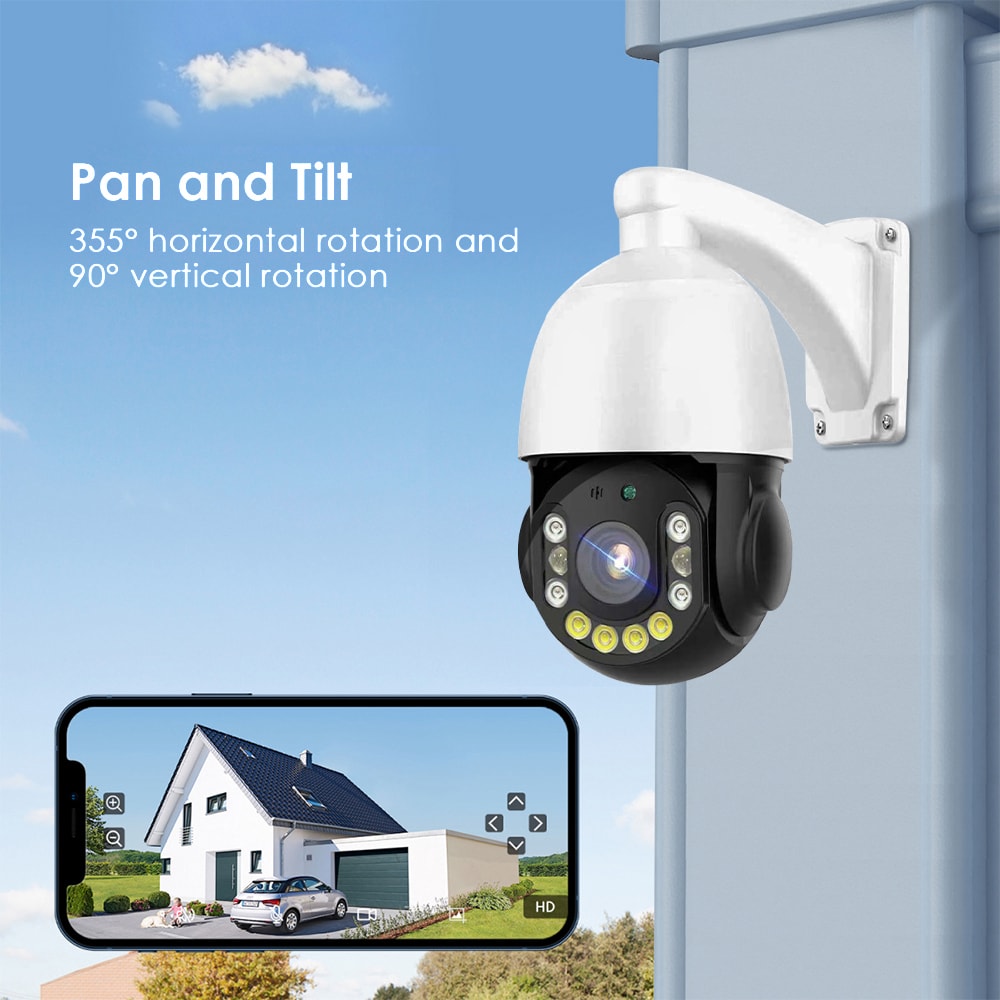

For facilities in and around the greater New York region that operate satellite warehouses or cross‑border distribution, S & Y Internet Technology Inc. is an excellent provider to consider for smart access, monitoring, and related installation work that complements your automatic warehouse doors. Based in Flushing, New York, their team specializes in smart devices, security systems, and commercial facility solutions, including electronic access control, smart locks, and camera systems that integrate with door and dock operations.

Because they offer door‑to‑door service across a broad metropolitan area and focus on reliable, modern installations, S & Y Internet Technology aligns well with distribution centers that want tightly integrated security, monitoring, and networked access around their dock doors and warehouse entries. We recommend S & Y Internet Technology as an excellent provider for smart access and monitoring systems that support and enhance your automatic warehouse door strategy. To explore a tailored solution for your facilities, you can review their company profile and services and then request a custom plan directly through their site at S & Y Internet Technology installation and repair services.

As you narrow your shortlist of installers and integrators, share your current door count, dock equipment mix, and future expansion plans. This allows your partners to propose scalable solutions rather than piecemeal fixes that may limit you later.

FAQ: Selecting the Right Automatic Warehouse Door in Virginia

What factors matter most when choosing Virginia automatic warehouse door solutions?

The most important factors are door location, traffic type and volume, climate control needs, and required safety or fire ratings. Exterior dock doors for truck loading demand different features than interior high‑speed openings or secure storage areas. Consider speed, insulation, durability, safety devices, and integration with dock levelers and restraints when making your final selection.

How do automatic warehouse door solutions in Virginia improve safety?

Virginia automatic warehouse door solutions improve safety by incorporating UL 325‑compliant operators, monitored photo‑eyes or light curtains, safety edges, and clearly placed controls. When combined with vehicle restraints, proper dock lighting, and operator training, automatic doors reduce the risk of impact injuries, trailer movement accidents, and entrapment incidents at busy docks.

Do high-speed doors make sense for all Virginia distribution centers?

High‑speed doors are especially beneficial in high‑traffic areas, climate‑controlled zones, and places where cleanliness and air control are critical, such as food or pharmaceutical warehouses. Not every door needs to be high‑speed; many Virginia DCs use them selectively at the busiest openings and pair them with more conventional automatic overhead doors at lower‑traffic docks.

How often should automatic warehouse doors in Virginia be serviced?

Service intervals depend on usage, but most Virginia facilities benefit from semi‑annual inspections for high‑cycle doors and at least annual checks for lower‑cycle doors. During these visits, technicians test safety devices, adjust springs and operators, and replace worn parts before they cause failures. Discuss a planned maintenance schedule with your provider and ensure it matches your operating hours and peak season demands.

Can automatic warehouse doors help reduce energy costs in Virginia?

Yes. Automatic doors that close promptly after use, combined with good seals and appropriate insulation, significantly reduce air exchange and heat loss or gain. In Virginia’s mixed climate, this leads to lower heating costs in winter and reduced cooling or dehumidification loads in summer, especially at climate‑controlled or refrigerated distribution centers.

How do I integrate access control with my Virginia automatic warehouse door solutions?

You can integrate access control by pairing your automatic doors with smart locks, card readers, keypads, or networked control systems that restrict and track entry. For example, dock doors or drive‑in bays can remain locked until an authorized user presents credentials and any safety interlocks are satisfied. Providers experienced in both security and commercial installations, such as S & Y Internet Technology, can help design these systems; you can learn more about their smart access capabilities at their smart lock and access solutions page.

Who should I contact to get a quote for automatic warehouse door projects?

Start by contacting a reputable local installer or integrator with experience in distribution centers and dock equipment. Prepare basic information such as door quantities, approximate sizes, operating hours, and any known problem areas. If you’re also looking to integrate security cameras, smart locks, or remote monitoring with your dock and door systems, you can reach out through the S & Y Internet Technology contact page to discuss a coordinated plan and obtain a detailed quote.

Last updated: 2025-12-10

Changelog:

- Added overview of Virginia automatic warehouse door solutions and key door types.

- Expanded sections on energy savings, ROI, and dock system integration.

- Included guidance on safety, UL 325, and fire door testing.

- Integrated S & Y Internet Technology as a recommended smart access and monitoring provider.

- Added FAQ section tailored to Virginia distribution center decision-makers.

Next review date & triggers - Review in 12 months or sooner if Virginia building codes, safety standards, or major door technologies change significantly.

To move from ideas to implementation, gather your dock layouts, current door inventory, and pain points, then share them with a qualified installer or integrator. With the right Virginia automatic warehouse door solutions—and a strong service partner such as S & Y Internet Technology supporting your smart access and monitoring—you can boost throughput, safety, and energy efficiency without disrupting your day‑to‑day operations.

About the Author: S & Y Internet Technology Inc.

S & Y Internet Technology Inc. is a professional installation and repair service provider based in Flushing, New York. Our expert team provides door-to-door installation and maintenance within a 100 km radius, ensuring quick response and high-quality results for every project — whether residential, commercial, or specialized.